Blank 3853 1 PDF Template

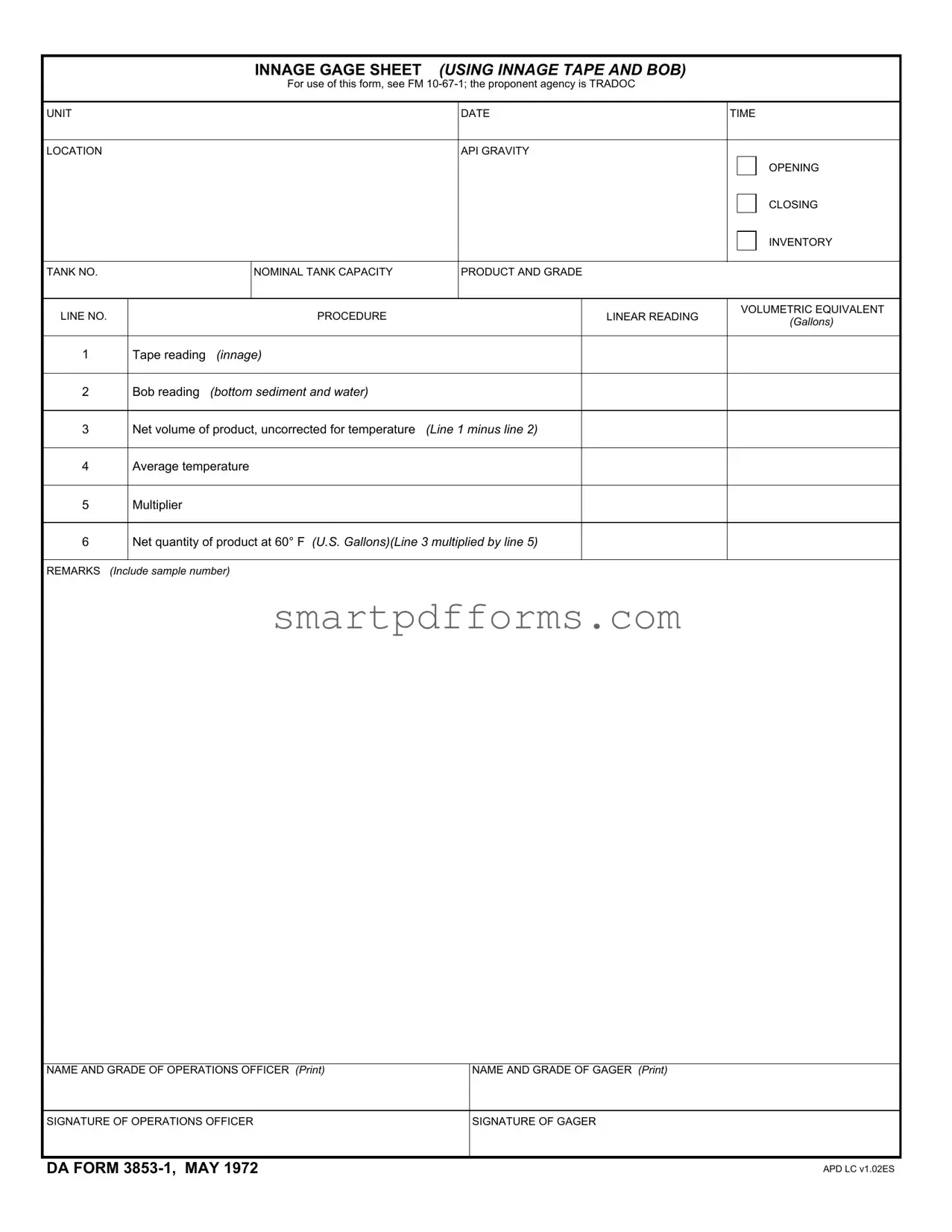

In the intricate domain of fuel management and accounting within military operations, the DA Form 3853-1, known as the Innage Gage Sheet, stands as a crucial document for capturing precise measurements of fuel quantities. Designed for use with an innage tape and bob, this form records the details of fuel inventory within a designated unit location and tank number, ensuring meticulous accounting and oversight. As outlined by the FM 10-67-1, with TRADOC serving as the proponent agency, the form captures essential data points, including date, time, API gravity, and the critical opening and closing inventory figures. Moreover, it delves into an analytical realm by calculating the net quantity of product at standard temperature (60° F), adjusted via a specific multiplier to account for temperature variations. This systematic approach not only aids in maintaining an accurate count of fuel supplies but also contributes significantly to operational efficiency and resource management. Furthermore, this form requires the oversight and signatures of operations officers and gagers, which embeds a layer of accountability and precision in the process. It is a testament to the meticulous planning and resources management vital to the logistical success of military operations.

