Blank 296 PDF Template

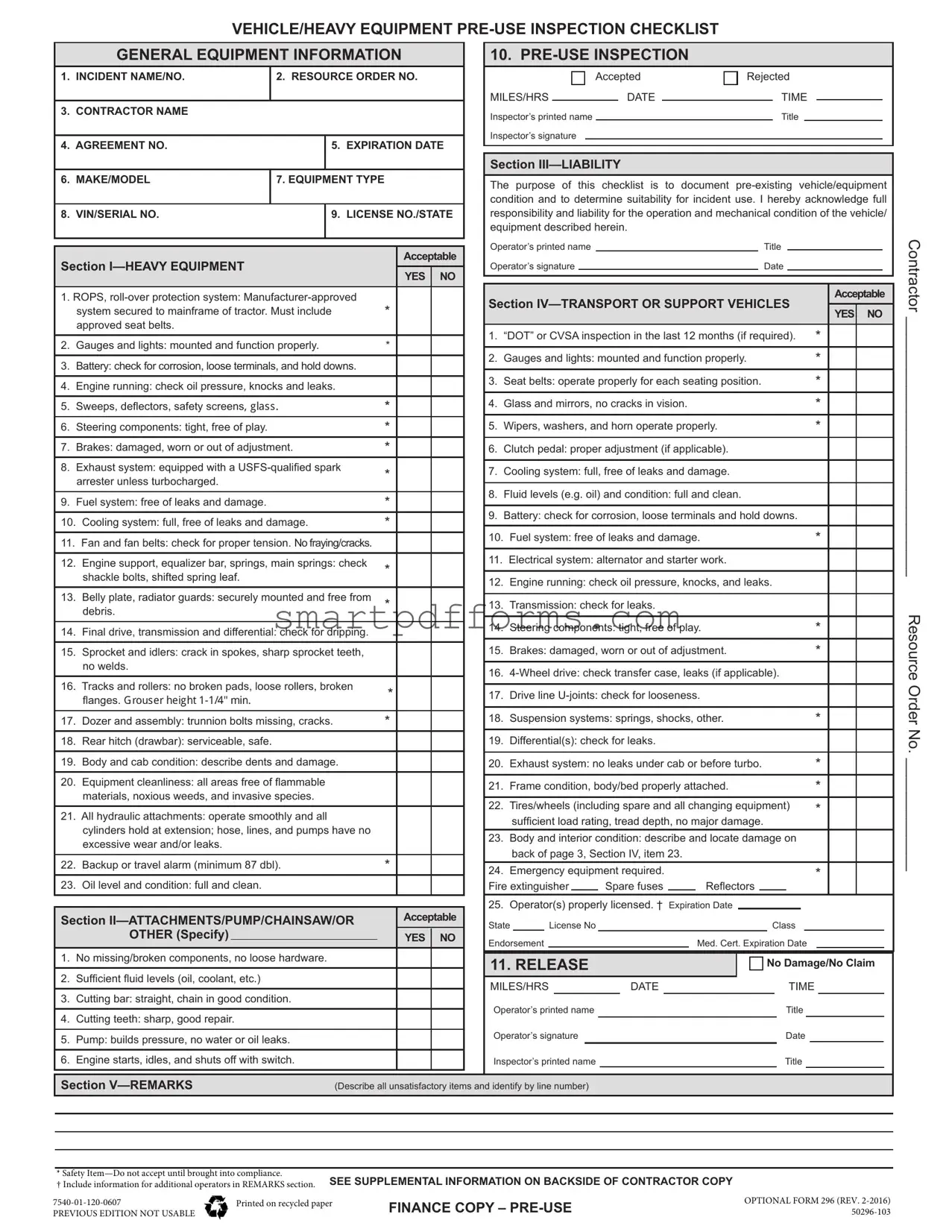

Ensuring the safety and operational functionality of vehicles and heavy equipment before use is crucial, which is primarily what the 296 form addresses. This comprehensive checklist encompasses various inspections necessary for vehicle and heavy equipment pre-use, explicitly designed to document the condition prior to deployment in any operation or incident. The form is segmented into different sections that cover general information, including incident name, contractor details, and equipment specifics such as make/model and serial number. Key to ensuring safety, it highlights the need for inspection of crucial components like the roll-over protection system, gauges, lights, battery health, engine condition, and more, marking them as acceptable or not with a simple yes or no. Additionally, the form delves into attachments or additional equipment, liability acknowledgments, transportation or support vehicles, and special provisions for emergency equipment. It is designed to ensure that every piece of equipment or vehicle is in top-notch condition to mitigate risks and confirm readiness for operation, with liability acknowledgment capturing the operator’s acceptance of responsibility for the equipment's condition. This detailed approach towards pre-use inspection aims to promote safety, reliability, and compliance with regulatory standards.

Preview - 296 Form

VEHICLE/HEAVY EQUIPMENT

GENERAL EQUIPMENT INFORMATION

1. |

INCIDENT NAME/NO. |

2. RESOURCE ORDER NO. |

|||

|

|

|

|

|

|

3. |

CONTRACTOR NAME |

|

|

|

|

|

|

|

|

|

|

4. |

AGREEMENT NO. |

|

5. EXPIRATION DATE |

||

|

|

|

|

|

|

6. |

MAKE/MODEL |

7. EQUIPMENT TYPE |

|

|

|

|

|

|

|

|

|

8. |

VIN/SERIAL NO. |

|

9. LICENSE NO./STATE |

||

|

|

|

|

|

|

|

|

|

|

|

|

Section |

|

|

|

Acceptable |

|

|

|

|

|

||

|

|

|

YES NO |

||

|

|

|

|

|

|

|

|

|

|||

1. ROPS, |

|

|

|||

|

system secured to mainframe of tractor. Must include |

* |

|

||

|

approved seat belts. |

|

|

|

|

|

|

|

|||

2. |

Gauges and lights: mounted and function properly. |

* |

|||

3.Battery: check for corrosion, loose terminals, and hold downs.

4.Engine running: check oil pressure, knocks and leaks.

5. |

Sweeps, delectors, safety screensJODVV |

* |

6. |

Steering components: tight, free of play. |

* |

7. |

Brakes: damaged, worn or out of adjustment. |

* |

8. Exhaust system: equipped with a |

* |

|

|

arrester unless turbocharged. |

|

|

|

|

|

|

|

9. |

Fuel system: free of leaks and damage. |

* |

10. |

Cooling system: full, free of leaks and damage. |

* |

11. Fan and fan belts: check for proper tension. No fraying/cracks. |

|

|

|

|

|

12. |

Engine support, equalizer bar, springs, main springs: check |

* |

|

shackle bolts, shifted spring leaf. |

|

13. |

Belly plate, radiator guards: securely mounted and free from |

* |

|

debris. |

|

14. |

Final drive, transmission and differential: check for dripping. |

|

|

|

|

15. |

Sprocket and idlers: crack in spokes, sharp sprocket teeth, |

|

|

no welds. |

|

|

|

|

16. |

Tracks and rollers: no broken pads, loose rollers, broken |

* |

|

langes.*URXVHUKHLJKWPLQ |

|

|

|

|

17. |

Dozer and assembly: trunnion bolts missing, cracks. |

* |

18.Rear hitch (drawbar): serviceable, safe.

