Blank 5 Year Fire Sprinkler Inspection PDF Template

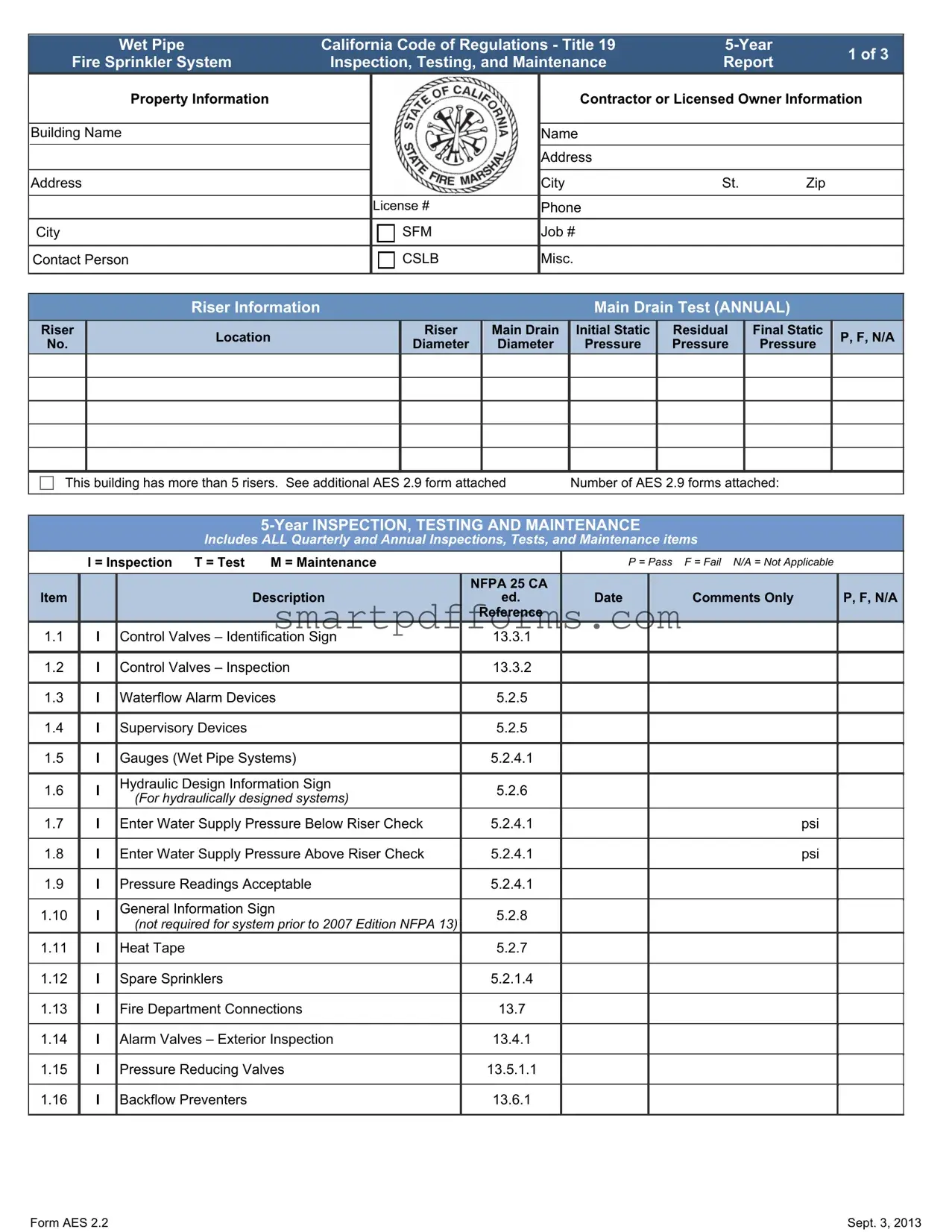

The 5 Year Fire Sprinkler Inspection form serves as a comprehensive document designed to ensure the reliability and proper function of fire sprinkler systems, adhering to the stipulated California Code of Regulations - Title 19. This form, an essential tool for safety and compliance, encompasses a wide array of inspection, testing, and maintenance (ITM) activities laid out over three detail-rich pages. It meticulously records property and contractor information, alongside a spectrum of inspection criteria ranging from control valves to hydraulic design information signs. Integral to the form is the classification of inspection results under categories like "Pass," "Fail," or "Not Applicable," facilitating a clear understanding of the system's status. Furthermore, the document includes an annual ITM section, augmenting its quarterly counterparts, and a segment dedicated to deficiencies and corrective actions. This form not only embodies a commitment to safeguarding premises against fire incidents but also underscores the significance of regular inspections, testing, and maintenance in upholding system effectiveness and compliance with regulatory standards.

Preview - 5 Year Fire Sprinkler Inspection Form

Wet Pipe |

California Code of Regulations - Title 19 |

1 of 3 |

||||

Fire Sprinkler System |

Inspection, Testing, and Maintenance |

Report |

||||

|

||||||

Property Information |

|

|

Contractor or Licensed Owner Information |

|||

|

|

|

|

|

|

|

Building Name |

|

|

Name |

|

|

|

|

|

|

Address |

|

|

|

|

|

|

|

|

|

|

Address |

|

|

City |

St. |

Zip |

|

|

|

|

|

|

|

|

|

|

License # |

Phone |

|

|

|

City |

|

SFM |

Job # |

|

|

|

|