Preview - 3853 1 Form

INNAGE GAGE SHEET (USING INNAGE TAPE AND BOB)

UNIT

LOCATION

TANK NO.

For use of this form, see FM

DATE |

TIME |

API GRAVITY |

|

OPENING

CLOSING

INVENTORY

NOMINAL TANK CAPACITY |

PRODUCT AND GRADE |

LINE NO. |

PROCEDURE |

LINEAR READING |

VOLUMETRIC EQUIVALENT |

|

(Gallons) |

||||

|

|

|

1Tape reading (innage)

2Bob reading (bottom sediment and water)

3 |

Net volume of product, uncorrected for temperature (Line 1 minus line 2) |

4Average temperature

5

Multiplier

6

Net quantity of product at 60° F (U.S. Gallons)(Line 3 multiplied by line 5)

REMARKS (Include sample number)

NAME AND GRADE OF OPERATIONS OFFICER (Print) |

NAME AND GRADE OF GAGER (Print) |

|

|

SIGNATURE OF OPERATIONS OFFICER |

SIGNATURE OF GAGER |

|

|

DA FORM

APD LC v1.02ES

Form Data

| Fact Name | Description |

|---|---|

| Form Title | INNAGE GAGE SHEET (USING INNAGE TAPE AND BOB) |

| Intended Usage | For measuring and recording tank volumes |

| Regulating Document | For use of this form, see FM 10-67-1 |

| Proponent Agency | TRADOC (Training and Doctrine Command) |

| Form Number and Version | DA FORM 3853-1, MAY 1972, APD LC v1.02ES |

| Main Components on the Form | Product and Grade, Tank No., Date/Time, API Gravity, Tank Capacity, Innage/Bob Readings, Temperature, and Volume Calculations |

| Signature Requirement | Needs signatures of Operations Officer and Gager |

| Special Instructions | Includes space for remarks, such as sample number |

| Governing Laws | N/A - Form follows military regulations, not state-specific laws |

Instructions on Utilizing 3853 1

Filling out the DA Form 3853-1 is a procedural task typically required for documenting specific measurements and data related to the contents of a tank using an innage tape and bob. This form is utilized to ensure accurate record-keeping of the volume, product grade, and other relevant information for substances stored in tanks. It is crucial for maintaining the integrity of inventory management and operational standards. After gathering the necessary data and ensuring accuracy, the steps below guide the completion of this form.

- Under UNIT LOCATION, write the specific location of the tank being measured.

- In the TANK NO. field, enter the identification number of the tank.

- For DATE, provide the current date when the measurements are being taken.

- Record the TIME that the measurement is conducted, ensuring accuracy to the nearest minute if necessary.

- Fill in the API GRAVITY with the appropriate gravity level of the product.

- Specify whether the measurement is an OPENING or CLOSING inventory count.

- Enter the NOMINAL TANK CAPACITY to indicate the total volume the tank is designed to hold.

- Under PRODUCT AND GRADE, identify the type and quality of the product stored.

- Include the LINE NO. if this form is part of a series of measurements.

- For the measurement section, start with a Tape reading (innage) in the first line under LINEAR READING and place its VOLUMETRIC EQUIVALENT (Gallons) in the adjacent column.

- Record the Bob reading (bottom sediment and water) as the second entry under LINEAR READING, along with its volumetric equivalent in gallons.

- Calculate the Net volume of product, uncorrected for temperature (Line 1 minus line 2) and write it in the third entry.

- Enter the Average temperature of the product.

- Provide the Multiplier that accounts for temperature adjustments.

- Finally, calculate the Net quantity of product at 60° F (U.S. Gallons) (Line 3 multiplied by line 5) and record it.

- In the REMARKS section, include any additional information such as sample numbers or observations during the measurement process.

- Write the NAME AND GRADE OF OPERATIONS OFFICER in print.

- Similarly, fill out the NAME AND GRADE OF GAGER in print.

- Both the operations officer and the gager must SIGN in their respective signature lines to validate the measurements and data recorded.

After completing all required fields, review the form to ensure all measurements and information are correct and legible. The completed form should be submitted to the designated supervisory or compliance office for record-keeping, further processing, or analysis. It is crucial to follow any additional instructions specific to your unit or organization regarding the submission and storage of the DA Form 3853-1.