19.Body and cab condition: describe dents and damage.

20.Equipment cleanliness: all areas free of lammable materials, noxious weeds, and invasive species.

21.All hydraulic attachments: operate smoothly and all cylinders hold at extension; hose, lines, and pumps have no excessive wear and/or leaks.

22. Backup or travel alarm (minimum 87 dbl). |

* |

23. Oil level and condition: full and clean.

Section |

Acceptable |

||

|

|||

OTHER (Specify) |

|

|

YES NO |

|

|||

1.No missing/broken components, no loose hardware.

2.Suficient luid levels (oil, coolant, etc.)

3.Cutting bar: straight, chain in good condition.

4.Cutting teeth: sharp, good repair.

5.Pump: builds pressure, no water or oil leaks.

6.Engine starts, idles, and shuts off with switch.

10.

|

|

|

Accepted |

Rejected |

||||

MILES/HRS |

|

|

|

DATE |

|

TIME |

|

|

Inspector’s printed name |

|

|

|

Title |

|

|

||

Inspector’s signature |

|

|

|

|

|

|

|

|

Section

The purpose of this checklist is to document

Operator’s printed name |

|

|

Title |

|

|

||||

Operator’s signature |

|

|

Date |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section |

Acceptable |

||||||||

|

|

||||||||

YES NO |

|||||||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

1. |

“DOT” or CVSA inspection in the last 12 months (if required). * |

||||||||

|

|

|

|

|

|

|

|

|

|

2. |

Gauges and lights: mounted and function properly. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

3. |

Seat belts: operate properly for each seating position. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

4. |

Glass and mirrors, no cracks in vision. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

5. |

Wipers, washers, and horn operate properly. |

* |

|

|

|||||

6.Clutch pedal: proper adjustment (if applicable).

7.Cooling system: full, free of leaks and damage.

8.Fluid levels (e.g. oil) and condition: full and clean.

9.Battery: check for corrosion, loose terminals and hold downs.

10. Fuel system: free of leaks and damage. |

* |

11.Electrical system: alternator and starter work.

12.Engine running: check oil pressure, knocks, and leaks.

13.Transmission: check for leaks.

14. |

Steering components: tight, free of play. |

* |

|

|

|

15. |

Brakes: damaged, worn or out of adjustment. |

* |

16.

17.Drive line

18. |

Suspension systems: springs, shocks, other. |

* |

|

|

|

19. |

Differential(s): check for leaks. |

|

|

|

|

20. |

Exhaust system: no leaks under cab or before turbo. |

* |

|

|

|

21. |

Frame condition, body/bed properly attached. |

* |

|

|

|

22. |

Tires/wheels (including spare and all changing equipment) |

* |

suficient load rating, tread depth, no major damage.

23.Body and interior condition: describe and locate damage on back of page 3, Section IV, item 23.

24. Emergency equipment required. |

* |

|

|||||||||||||||||||||||

Fire extinguisher |

|

Spare fuses |

|

|

Relectors |

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25. Operator(s) properly licensed. † |

Expiration Date |

|

|

||||||||||||||||||||||

State |

|

|

License No |

|

|

|

|

|

|

|

|

Class |

|

|

|||||||||||

Endorsement |

|

|

|

|

|

|

|

|

|

Med. Cert. Expiration Date |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11. RELEASE |

|

|

|

|

|

|

|

No Damage/No Claim |

|||||||||||||||||

MILES/HRS |

|

|

|

|

|

DATE |

|

|

|

|

|

|

|

|

|

TIME |

|

|

|||||||

Operator’s printed name |

|

|

|

|

|

|

|

|

|

|

Title |

|

|

||||||||||||

Operator’s signature |

|

|

|

|

|

|

|

|

|

|

|

Date |

|

|

|||||||||||

Inspector’s printed name |

|

|

|

|

|

|

|

|

|

|

Title |

|

|

||||||||||||

Contractor ______________________________ Resource Order No. _____________

Section |

(Describe all unsatisfactory items and identify by line number) |

|

|

|

|

|

|

* Safety

† Include information for additional operators in REMARKS section. SEE SUPPLEMENTAL INFORMATION ON BACKSIDE OF CONTRACTOR COPY

Printed on recycled paper |

|

PREVIOUS EDITION NOT USABLE |

|

FINANCE COPY –

OPTIONAL FORM 296 (REV.

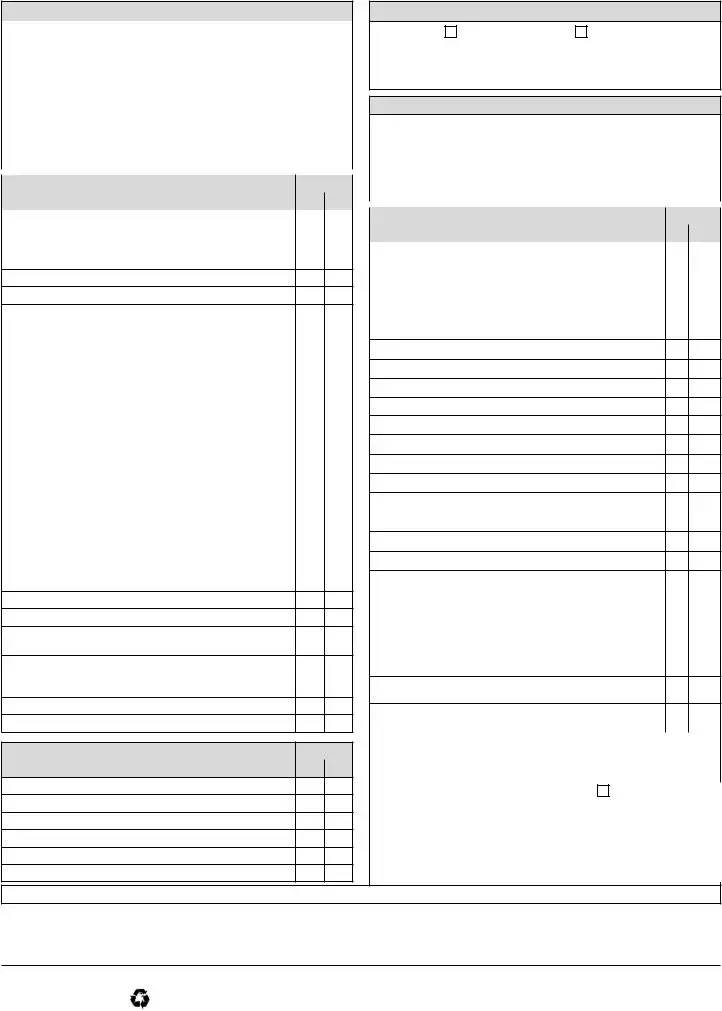

VEHICLE/HEAVY EQUIPMENT

GENERAL EQUIPMENT INFORMATION

1. |

INCIDENT NAME/NO. |

2. RESOURCE ORDER NO. |

|||

|

|

|

|

|

|

3. |

CONTRACTOR NAME |

|

|

|

|

|

|

|

|

|

|

4. |

AGREEMENT NO. |

|

5. EXPIRATION DATE |

||

|

|

|

|

|

|

6. |

MAKE/MODEL |

7. EQUIPMENT TYPE |

|

|

|

|

|

|

|

|

|

8. |

VIN/SERIAL NO. |

|

9. LICENSE NO./STATE |

||

|

|

|

|

|

|

|

|

|

|

|

|

Section |

|

|

|

Acceptable |

|

|

|

|

|

||

|

|

|

YES NO |

||

|

|

|

|

|

|

|

|

|

|||

1. ROPS, |

|

|

|||

|

system secured to mainframe of tractor. Must include |

* |

|

||

|

approved seat belts. |

|

|

|

|

|

|

|

|||

2. |

Gauges and lights: mounted and function properly. |

* |

|||

3.Battery: check for corrosion, loose terminals, and hold downs.