|

|

|

|

|

|

Contact Person |

|

CSLB |

Misc. |

|

|

|

|

|

|

|

|

|

|

|

|

|

Riser Information |

|

|

|

|

|

Main Drain Test (ANNUAL) |

|

||||||

Riser |

|

Location |

Riser |

|

Main Drain |

Initial Static |

|

Residual |

|

Final Static |

P, F, N/A |

|||||

No. |

|

Diameter |

|

Diameter |

Pressure |

|

Pressure |

|

Pressure |

|||||||

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This building has more than 5 risers. See additional AES 2.9 form attached |

Number of AES 2.9 forms attached: |

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|||||||||

|

|

|

Includes ALL Quarterly and Annual Inspections, Tests, and Maintenance items |

|

|

|

||||||||||

|

|

I = Inspection T = Test |

M = Maintenance |

|

|

|

|

|

P = Pass |

F = Fail |

N/A = Not Applicable |

|

||||

Item |

|

|

|

Description |

|

|

NFPA 25 CA |

|

Date |

|

|

Comments Only |

P, F, N/A |

|||

|

|

|

|

|

|

ed. |

|

|

||||||||

|

|

|

|

|

|

|

Reference |

|

|

|

|

|

|

|

|

|

1.1 |

|

I |

Control Valves – Identification Sign |

|

|

13.3.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.2 |

|

I |

Control Valves – Inspection |

|

|

13.3.2 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.3 |

|

I |

Waterflow Alarm Devices |

|

|

5.2.5 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.4 |

|

I |

Supervisory Devices |

|

|

|

5.2.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.5 |

|

I |

Gauges (Wet Pipe Systems) |

|

|

5.2.4.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.6 |

|

I |

Hydraulic Design Information Sign |

|

|

5.2.6 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

(For hydraulically designed systems) |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.7 |