Obtain Answers on 3853 1

What is the purpose of the DA Form 3853-1?

The DA Form 3853-1, also known as the Innage Gage Sheet (using Innage Tape and Bob), is designed for recording measurements related to the inventory of liquid products in storage tanks. Its primary use is to ensure accuracy in the accounting of product volumes within a unit location by factoring in various measurements including the volume of the product, sediment, water, and adjustments for temperature. The form helps in maintaining detailed records for operational efficiency and accountability.

Who is responsible for completing the DA Form 3853-1?

Completion of the DA Form 3853-1 is a joint responsibility. It requires inputs from both the operations officer and the gager. The operations officer, typically of a designated grade or rank, provides oversight and ensures the form is accurately completed, while the gager is directly responsible for taking the precise measurements and recording them on the form. Both individuals must print their names and grades, and sign the form to validate the accuracy of the information recorded.

How is the net quantity of the product calculated using the DA Form 3853-1?

To calculate the net quantity of the product at 60°F, two main steps are involved: measuring the uncorrected volume of the product and then adjusting this value for temperature. First, the volume (gallons) uncorrected for temperature is found by subtracting the bob reading (representing bottom sediment and water) from the tape reading (innage). This result gives the uncorrected net volume of the product. The net volume is then multiplied by a temperature adjustment multiplier to yield the net quantity of the product at 60°F, rendering it a standard for comparison and accounting.

What should be included in the remarks section of the DA Form 3853-1?

The remarks section of the DA Form 3853-1 provides space for additional comments or observations relevant to the innage gage process. This could include, but is not limited to, the sample number of the product being measured, any discrepancies or unusual findings during the measurement process, conditions that might affect the measurement accuracy like weather conditions, and any corrective actions taken. Including such remarks ensures comprehensive documentation of each measurement, aiding in future reference and accountability.

Can the DA Form 3853-1 be used for any type of liquid product?

Yes, the DA Form 3853-1 is versatile and can be used for measuring a variety of liquid products stored in tanks. Its primary function is to document the volume of liquid inventory, regardless of the product type. This includes, but is not limited to, water, fuels, and other chemical liquids of varying grades and densities. The form provides a structured approach to accurately capturing essential data points such as the product and grade, volumetric equivalent, and adjustments for temperature and sediment, making it applicable across different types of liquid products.

Common mistakes

Filling out the DA Form 3853-1 precisely is crucial for accurate record-keeping and accountability in operations involving innage tape and bob measurements. However, errors can occur during its completion. Below are common mistakes made when filling out the DA Form 3853-1:

- Incorrect Date and Time Entries: Failing to properly record the date and time of the measurement leads to discrepancies in records and can affect operational planning and accountability.

- Misidentifying the Tank Number: Each tank has a unique identifier. Incorrectly identifying the tank can result in applying measurements to the wrong inventory.

- Inaccurate API Gravity Records: Misrecording the API gravity affects the calculations related to the product's net quantity, as this measurement adjusts for differences in density.

- Opening and Closing Inventory Mishaps: Not updating these fields accurately reflects poorly on inventory tracking, potentially leading to either surplus or shortage issues.

- Product and Grade Confusion: Mislabeling the product and its grade can cause issues in product quality control and accountability.

- Procedure Errors in Measurement: Incorrectly reporting the linear reading or bob reading impacts the volumetric equivalent calculation, leading to inaccurate inventory reports.

- Temperature Adjustment Oversights: Failing to correctly adjust for temperature when calculating the net quantity of product can significantly alter the perceived inventory level.

- Signature Verification Neglect: The operations officer and gager's signatures are mandatory for verification. Overlooking these can question the authenticity of the form's data.

Avoiding these mistakes ensures the integrity of the data recorded on DA Form 3853-1, which is vital for accurate monitoring and management of resources. Paying close attention to these areas can significantly improve the quality of the information being reported.

Documents used along the form

When managing fuel inventory and accounting in military or complex industrial settings, the DA Form 3853-1, known as the Innage Gage Sheet, is a crucial document. It captures specific data regarding the volume of fuel or product in a storage tank at given times, facilitating precise inventory management. To ensure comprehensive record-keeping and compliance with regulations, several other forms and documents are typically used in conjunction with this form. Below is a brief overview of four such documents.