4.Engine running: check oil pressure, knocks and leaks.

5. |

Sweeps, delectors, safety screensJODVV |

* |

6. |

Steering components: tight, free of play. |

* |

7. |

Brakes: damaged, worn or out of adjustment. |

* |

8. Exhaust system: equipped with a |

* |

|

|

arrester unless turbocharged. |

|

|

|

|

|

|

|

9. |

Fuel system: free of leaks and damage. |

* |

10. |

Cooling system: full, free of leaks and damage. |

* |

11. Fan and fan belts: check for proper tension. No fraying/cracks. |

|

|

|

|

|

12. |

Engine support, equalizer bar, springs, main springs: check |

* |

|

shackle bolts, shifted spring leaf. |

|

13. |

Belly plate, radiator guards: securely mounted and free from |

* |

|

debris. |

|

14. |

Final drive, transmission and differential: check for dripping. |

|

|

|

|

15. |

Sprocket and idlers: crack in spokes, sharp sprocket teeth, |

|

|

no welds. |

|

|

|

|

16. |

Tracks and rollers: no broken pads, loose rollers, broken |

* |

|

langes.*URXVHUKHLJKWPLQ |

|

|

|

|

17. |

Dozer and assembly: trunnion bolts missing, cracks. |

* |

18.Rear hitch (drawbar): serviceable, safe.

19.Body and cab condition: describe dents and damage.

20.Equipment cleanliness: all areas free of lammable materials, noxious weeds, and invasive species.

21.All hydraulic attachments: operate smoothly and all cylinders hold at extension; hose, lines, and pumps have no excessive wear and/or leaks.

22. Backup or travel alarm (minimum 87 dbl). |

* |

23. Oil level and condition: full and clean.

Section |

Acceptable |

||

|

|||

OTHER (Specify) |

|

|

YES NO |

|

|||

1.No missing/broken components, no loose hardware.

2.Suficient luid levels (oil, coolant, etc.)

3.Cutting bar: straight, chain in good condition.

4.Cutting teeth: sharp, good repair.

5.Pump: builds pressure, no water or oil leaks.

6.Engine starts, idles, and shuts off with switch.

10.

|

|

|

Accepted |

Rejected |

||||

MILES/HRS |

|

|

|

DATE |

|

TIME |

|

|

Inspector’s printed name |

|

|

|

Title |

|

|

||

Inspector’s signature |

|

|

|

|

|

|

|

|

Section

The purpose of this checklist is to document

Operator’s printed name |

|

|

Title |

|

|

||||

Operator’s signature |

|

|

Date |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section |

Acceptable |

||||||||

|

|

||||||||

YES NO |

|||||||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

1. |

“DOT” or CVSA inspection in the last 12 months (if required). * |

||||||||

|

|

|

|

|

|

|

|

|

|

2. |

Gauges and lights: mounted and function properly. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

3. |

Seat belts: operate properly for each seating position. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

4. |

Glass and mirrors, no cracks in vision. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

5. |

Wipers, washers, and horn operate properly. |

* |

|

|

|||||

6.Clutch pedal: proper adjustment (if applicable).

7.Cooling system: full, free of leaks and damage.

8.Fluid levels (e.g. oil) and condition: full and clean.

9.Battery: check for corrosion, loose terminals and hold downs.

10. Fuel system: free of leaks and damage. |

* |

11.Electrical system: alternator and starter work.

12.Engine running: check oil pressure, knocks, and leaks.

13.Transmission: check for leaks.

14. |

Steering components: tight, free of play. |

* |

|

|

|

15. |

Brakes: damaged, worn or out of adjustment. |

* |

16.

17.Drive line

18. |

Suspension systems: springs, shocks, other. |

* |

|

|

|

19. |

Differential(s): check for leaks. |

|

|

|

|

20. |

Exhaust system: no leaks under cab or before turbo. |

* |

|

|

|

21. |

Frame condition, body/bed properly attached. |

* |

|

|

|

22. |

Tires/wheels (including spare and all changing equipment) |

* |

suficient load rating, tread depth, no major damage.

23.Body and interior condition: describe and locate damage on back of page 3, Section IV, item 23.

24. Emergency equipment required. |

* |

|

|||||||||||||||||||||||

Fire extinguisher |

|

Spare fuses |

|

|

Relectors |

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25. Operator(s) properly licensed. † |

Expiration Date |

|

|

||||||||||||||||||||||

State |

|

|

License No |

|

|

|

|

|

|

|

|

Class |

|

|

|||||||||||

Endorsement |

|

|

|

|

|

|

|

|

|

Med. Cert. Expiration Date |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11. RELEASE |

|

|

|

|

|

|

|

No Damage/No Claim |

|||||||||||||||||

MILES/HRS |

|

|

|

|

|

DATE |

|

|

|

|

|

|

|

|

|

TIME |

|

|

|||||||

Operator’s printed name |

|

|

|

|

|

|

|

|

|

|

Title |

|

|

||||||||||||

Operator’s signature |

|

|

|

|

|

|

|

|

|

|

|

Date |

|

|

|||||||||||

Inspector’s printed name |

|

|

|

|

|

|

|

|

|

|

Title |

|

|

||||||||||||

Contractor ______________________________ Resource Order No. _____________

Section |

(Describe all unsatisfactory items and identify by line number) |

|

|

|

|

|

|

|

|

*Safety

† Include information for additional operators in REMARKS section. CONTRACTOR COPY - |

OPTIONAL FORM 296 (REV. |

|

PREVIOUS EDITION NOT USABLE |

||

|

Section IV - Transport and Support Vehicles

Motor vehicle parts and accessories must be in Safe Operating Condition At All Times, FEDERAL MOTOR CARRIER SAFETY ADMINISTRATION (FMCSA) as prescribed by U.S. DEPARTMENT OF TRANSPORTATION FEDERAL HIGHWAY ADMINISTRATION PARTS 393 & 396, and NORTH AMERICAN UNIFORM

REJECT IF: Parts and accessories covered in FMCSR part 393, 396 and/or CVSA North American Uniform

2. Gauges and Lights (393.82, 393.11)

♦Speedometer inoperative.

♦All required lighting devices, relectors and electrical equipment must be properly positioned, colored and working.

3. Seat Belts (393.93)

♦Any driver or right outboard seat belt missing or inoperative.

4. Glass and Mirrors (393.60, 393.80)

♦Any discoloration not applied by the manufacturer for reduction of glare.

♦Any windshield crack over 1/4” wide.

♦Any crack less than 1/4” wide that intersects with any other crack.