|

I |

Enter Water Supply Pressure Below Riser Check |

|

5.2.4.1 |

|

|

|

|

|

|

psi |

|

|||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.8 |

|

I |

Enter Water Supply Pressure Above Riser Check |

|

5.2.4.1 |

|

|

|

|

|

|

psi |

|

|||

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.9 |

|

I |

Pressure Readings Acceptable |

|

|

5.2.4.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.10 |

|

I |

General Information Sign |

|

|

5.2.8 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

(not required for system prior to 2007 Edition NFPA 13) |

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.11 |

|

I |

Heat Tape |

|

|

|

5.2.7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.12 |

|

I |

Spare Sprinklers |

|

|

|

5.2.1.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.13 |

|

I |

Fire Department Connections |

|

|

13.7 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.14 |

|

I |

Alarm Valves – Exterior Inspection |

|

|

13.4.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1.15 |

|

I |

Pressure Reducing Valves |

|

|

13.5.1.1 |

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.16 |

|

I |

Backflow Preventers |

|

|

|

13.6.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Form AES 2.2 |

Sept. 3, 2013 |

|

|

|

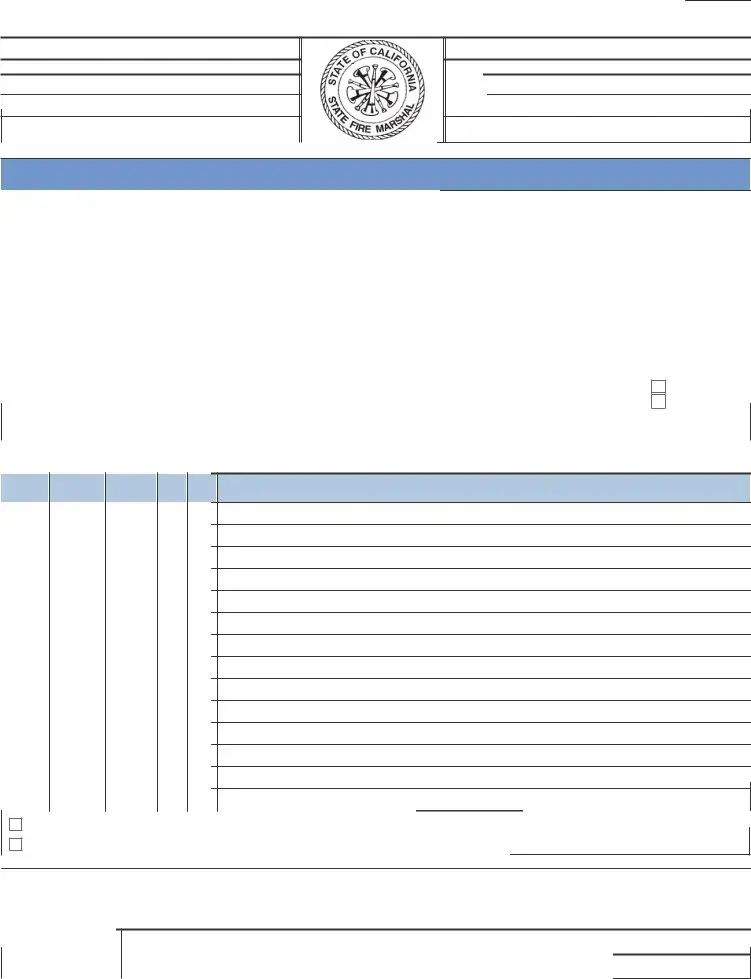

Wet Pipe |

|

California Code of Regulations - Title 19 |

|

5 Year |

2 of 3 |

||||||

|

Fire Sprinkler System |

Inspection, Testing, and Maintenance |

|

Report |

||||||||||

|

|

|

|

|||||||||||

|

|

|

Property Information |

|

|

|

|

Contractor or Licensed Owner Information |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Building Name |

|

|

|

|

Name |

|

|

|

|

|

||||

Address |

|

|

|

|

|

Job # |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

City |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

ANNUAL INSPECTION, TESTING, AND MAINTENANCE |

|

|

||||||||

|

|

|

|

|

Include ALL Quarterly Inspections (See AES 2.1) |

|

|

|||||||

I |

|

= Inspection |

T = Test |

M = Maintenance |

|

|

|

|

P = Pass F = Fail N/A = Not Applicable |

|

|

|||

Item |

|

|

|

Description |

NFPA 25 CA ed. |

|

Date |

|

Comments Only |

P,F,N/A |

||||

|

|

|

Reference |

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.17 |

|

I |

Small Hose Connections - Hose Valve* |

5.1.6, 13.5.2 |

|

|

|

|

|

|

|

|||

|

13.5.5.1 |

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.18 |

|

I |

PRV – Fire Sprinkler Systems |

13.5.1.1 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.19 |

|

I |

Buildings (Freeze Protection) |

4.1.1.1 |

|

|

|

|

Owner’s Responsibility |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.20 |