- DA Form 3643: Daily Issues of Petroleum Products - This document tracks the daily issuance of petroleum products, supporting the reconciliation of remaining inventory levels with the recorded innage and issuance.

- DA Form 3161: Request for Issue or Turn-in - Employed for the requisition or return of items within the supply chain, this form can indicate adjustments in fuel levels that should correlate with inventory changes recorded on the DA Form 3853-1.

- DD Form 1348-1A: Issue Release/Receipt Document - This document serves as an official record for the issue and receipt of military property, including fuel, and can be used to cross-verify the distribution or receiving of fuel products as documented on the Innage Gage Sheet.

- DA Form 1687: Notice of Delegation of Authority - Receipt for Supplies - This form delegates authority to individuals to request and receive supplies on behalf of a unit or department. It establishes the chain of custody for items such as fuel, which is essential for auditing purposes and for validating entries on the Innage Gage Sheet.

Together, these forms create a robust system for tracking, accounting, and managing fuel and other petroleum products. They support accuracy in reporting, accountability among personnel, and efficient operations - crucial aspects of fuel management in any setting. Understanding each document's role and ensuring their correct and timely use is vital for maintaining an effective fuel inventory management system.

Similar forms

The DA Form 3161 (Request for Issue or Turn-in) is similar to the DA Form 3853-1 as both are used within the Department of Defense for managing and recording inventory. The DA Form 3161 specifically focuses on the issuance or return of items, while the DA Form 3853-1 records details related to the inventory levels of liquid products in storage, such as fuel. Both forms require detailed documentation, including the identification of items and the quantities involved.

DD Form 1149 (Requisition and Invoice/Shipping Document) also shares similarities with the DA Form 3853-1 since it is used for documenting the shipment, receipt, and invoicing of supplies and equipment within the military services. Like the DA Form 3853-1, the DD Form 1149 captures product-specific information, quantities, and the condition of items during the shipping process, ensuring accountability and tracking of military assets.

The DA Form 2404 (Equipment Inspection and Maintenance Worksheet) compares to the DA Form 3853-1 in its purpose of recording specific information related to the condition and maintenance of equipment. While the DA Form 3853-1 is used for recording the inventory levels of liquid products, including any discovered discrepancies such as sediment and water content, the DA Form 2404 is utilized for noting equipment faults and serviceability, including measurements and tests performed, thereby ensuring operational readiness and maintenance tracking.

Lastly, the DA Form 5500 (Body Fat Content Worksheet) although vastly different in content, parallels the structure of the DA Form 3853-1 in terms of data collection and calculation. The DA Form 3853-1 involves calculations related to product volumes and adjustments for temperature, similarly, the DA Form 5500 involves calculations pertaining to body fat percentage based on physical measurements. Both forms serve specific, calculation-intensive purposes, driving decisions based on the collected data.

Dos and Don'ts

When completing the DA Form 3853-1, which is used for recording innage measurements of tanks using an innage tape and bob, it's essential to precisely follow instructions to ensure accuracy and compliance. This guidance lays out key dos and don'ts to assist in the process.

DO:

- Verify All Information: Double-check the unit location, tank number, product, and grade, ensuring they accurately represent the tank being measured. Mistakes in these key details can lead to significant discrepancies.

- Ensure Accurate Measurements: When performing tape and bob readings (innage), as well as calculating bottom sediment and water (BS&W), precision is critical. Accurately record these figures to ensure the net volume and net quantity calculations are correct.

- Correctly Calculate Temperatures and Quantities: Pay close attention to the average temperature and use the correct multiplier as these factors directly influence the net quantity of the product at 60° F. Errors in these calculations can significantly impact inventory records and compliance.

- Include Complete Signatures: The form must be signed by both the operations officer and the gager, with their names and grades printed neatly. These signatures are crucial for validating the form’s data.

DON'T:

- Rush Through the Form: Take your time filling out each section to avoid errors. Rushing can lead to oversight of crucial details, particularly in measurements and calculations.

- Skip Fields: Every field in the form serves a purpose. Leaving sections blank can result in incomplete data, which may affect inventory tracking and compliance with regulations.

- Use Incorrect Units: Ensure that measurements are recorded in the appropriate units as specified (e.g., gallons for volumetric equivalents). Using incorrect units can cause significant errors in inventory calculations.

- Forget Remarks: The remarks section is important for noting any inconsistencies, issues, or additional information relevant to the inventory or measurements. Omitting this information can hinder proper understanding and follow-up.