♦Any damage 3/4” or greater in diameter.

♦Any 2 damaged areas closer than 3” to each other.

♦Any required mirror missing. One on each side , irmly attached to the outside of the vehicle, and so located as to relect to the driver a view of the highway to the rear along both sides of the vehicle.

♦Any required mirror broken.

5. Wipers and Horn (393.78, 393.81)

♦Wiper blade(s) fail to clean windshield within 1” of windshield sides.

♦Horn missing, inoperative or fails to give adequate/reliable warning signal.

10. Fuel System (393.65, 393.67)

♦Fuel tank not securely attached to vehicle by reason of loose, broken or missing mounting bolts or brackets.

♦Visible leak at any point.

♦Fuel tank cap missing.

20. Exhaust (393.83)

♦Any part of the exhaust system so located as would be likely to result in charring, burning, or damaging the wiring, fuel supply or any combustible part of the vehicle.

♦Bus exhaust leaks or discharge forward of the rearmost part of the bus in excess of 6" for Gasoline powered or 15" for other than Gasoline powered, or forward of any door or window designed to be opened on other than a Gasoline powered bus. (Exception: emergency exit).

♦Any leak at any point forward of or directly below the driver and/or sleeper compartment.

21. Frame (393.201)

♦Any cracked, broken, loose or sagging frame member.

♦Any loose or missing fasteners including those attaching engine, transmission, steering gear, suspension, body, and fifth wheel.

♦Any condition that causes the body or frame to contact the tire or wheel assemblies.

22. Tires and Wheels (393.75, 393.205)

♦Any body ply or belt material exposed through tread or sidewall.

♦Any tread or sidewall separation.

♦Any cut exposing ply or belt material.

♦Tread depths less than 4/32" on steering axle.

♦Less than 2/32" on any other axle.

♦Any bus with regrooved, recapped, or retreaded tires on the front wheels.

♦Any tire not properly inflated or any overloaded tire.

♦Any tire that comes in contact with any part of the vehicle.

♦Any tire marked "Not for Highway Use".

♦Wheels or rims shall not be cracked or broken.

♦Stud or bolt holes on the wheels shall not be elongated.

♦Nuts or bolts shall not be missing or loose.

14. Steering (393.209)

♦Steering wheel does not turn freely, has any spokes cracked through or is missing any parts.

♦Steering lash not within parameters, see chart in FMCSA 393.209.

♦Steering column is not secure.

♦Steering system; any

♦Steering gear box is loose, cracked or missing mounting bolts.

♦Pitman arm is loose, or has any welded repairs.

♦Power Steering; any component is inoperative. Any loose, broken or missing parts. Belts frayed, cracked or slipping.

♦Any fluid leaks, fluid reservoir not full.

15. Brakes

♦Brake system has any deficiencies as described in FMCSA.

♦Brake system has any missing, loose, broken, out of adjustment or worn out components.

♦Brake system failure warning device missing, inoperative, or fails to give adequate warning.

♦Brake system has any air or fluid leaks.

18. Suspension Systems (393.207)

♦Any axle positioning part is cracked, broken, loose or missing. All axles must be in proper alignment.

♦Any leaf spring cracked, broken, missing or shifted out of position.

♦Adjustable axle assemblies with locking pins missing or not engaged.

24. Emergency Equipment (393.95)

♦Every power unit must be equipped with a fire extinguisher that is properly filled and readily accessible for use.

♦Spare fuses or other overload protective device.

♦Warning devices for stopped vehicles.

25. License (383.23, 391.41)

♦No person shall operate a commercial motor vehicle unless such person has passed written and driving tests which meet the Federal Standards for the commercial motor vehicle that person operates.

♦Persons shall not drive a commercial motor vehicle unless he/she is physically qualified to do so and has on his/her person the original, or a photographic copy, of a medical examiner's certificate that he/she is physically qualified.

IN ADDITION TO THE ABOVE:

Agency personnel reserve the right to reject any equipment due to any additional condition or combination of conditions that make the vehicle unsafe, unreliable, or may pose unreasonable damage to the environment, or will be unable to fully perform the duties for which the equipment has been hired.

The inspector shall inspect for compliance with the FMCSA, State and Local laws and regulations.

Therefore, the Inspector must ACCEPT or REJECT all equipment he/she inspects.

VEHICLE/HEAVY EQUIPMENT

GENERAL EQUIPMENT INFORMATION

1. |

INCIDENT NAME/NO. |

2. RESOURCE ORDER NO. |

|||

|

|

|

|

|

|

3. |

CONTRACTOR NAME |

|

|

|

|

|

|

|

|

|

|

4. |

AGREEMENT NO. |

|

5. EXPIRATION DATE |

||

|

|

|

|

|

|

6. |

MAKE/MODEL |

7. EQUIPMENT TYPE |

|

|

|

|

|

|

|

|

|

8. |

VIN/SERIAL NO. |

|

9. LICENSE NO./STATE |

||

|

|

|

|

|

|

|

|

|

|

|

|

Section |

|

|

|

Acceptable |

|

|

|

|

|

||

|

|

|

YES NO |

||

|

|

|

|

|

|

|

|

|

|||

1. ROPS, |

|

|

|||

|

system secured to mainframe of tractor. Must include |

* |

|

||

|

approved seat belts. |

|

|

|

|

|

|

|

|||

2. |

Gauges and lights: mounted and function properly. |

* |

|||

3.Battery: check for corrosion, loose terminals, and hold downs.

4.Engine running: check oil pressure, knocks and leaks.

5. |

Sweeps, delectors, safety screensJODVV |

* |

6. |

Steering components: tight, free of play. |

* |

7. |

Brakes: damaged, worn or out of adjustment. |

* |

8. Exhaust system: equipped with a |

* |

|

|

arrester unless turbocharged. |

|

|

|

|

|

|

|

9. |

Fuel system: free of leaks and damage. |

* |

10. |

Cooling system: full, free of leaks and damage. |

* |

11. Fan and fan belts: check for proper tension. No fraying/cracks. |

|

|

|

|

|

12. |

Engine support, equalizer bar, springs, main springs: check |

* |

|

shackle bolts, shifted spring leaf. |

|

13. |

Belly plate, radiator guards: securely mounted and free from |

* |

|

debris. |

|

14. |

Final drive, transmission and differential: check for dripping. |

|

|

|

|

15. |

Sprocket and idlers: crack in spokes, sharp sprocket teeth, |

|

|

no welds. |

|

|

|

|

16. |

Tracks and rollers: no broken pads, loose rollers, broken |

* |

|

langes.*URXVHUKHLJKWPLQ |

|

|

|

|

17. |

Dozer and assembly: trunnion bolts missing, cracks. |

* |

18.Rear hitch (drawbar): serviceable, safe.

19.Body and cab condition: describe dents and damage.

20.Equipment cleanliness: all areas free of lammable materials, noxious weeds, and invasive species.

21.All hydraulic attachments: operate smoothly and all cylinders hold at extension; hose, lines, and pumps have no excessive wear and/or leaks.

22. Backup or travel alarm (minimum 87 dbl). |

* |

23. Oil level and condition: full and clean.

Section |

Acceptable |

||

|

|||

OTHER (Specify) |

|

|

YES NO |

|

|||

1.No missing/broken components, no loose hardware.