|

I |

Sprinklers |

|

|

|

5.2.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.21 |

|

I |

Sprinklers - Accessible Concealed Space |

5.2.1.1.6 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.22 |

|

I |

Pipe and Fittings |

|

|

5.2.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.23 |

|

I |

Pipe and Fittings - Accessible Concealed Space |

5.2.2.3 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.24 |

|

I |

Hangers |

|

|

|

5.2.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.25 |

|

I |

Hangers - Accessible Concealed Space |

5.2.3.3 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.26 |

|

I |

Seismic Braces |

|

|

5.2.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

1.27 |

|

I |

Seismic Braces - Accessible Concealed Space |

5.2.3.3 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1.28 |

|

I |

Unsprinklered Areas |

|

|

CFC 901.4 |

|

|

|

|

Yes |

No |

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

2.1 |

|

T |

Field Service Test Required |

5.3.1 |

|

|

|

|

If REQUIRED, Enter 'F' until |

|

|

|||

|

Send Report to Fire Code Official |

|

|

|

|

results are returned from Lab |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

2.2 |

|

T |

Recalled Sprinklers |

|

|

Title 19 |

|

|

|

|

|

|

|

|

|

If not present = Pass; |

If present = Fail |

904.1(c) |

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|||||

2.3 |

|

T |

Water Flow Alarm Devices |

5.3.3 |

|

|

|

|

sec. |

|

|

|||

|

90 secs max. Enter time |

13.2.6 |

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

2.4 |

|

T |

Main Drain Test |

|

|

13.2.5 |

|

|

|

|

|

|

|

|

|

(Enter data on Page 1 of this form) |

13.3.3.4 |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||

2.5 |

|

T |

Control Valve - Position |

|

|

13.3.3.2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.6 |

|

T |

Control Valve – Operation |

|

|

13.3.3.1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.7 |

|

T |

Supervisory Devices |

|

|

13.3.3.5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

2.8 |

|

T |

Backflow Preventer Assemblies |

13.6.2 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.9 |

|

T |

Small Hose Connections* |

|

|

13.5.2.3 |

|

|

|

|

|

|

|

|

|

w/PRV Hose Valves – Partial Flow Test |

13.5.3.3 |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|||||

2.10 |

|

T |

PRV – Fire Sprinkler Systems |

13.5.1.3 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||

2.11 |

|

T |

Pressure Gauges - Calibration |

5.3.2 |

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2.12 |

|

T |

Small Hose Connections* |

|

|

13.5.6.2.2 |

|

|

|

|

|

|

|

|

* Small hose connections are hose valves and optional hose supplied by the fire sprinkler system. They do not include Class I, II, or III standpipe systems.

Form AES 2.2 |

Sept. 3, 2013 |

Wet Pipe |

California Code of Regulations - Title 19 |

5 Year |

3 of 3 |

Fire Sprinkler System |

Inspection, Testing, and Maintenance |

Report |

Property Information

Building Name

Address

City

Contractor or Licensed Owner Information

Name

Job #

ANNUAL INSPECTION, TESTING, AND MAINTENANCE

include ALL Quarterly Inspections (See AES 2.1)