By adhering to these guidelines, individuals can accurately and effectively complete the DA Form 3853-1, thereby ensuring precise tank inventory management and regulatory compliance.

Misconceptions

Understanding the DA Form 3853-1 correctly is crucial for those involved in managing inventory and logistics within certain sectors of the military or any other organization that uses this form. There are several misconceptions surrounding this form which could potentially lead to inaccuracies or inefficiencies in operations. To ensure clarity, let's dispel some common misunderstandings:

- Misconception 1: The form is outdated and no longer in use. Contrary to what some may believe, the DA Form 3853-1, although first issued in May 1972, remains an essential document for inventory management in specific contexts. Updates and versions (as indicated by APD LC v1.02ES) ensure its ongoing relevance.

- Misconception 2: It's only for military use. While it's true that the form was initially designed for military applications, particularly within the Army (as indicated by its proponent agency, TRADOC), its utility extends to any organization managing large volumes of liquid inventory in tanks or similar containers.

- Misconception 3: The form is complicated and difficult to fill out. While detailed, the DA Form 3853-1 is structured logically into specific sections that guide the gager and operations officer through the process of recording and calculating tank contents accurately. Adequate training and practice can simplify its completion significantly.

- Misconception 4: API gravity readings are optional. API gravity is a critical measure indicating the density of the product relative to water. The form specifically requires the recording of API gravity both at the start and end of the inventory period, underscoring the importance of this measurement in calculating the net quantity of product.

- Misconception 5: Temperature corrections are unnecessary. The form demonstrates an understanding of how temperature affects liquid volumes by mandating average temperature recording and its use in volume corrections. This ensures that the product's quantity is accurately reported, accounting for temperature fluctuations.

- Misconception 6: Only the closing inventory matters. The form requires both opening and closing inventory measures, as well as detailed calculations throughout the process. These comprehensive requirements ensure that changes in inventory levels are meticulously tracked and accounted for.

- Misconception 7: The form is solely for tracking petroleum products. While often used for managing petroleum inventories, the DA Form 3853-1 is versatile enough to be applied to any liquid product stored in tanks, provided the necessary measurements and calculations are relevant to the product in question.

Addressing these misconceptions can lead to a better understanding of the DA Form 3853-1's purpose and use. Accurate and efficient use of the form not only supports logistical operations but also ensures compliance with inventory management standards and practices.

Key takeaways

Filling out and using the DA Form 3853-1, also known as the Innage Gage Sheet, is a critical task for accurately measuring the contents of storage tanks, particularly in military or industrial settings. Understanding this form and its correct application ensures precise inventory management and regulatory compliance. Here are five key takeaways about how to properly fill out and utilize this form:

- Understanding the Purpose: The primary goal of the DA Form 3853-1 is to document the volume of liquid in a storage tank using a tape and bob method. This process involves measuring the depth of the liquid (innage) and the depth of any sediment or water (bob reading) at the bottom of the tank to determine the net volume of the product.

- Accurate Documentation: It's essential to record all measurements precisely, including the date and time of measurement, the tank number and location, and the product and grade. This information is crucial for tracking inventory levels and ensuring the quality of the stored product.

- Performing Calculations: After taking the innage and bob readings, subtract the bob reading from the innage reading to find the net volume of the product uncorrected for temperature. Further computations adjust this volume based on the product's average temperature and a multiplier to estimate the net quantity at a standard temperature of 60°F. These calculations are vital for uniformity and comparability across different conditions.

- Completing the Form: Every section of the form must be filled out meticulously, including the remarks section, where additional observations or sample numbers can be noted. Both the operations officer and the gager are required to print their names and grades and sign the form, ensuring accountability and the authenticity of the measurements.

- Comprehension of API Gravity: The API gravity section on the form refers to a measure of how heavy or light a petroleum liquid is compared to water. This information is significant for calculating the volume to weight conversion, which might be necessary for specific operations or reports. Being familiar with how API gravity affects the volume measurements and the subsequent calculations is crucial for accurate and meaningful data.

Filling out the DA Form 3853-1 accurately and methodically is indispensable for effectively managing liquid inventories in storage tanks. Ensuring all measurements and calculations are correct guarantees that the data recorded is reliable and actionable for operational planning and compliance purposes.

Popular PDF Forms

What Is Valic - Provides guidance on Section 457(b) deferred compensation plans for private tax-exempt employers.

Ohio Repossession Laws - Mentions the long-standing reputation of the repossession company since 1967, instilling confidence in the process and the professionals handling the repossession.