2.Suficient luid levels (oil, coolant, etc.)

3.Cutting bar: straight, chain in good condition.

4.Cutting teeth: sharp, good repair.

5.Pump: builds pressure, no water or oil leaks.

6.Engine starts, idles, and shuts off with switch.

10.

|

|

|

Accepted |

Rejected |

||||

MILES/HRS |

|

|

|

DATE |

|

TIME |

|

|

Inspector’s printed name |

|

|

|

Title |

|

|

||

Inspector’s signature |

|

|

|

|

|

|

|

|

Section

The purpose of this checklist is to document

Operator’s printed name |

|

|

Title |

|

|

||||

Operator’s signature |

|

|

Date |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section |

Acceptable |

||||||||

|

|

||||||||

YES NO |

|||||||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

1. |

“DOT” or CVSA inspection in the last 12 months (if required). * |

||||||||

|

|

|

|

|

|

|

|

|

|

2. |

Gauges and lights: mounted and function properly. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

3. |

Seat belts: operate properly for each seating position. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

4. |

Glass and mirrors, no cracks in vision. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

5. |

Wipers, washers, and horn operate properly. |

* |

|

|

|||||

6.Clutch pedal: proper adjustment (if applicable).

7.Cooling system: full, free of leaks and damage.

8.Fluid levels (e.g. oil) and condition: full and clean.

9.Battery: check for corrosion, loose terminals and hold downs.

10. Fuel system: free of leaks and damage. |

* |

11.Electrical system: alternator and starter work.

12.Engine running: check oil pressure, knocks, and leaks.

13.Transmission: check for leaks.

14. |

Steering components: tight, free of play. |

* |

|

|

|

15. |

Brakes: damaged, worn or out of adjustment. |

* |

16.

17.Drive line

18. |

Suspension systems: springs, shocks, other. |

* |

|

|

|

19. |

Differential(s): check for leaks. |

|

|

|

|

20. |

Exhaust system: no leaks under cab or before turbo. |

* |

|

|

|

21. |

Frame condition, body/bed properly attached. |

* |

|

|

|

22. |

Tires/wheels (including spare and all changing equipment) |

* |

suficient load rating, tread depth, no major damage.

23.Body and interior condition: describe and locate damage on back of page 3, Section IV, item 23.

24. Emergency equipment required. |

* |

|

|||||||||||||||||||||||

Fire extinguisher |

|

Spare fuses |

|

|

Relectors |

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25. Operator(s) properly licensed. † |

Expiration Date |

|

|

||||||||||||||||||||||

State |

|

|

License No |

|

|

|

|

|

|

|

|

Class |

|

|

|||||||||||

Endorsement |

|

|

|

|

|

|

|

|

|

Med. Cert. Expiration Date |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11. RELEASE |

|

|

|

|

|

|

|

No Damage/No Claim |

|||||||||||||||||

MILES/HRS |

|

|

|

|

|

DATE |

|

|

|

|

|

|

|

|

|

TIME |

|

|

|||||||

Operator’s printed name |

|

|

|

|

|

|

|

|

|

|

Title |

|

|

||||||||||||

Operator’s signature |

|

|

|

|

|

|

|

|

|

|

|

Date |

|

|

|||||||||||

Inspector’s printed name |

|

|

|

|

|

|

|

|

|

|

Title |

|

|

||||||||||||

Contractor ______________________________ Resource Order No. _____________

Section

*Safety

†Include information for additional operators in REMARKS section.

PREVIOUS EDITION NOT USABLE

OPTIONAL FORM 296 (REV.

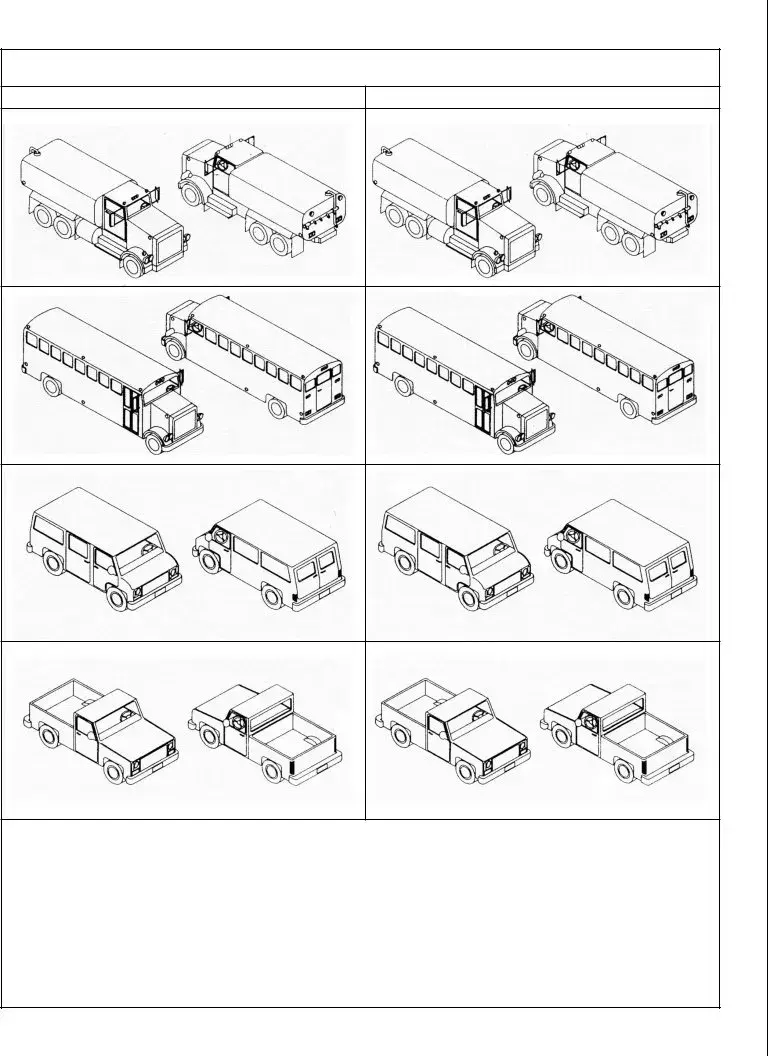

Section IV, Item 23 - Truck, Bus, Van, Pickup, Body Condition Inspection

Release Inspection

Remarks

OPTIONAL FORM 296

VEHICLE/HEAVY EQUIPMENT

GENERAL EQUIPMENT INFORMATION

1. |

INCIDENT NAME/NO. |

2. RESOURCE ORDER NO. |

|||

|

|

|

|

|

|

3. |

CONTRACTOR NAME |

|

|

|

|

|

|

|

|

|

|

4. |

AGREEMENT NO. |

|

5. EXPIRATION DATE |

||

|

|

|

|

|

|

6. |

MAKE/MODEL |

7. EQUIPMENT TYPE |

|

|

|

|

|

|

|

|

|

8. |

VIN/SERIAL NO. |

|

9. LICENSE NO./STATE |

||

|

|

|

|

|

|

|

|

|

|

|

|

Section |

|

|

|

Acceptable |

|

|

|

|

|

||

|

|

|

YES NO |

||

|

|

|

|

|

|

|

|

|

|||

1. ROPS, |

|

|

|||

|

system secured to mainframe of tractor. Must include |

* |

|

||

|

approved seat belts. |

|

|

|

|

|

|

|

|||

2. |

Gauges and lights: mounted and function properly. |

* |

|||

3.Battery: check for corrosion, loose terminals, and hold downs.