I |

= Inspection |

T = Test |

M = Maintenance |

|

P = Pass |

F = Fail N/A = Not Applicable |

|

||||

Item |

|

|

|

Description |

NFPA 25 CA ed. |

Date |

|

Comments Only |

P,F,N/A |

||

|

|

|

Reference |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

3.1 |

M |

Check Valves - Internal inspection |

13.4.2 |

|

|

|

|

|

|

||

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

3.2 |

M |

Control Valves |

|

13.3.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

3.3 |

M |

FDC - Backflush |

|

14.3.2.3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

14.3.2.4 |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

3.4 |

M |

Internal Pipe Inspection - See Deficiencies and |

14.2 |

|

|

|

|

Yes |

|

||

|

|

|

|

|

|||||||

Comments Section for Results. |

|

|

|

|

No |

|

|||||

|

|

|

|

|

|

|

|

|

|

||

3.5 |

M |

Obstruction Investigation Required. If "Yes", see |

14.3 |

|

|

|

|

|

|

||

|

|

|

|

|

|

||||||

Deficiencies and Comments Section for Results |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|||

3.6 |

M |

System Returned to Service |

4.5.3 |

|

|

|

|

Yes |

|

||

|

|

|

|

|

|||||||

|

|

|

|

No |

|

||||||

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

||||

D = Deficiency C = Comment (Indicate type ) |

|

|

|

|

|

|

|

||||

Item

Date

Riser

D C

Deficiencies and Comments

Indicate all equipment, devices and parts that were repaired or replaced

Check here if additional Deficiencies and Comments are listed on Form AES 9 |

Number attached: |

See Correction Form AES 10 for corrected deficiencies. |

Number attached: |

|

I hereby certify that the fire protection equipment listed above has been fully inspected, tested, and maintained on this date by the company indicated above, in accordance with CCR, Title 19, Sections 901 to 906 and that the equipment is fully operable except as noted in the “Deficiencies and Comments” section of this form.

Print Name

Signature

Date

Form AES 2.2 |

Sept. 3, 2013 |

Form Data

| Fact Name | Detail |

|---|---|

| Governing Legislation | California Code of Regulations - Title 19 |

| Form Purpose | 5-Year Fire Sprinkler System Inspection, Testing, and Maintenance Report |

| Scope of Inspection | Includes ALL Quarterly and Annual Inspections, Tests, and Maintenance items |

| Assessment Criteria | Pass (P), Fail (F), Not Applicable (N/A) |

| Key Areas of Inspection | Control Valves, Waterflow Alarm Devices, Supervisory Devices, Gauges (Wet Pipe Systems) |

| Additional Inspections for Risers | Main Drain Test, Riser Location, and Number of Risers |

| Reporting | Deficiencies and comments indicated for repaired or replaced equipment |

| Special Sections | Includes specific sections for Annual Inspection, Testing, and Maintenance on a separate page |

Instructions on Utilizing 5 Year Fire Sprinkler Inspection

Completing the 5-Year Fire Sprinkler Inspection form is a critical task that ensures fire sprinkler systems are maintained in accordance with safety regulations. This process helps identify any deficiencies that may compromise fire safety within a building. It is essential to provide accurate and thorough information throughout the form to meet compliance standards and enhance the safety of the premises. Here’s how to fill out the form step by step:

- Start with the Property Information section. Enter the building name, address, city, and state including the zip code.

- Move to the Contractor or Licensed Owner Information. Input the name, address, city, and phone number of the contractor or licensed owner. Be sure to include the license number, State Fire Marshal (SFM) job number, Contact person, and the California State License Board (CSLB) number if applicable.

- Complete the Riser Information section by detailing the riser location, number, and diameter. If the building has more than 5 risers, note this and attach additional AES 2.9 form as needed.

- For the Main Drain Test, input the initial static pressure, residual pressure, and final static pressure, marking each result as Passed (P), Failed (F), or Not Applicable (N/A).

- In the section on 5-Year INSPECTION, TESTING, AND MAINTENANCE, mark each item with an Inspection (I), Test (T), or Maintenance (M) designation, and indicate whether it Passed (P), Failed (F), or was Not Applicable (N/A). Include specific NFPA 25 and CA edition references beside each item, and add any relevant comments or dates of inspection/testing/maintenance.

- Proceed to the ANNUAL INSPECTION, TESTING, AND MAINTENANCE sections for both pages 2 and 3 of the form, following the same procedure as in step 5 for each listed item.