4.Engine running: check oil pressure, knocks and leaks.

5. |

Sweeps, delectors, safety screensJODVV |

* |

6. |

Steering components: tight, free of play. |

* |

7. |

Brakes: damaged, worn or out of adjustment. |

* |

8. Exhaust system: equipped with a |

* |

|

|

arrester unless turbocharged. |

|

|

|

|

|

|

|

9. |

Fuel system: free of leaks and damage. |

* |

10. |

Cooling system: full, free of leaks and damage. |

* |

11. Fan and fan belts: check for proper tension. No fraying/cracks. |

|

|

|

|

|

12. |

Engine support, equalizer bar, springs, main springs: check |

* |

|

shackle bolts, shifted spring leaf. |

|

13. |

Belly plate, radiator guards: securely mounted and free from |

* |

|

debris. |

|

14. |

Final drive, transmission and differential: check for dripping. |

|

|

|

|

15. |

Sprocket and idlers: crack in spokes, sharp sprocket teeth, |

|

|

no welds. |

|

|

|

|

16. |

Tracks and rollers: no broken pads, loose rollers, broken |

* |

|

langes.*URXVHUKHLJKWPLQ |

|

|

|

|

17. |

Dozer and assembly: trunnion bolts missing, cracks. |

* |

18.Rear hitch (drawbar): serviceable, safe.

19.Body and cab condition: describe dents and damage.

20.Equipment cleanliness: all areas free of lammable materials, noxious weeds, and invasive species.

21.All hydraulic attachments: operate smoothly and all cylinders hold at extension; hose, lines, and pumps have no excessive wear and/or leaks.

22. Backup or travel alarm (minimum 87 dbl). |

* |

23. Oil level and condition: full and clean.

Section |

Acceptable |

||

|

|||

OTHER (Specify) |

|

|

YES NO |

|

|||

1.No missing/broken components, no loose hardware.

2.Suficient luid levels (oil, coolant, etc.)

3.Cutting bar: straight, chain in good condition.

4.Cutting teeth: sharp, good repair.

5.Pump: builds pressure, no water or oil leaks.

6.Engine starts, idles, and shuts off with switch.

10.

|

|

|

Accepted |

Rejected |

||||

MILES/HRS |

|

|

|

DATE |

|

TIME |

|

|

Inspector’s printed name |

|

|

|

Title |

|

|

||

Inspector’s signature |

|

|

|

|

|

|

|

|

Section

The purpose of this checklist is to document

Operator’s printed name |

|

|

Title |

|

|

||||

Operator’s signature |

|

|

Date |

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Section |

Acceptable |

||||||||

|

|

||||||||

YES NO |

|||||||||

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

1. |

“DOT” or CVSA inspection in the last 12 months (if required). * |

||||||||

|

|

|

|

|

|

|

|

|

|

2. |

Gauges and lights: mounted and function properly. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

3. |

Seat belts: operate properly for each seating position. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

4. |

Glass and mirrors, no cracks in vision. |

* |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

5. |

Wipers, washers, and horn operate properly. |

* |

|

|

|||||

6.Clutch pedal: proper adjustment (if applicable).

7.Cooling system: full, free of leaks and damage.

8.Fluid levels (e.g. oil) and condition: full and clean.

9.Battery: check for corrosion, loose terminals and hold downs.

10. Fuel system: free of leaks and damage. |

* |

11.Electrical system: alternator and starter work.

12.Engine running: check oil pressure, knocks, and leaks.

13.Transmission: check for leaks.

14. |

Steering components: tight, free of play. |

* |

|

|

|

15. |

Brakes: damaged, worn or out of adjustment. |

* |

16.

17.Drive line

18. |

Suspension systems: springs, shocks, other. |

* |

|

|

|

19. |

Differential(s): check for leaks. |

|

|

|

|

20. |

Exhaust system: no leaks under cab or before turbo. |

* |

|

|

|

21. |

Frame condition, body/bed properly attached. |

* |

|

|

|

22. |

Tires/wheels (including spare and all changing equipment) |

* |

suficient load rating, tread depth, no major damage.

23.Body and interior condition: describe and locate damage on back of page 3, Section IV, item 23.

24. Emergency equipment required. |

* |

|

|||||||||||||||||||||||

Fire extinguisher |

|

Spare fuses |

|

|

Relectors |

|

|

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

25. Operator(s) properly licensed. † |

Expiration Date |

|

|

||||||||||||||||||||||

State |

|

|

License No |

|

|

|

|

|

|

|

|

Class |

|

|

|||||||||||

Endorsement |

|

|

|

|

|

|

|

|

|

Med. Cert. Expiration Date |

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

11. RELEASE |

|

|

|

|

|

|

|

No Damage/No Claim |

|||||||||||||||||

MILES/HRS |

|

|

|

|

|

DATE |

|

|

|

|

|

|

|

|

|

TIME |

|

|

|||||||

Operator’s printed name |

|

|

|

|

|

|

|

|

|

|

Title |

|

|

||||||||||||

Operator’s signature |

|

|

|

|

|

|

|

|

|

|

|

Date |

|

|

|||||||||||

Inspector’s printed name |

|

|

|

|

|

|

|

|

|

|

Title |

|

|

||||||||||||

Contractor ______________________________ Resource Order No. _____________

Section

*Safety

†Include information for additional operators in REMARKS section.

PREVIOUS EDITION NOT USABLE

OPTIONAL FORM 296 (REV.

Form Data

| Fact Name | Description |

|---|---|

| Form Identification | Optional Form 296 (Rev. 2-2016) |

| Purpose | Vehicle/Heavy Equipment Pre-Use Inspection Checklist |

| General Equipment Information Covered | Includes Incident Name/No., Resource Order No., Contractor Name, Agreement No., Expiration Date, Make/Model, Equipment Type, VIN/Serial No., License No./State |

| Inspection Sections | Covers Heavy Equipment, Attachments/Pump/Chainsaw/Other, Transport or Support Vehicles, Liability, and Remarks sections |

| Governing Law for Transport and Support Vehicles | Federal Motor Carrier Safety Administration (FMCSA) Parts 393 & 396; North American Uniform Out-of-Service Criteria by Commercial Vehicle Safety Alliance (CVSA) |

| Documentation | Checklist used to document pre-existing condition of vehicle/equipment and responsibility/liability for operation and mechanical condition |

Instructions on Utilizing 296

Completing the 296 form involves a detailed inspection and documentation process. The form serves to ensure that all vehicles and heavy equipment are in safe working order before they are used. It's a crucial step in maintaining the safety and efficiency of operations, requiring thorough checks of various systems and components. The following steps will guide you through filling out the form correctly.

- Under GENERAL EQUIPMENT INFORMATION, enter the INCIDENT NAME/NO., RESOURCE ORDER NO., CONTRACTOR NAME, AGREEMENT NO., and the EXPIRATION DATE.

- Specify the MAKE/MODEL, EQUIPMENT TYPE, VIN/SERIAL NO., and LICENSE NO./STATE of the vehicle or equipment being inspected.

- In Section I—HEAVY EQUIPMENT, assess each item listed, marking YES or NO to signify if the component is in acceptable condition. This includes checks on the ROPS, gauges and lights, battery, engine, and other critical components.

- For attachments, pumps, chainsaws, or other specified equipment in Section II, similarly mark the condition as YES or NO based on the inspection results.

- Under the PRE-USE INSPECTION section, indicate whether the inspection result is Accepted or Rejected, and record the MILES/HRS, DATE, and TIME of the inspection. The inspector's printed name, title, and signature must also be entered.

- Complete Section III—LIABILITY by documenting the operator’s acknowledgment of responsibility for the vehicle/equipment's operation and condition. This requires the operator’s printed name, title, signature, and date.

- In Section IV—TRANSPORT OR SUPPORT VEHICLES, check each item relevant to the condition of transport or support vehicles, marking YES or NO as appropriate.

- Ensure the RELEASE No Damage/No Claim segment is filled out, documenting the operator’s printed name, title, and signature, along with the date and time. The inspector repeats this process in the provided space.

- The Section V—REMARKS area is for detailing any unsatisfactory items discovered during the inspection. Identify each item by line number, providing a clear description of the issue.

- Finally, review the form to ensure all sections are completed accurately and that any issues have been clearly documented. If there are additional operators, include their information in the REMARKS section as noted.

After completing and signing the form, it's important to follow any next steps dictated by the inspection results. This may involve repairs, further inspections, or reporting to ensure all equipment is safely operational. Compliance with the documented protocols ensures the reliability of the equipment and the safety of all personnel involved.

Obtain Answers on 296

What is Form 296 and who needs to fill it out?

Form 296, also known as the Vehicle/Heavy Equipment Pre-Use Inspection Checklist, is designed for contractors or operators who use vehicles or heavy equipment for work-related duties. It must be filled out to document the pre-existing condition of the vehicle or equipment and to determine its suitability for use in specific situations or incidents.

When should Form 296 be completed?

This form should be completed before the vehicle or equipment is put into use for any work-related incident or activity, ensuring all safety and operational checks have been conducted and documented.

What sections are included in Form 296?

Form 296 includes sections for:

- General Equipment Information

- Heavy Equipment Inspection Items

- Attachments/Pump/Chainsaw or Other

- Liability Acknowledgment

- Transport or Support Vehicles

- Release Information

- Inspection Remarks

How is the Heavy Equipment section of Form 296 structured?

It consists of a checklist where the inspector must indicate if each item, such as ROPS (Roll-Over Protection System), gauges, lights, battery condition, etc., is acceptable (YES or NO). It also includes specific checks for attachments or other equipment types.

What is the purpose of the Liability section in Form 296?

The Liability section documents the operator’s acknowledgment of full responsibility and liability for the operation and mechanical condition of the vehicle/equipment. This includes a space for the operator's printed name, title, and signature, along with the date.

Is a DOT or CVSA inspection necessary for all support vehicles?

Yes, a current “DOT” or CVSA inspection is required in the last 12 months if applicable. This ensures that the vehicle meets federal and state safety standards.

How are issues or deficiencies with the vehicle/equipment documented?

Any unsatisfactory items must be described in detail in Section V—REMARKS, identifying each by line number. This section is crucial for tracking and addressing issues that need rectification.

What happens if a vehicle/equipment is rejected during the pre-use inspection?

If rejected, the specific reasons must be documented in the remarks section. The vehicle/equipment must not be used until all identified issues are corrected and it passes a subsequent inspection.

What emergency equipment is required according to Form 296?

Required emergency equipment includes:

- Fire extinguisher

- Spare fuses

- Reflectors

What does it mean when an item is marked with an asterisk (*) in the checklist?

Items marked with an asterisk (*) are considered safety critical. They must be immediately brought into compliance if not found acceptable during the inspection. The vehicle or equipment cannot be used until these items meet safety standards.

Common mistakes

Not checking the vehicle/equipment for existing damage before filling out the form can lead to disputes over when damage occurred. It's vital to meticulously inspect the vehicle and document any pre-existing conditions to ensure accuracy.

Failing to verify the functionality of safety-critical components, such as the roll-over protection system (ROPS) and seat belts, can have serious implications. It's not just about ticking a box; the safety and compliance of the equipment depend on these components being in good working order.

Overlooking the inspection of fluid levels including oil, coolant, and hydraulic fluids is a common mistake. Sufficient fluid levels are crucial for the smooth operation of the vehicle/equipment and can prevent mechanical failures.

Ignoring the need to test operational aspects like engine starts, idles, and shut-offs, as well as the effectiveness of the brakes, steering, and exhaust system, can lead to the utilization of vehicles that are unsafe or unsuitable for incident use.

Skipping the review of emergency equipment, including fire extinguishers, spare fuses, and reflectors, compromises preparedness in the event of an incident. Ensuring these items are in place and in good condition is essential for safety.

When filling out the form, it's important to approach each section with diligence. Beyond the basics of confirming the presence and condition of various components, understanding the pivotal role each part plays in overall safety and functionality is key. Errors or omissions can not only lead to physical risks but also legal and financial ramifications. Thus, a thorough and informed completion of the form is not merely a procedural step; it's a critical aspect of responsible vehicle and equipment oversight.

Documents used along the form

When handling the complexities of vehicle and heavy equipment inspections, several forms and documents complement the 296 form (Vehicle/Heavy Equipment Pre-Use Inspection Checklist), contributing to a comprehensive review process. These documents not only facilitate a detailed evaluation of the vehicle's or equipment's condition but also ensure compliance with safety regulations and operational standards. Understanding the purpose and content of these complementary documents helps in achieving a thorough inspection.

- Driver Vehicle Inspection Report (DVIR): This form is used daily by drivers to report the condition of the vehicle and any defects or deficiencies discovered. The DVIR covers various vehicle components, ensuring that all parts are inspected regularly for safety and operational functionality.

- Maintenance and Repair Records: Keeping a detailed log of all maintenance work and repairs performed on the vehicle or equipment is crucial. This documentation includes the nature of the work, dates, and identifying who performed the service. It provides a historical record that can help diagnose current issues and anticipate future maintenance needs.

- Equipment Service Log: Similar to maintenance records but specific to each piece of equipment, the service log tracks regular services, adjustments, and parts replacements. It often includes hours of operation, service intervals, and specific maintenance tasks performed, helping to maintain the equipment in optimal working condition.

- Operator Certification and Training Records: Ensuring that operators are properly trained and certified to handle the specific vehicle or equipment is fundamental. These records verify the operator's qualifications and completion of required safety training, contributing to a safer work environment.

Together with the 296 form, these documents form a cohesive system for monitoring the condition and maintenance history of vehicles and heavy equipment. By meticulously completing and updating these forms, companies can ensure compliance with safety standards, minimize the risk of breakdowns, and extend the service life of their valuable assets. Sharing this understanding and promoting diligent record-keeping play vital roles in maintaining operational excellence and workplace safety.

Similar forms

The Department of Transportation (DOT) Vehicle Inspection Form: Similar to the form 296, the DOT Vehicle Inspection Form is utilized to ensure that all parts and systems of a vehicle are in safe, operational condition. Both documents require a thorough check of the vehicle's vital components like brakes, lights, tires, and exhaust systems, emphasizing on-road safety and compliance with regulations.

Commercial Vehicle Safety Alliance (CVSA) Inspection Checklist: This document shares common ground with the form 296 in its purpose to identify safety defects in heavy equipment and vehicles. Both checklists scrutinize aspects such as braking systems, exhaust systems, and the structural integrity of the vehicle, aiming to prevent accidents and ensure the safety of operators and other road users.

Pre-Trip Inspection Checklist: Similar to the section in form 296 dedicated to heavy equipment and transport vehicles, a Pre-Trip Inspection Checklist focuses on evaluating a vehicle before it is used. It encompasses checks for leaks, tire condition, proper functioning of lights and signals, and the presence of emergency equipment, essentially mirroring the intentions of form 296 to promote vehicular reliability and safety.

Osha Heavy Equipment Safety Inspection Checklist: OSHA’s version parallels the form 296 in its commitment to the safety and operational efficiency of heavy machinery and equipment. Both documents require the examination of roll-over protection systems, hydraulic attachments, and structural components to mitigate occupational hazards and safeguard operator well-being.

Fleet Vehicle Condition Report: This document, akin to form 296, is integral in assessing the condition of vehicles within a fleet, focusing on identifying any damages or maintenance needs. Both the Fleet Vehicle Condition Report and form 296 include detailed inspections of the vehicle’s body, cab condition, and cleanliness, ensuring that operational standards are met and maintained.

Dos and Don'ts

When filling out the 296 form for a Vehicle/Heavy Equipment Pre-Use Inspection Checklist, it's crucial to adhere to guidelines ensuring accuracy and thoroughness. This documentation plays a vital role in maintaining safety and compliance with regulations. The following list offers a comprehensive guide on the dos and don'ts during this process:

- Do ensure that all information provided is accurate and complete. This includes details such as the Incident Name/No., Contractor Name, Equipment Type, VIN/Serial No., and License No./State.

- Do carefully check each item listed under the equipment inspection sections, which cover heavy equipment and transport or support vehicles, to verify their condition as either acceptable or not.

- Do use the remarks section (Section V) to describe all unsatisfactory items in detail, identifying them by line number for clarity and action.

- Do verify the operator's and inspector’s signatures and printed names to confirm the inspection's legitimacy and the acknowledgment of liability for the vehicle/equipment's condition.

- Do check for the presence and condition of emergency equipment as required, including fire extinguishers, spare fuses, and reflectors.

- Don't rush through the inspection. Take the necessary time to thoroughly assess each component to ensure it meets safety standards and operational requirements.

- Don't overlook the importance of the "Safety Item—Do not accept until brought into compliance" note. Equipment not meeting safety standards should not be used until compliance is achieved.

- Don't forget to include additional information for operators in the remarks section if applicable, as noted in the instructions.

- Don't neglect to review and adhere to the specific requirements and standards set by the Federal Motor Carrier Safety Administration (FMCSA), U.S. Department of Transportation, and Commercial Vehicle Safety Alliance (CVSA), particularly for transport or support vehicles.

Adhering to these best practices can help ensure that the pre-use inspection process is both efficient and effective, reducing the risk of accidents or non-compliance with regulations. This checklist not only serves as a tool for safety but also as a document of responsibility and accountability for the condition of the equipment prior to its use.

Misconceptions

Understanding the Form 296 for vehicle and heavy equipment inspections is crucial, but there are several misconceptions that can lead to confusion. Let's clear up some of the common misunderstandings:

Misconception 1: The Form 296 Inspection Is Only for Heavy Equipment. While the form does specifically mention "VEHICLE/HEAVY EQUIPMENT PRE-USE INSPECTION CHECKLIST," it also applies to transport and support vehicles. This means checks aren't just for bulldozers or excavators but also include trucks, buses, and vans that support operations.

Misconception 2: A Visual Check Is All That's Needed. The details required on Form 296 go beyond a simple visual overview. For example, the checklist asks for inspection of engine oil levels and condition, battery terminals for corrosion, and checks on brakes and steering components. These require more than just a glance; they need specific checks to ensure safety and compliance.

Misconception 3: Only Mechanical Components Are Inspected. Although the checklist primarily focuses on the mechanical integrity and safety features of the equipment or vehicle, it also stresses cleanliness, the absence of flammable materials, and no invasive species. This broader scope is critical for environmental protection and prevents the spread of potentially harmful plants and substances.

Misconception 4: If It Passes Once, It’s Good Forever. A passed inspection on Form 296 doesn't grant indefinite approval. The condition of equipment and vehicles can change with use and over time, leading to potential safety hazards. Regular inspections are essential, especially considering that certain items, like the "DOT or CVSA inspection" requirement, have specific time frames (last 12 months) mentioned in the form.

Understanding the specifics of Form 296 is essential for operators and inspectors to ensure that vehicles and heavy equipment are safe and compliant for use on projects and job sites. By clearing up these misconceptions, individuals can contribute to safer work environments and avoid potential liabilities or damages arising from equipment failure.

Key takeaways

Filling out and using the Form 296 for pre-use equipment inspections is essential for ensuring safety and compliance in operations involving vehicles and heavy equipment. Here are eight key takeaways from this procedure:

- The checklist emphasizes the importance of verifying the safety features and operational condition of both heavy equipment and transport vehicles before use.

- Items marked with an asterisk (*) are identified as critical safety items. These elements, including the roll-over protection system (ROPS) and functioning seat belts for heavy equipment, must be in compliance before the equipment can be accepted for use.

- The form serves dual purposes: it not only assesses the equipment's readiness but also documents the equipment's condition to manage liability and responsibility effectively.

- Operators and inspectors are required to sign off on the inspection, thereby acknowledging the equipment's condition and the completion of the checklist. This dual signature mechanism underscores the shared responsibility between operators and inspectors for safety compliance.

- Section IV specifically targets transport or support vehicles, indicating a broader application of the form beyond just heavy equipment. Compliance with Department of Transportation (DOT) or Commercial Vehicle Safety Alliance (CVSA) inspections, if applicable, highlights the importance of external safety standards.

- Details such as make/model, equipment type, VIN/serial number, and licensing information are crucial for the identification and tracking of the inspected equipment.

- The checklist includes a section for remarks, enabling inspectors to provide specific details about any item that does not meet the standard requirements. This feature allows for targeted actions to bring equipment into compliance.

- The document acknowledges additional operators by providing space to include information for any individuals operating the equipment, ensuring all users are accounted for and informed about the equipment's condition.

Ultimately, the Form 296 serves as a comprehensive tool for maintaining high safety standards and minimizing liability through thorough pre-use inspections of vehicles and heavy equipment. Adherence to the checklist ensures that operators are aware of their equipment's condition, fostering a safer working environment.

Popular PDF Forms

Pay Net 30 - Apply for a credit application with Net 30 Days terms to help manage and predict your business’s cash flow more effectively.

Mississippi Vehicle Title Application - Whether you're correcting or establishing boat ownership, the Mississippi Certificate of Title form is the vessel to carry you through.