- Under Deficiencies and Comments, list any deficiencies noted during the inspection, testing, or maintenance. Indicate whether any corrective action is required and check if additional forms such as the AES 9 or AES 10 are attached.

- Ensure to fill out the Certification section at the bottom of the third page by printing the name of the certified individual, their signature, and the date of the inspection, testing, and maintenance. This certifies that the fire protection equipment has been inspected, tested, and maintained in accordance with the California Code of Regulations, Title 19, Sections 901 to 906.

Remember, the integrity of the fire sprinkler system ensures the safety of the occupants and the property. Taking the time to accurately complete the 5-Year Fire Sprinkler Inspection form is an integral part of maintaining a safe environment.

Obtain Answers on 5 Year Fire Sprinkler Inspection

What is the purpose of the 5-Year Fire Sprinkler System Inspection, Testing, and Maintenance Report?

The 5-Year Fire Sprinkler System Inspection, Testing, and Maintenance Report is designed to ensure that fire sprinkler systems are operable and effective at all times. It is a comprehensive examination of the system’s components, including control valves, waterflow alarm devices, supervisory devices, and more, as per California Code of Regulations - Title 19. The report also checks for deficiencies that could impair the system's operation, ensuring compliance with the safety standards set forth by the National Fire Protection Association (NFPA) and local codes.Who is required to complete this form?

The form must be completed by either a licensed contractor with the appropriate qualifications or the system’s licensed owner. This ensures that the inspection, testing, and maintenance are conducted by individuals with the necessary expertise and knowledge of fire sprinkler systems.What happens if deficiencies are found?

If deficiencies are found during the inspection, they are noted in the "Deficiencies and Comments" section of the form. It is the responsibility of the property owner or the managing entity to address these issues promptly. Additional forms, such as Form AES 9 for listing out the deficiencies in detail and Form AES 10 for documenting the corrective actions taken, may be attached to ensure full disclosure and resolution of all issues.How are inspection results classified in the report?

Inspection results are classified as "Pass," "Fail," or "N/A" (Not Applicable). This classification helps easily identify the areas of the fire sprinkler system that meet the regulatory standards, those that do not, and those for which certain tests or inspections do not apply.What information is included in the Property Information section?

The Property Information section includes details about the property where the fire sprinkler system is installed, such as the building name and address. This information is crucial for accurately documenting where the inspection, testing, and maintenance activities are taking place.What does the "Annual Inspection, Testing, and Maintenance" section entail?

This section covers all the inspections, tests, and maintenance tasks that must be performed annually. It encompasses both the quarterly actions and those specific to the annual review, ensuring that the fire sprinkler system remains in optimal working condition throughout the year.How often does the 5-Year Inspection, Testing, and Maintenance need to be conducted?

As the name suggests, the full inspection, testing, and maintenance process covered by this report is required once every five years. This comprehensive review is above and beyond the annual maintenance routines, targeting to capture any long-term wear and tear or systemic issues that might not be evident in the yearly inspections.

Common mistakes

Filling out the 5 Year Fire Sprinkler Inspection form is a crucial process that helps ensure the safety and compliance of a building's fire sprinkler system. Unfortunately, some common mistakes can hinder this process, impacting the effectiveness of the inspection, testing, and maintenance report. Here are ten mistakes to avoid:

- Not providing complete property information, including the building name, address, city, state, and zip code, can lead to issues with the identification and location of the property in question.

- Failure to detail the contractor or licensed owner information, such as name, address, license number, phone number, and contact person, may result in accountability and communication issues.

- Omitting riser information, including the location, number of risers, and their diameters, affects the accuracy of the inspection report and may overlook crucial areas needing attention.

- Incorrectly reporting main drain test results, including initial, static, and residual pressures, compromises the integrity of the system’s performance evaluation.

- Not indicating whether additional AES 2.9 forms are attached for buildings with more than five risers can lead to incomplete assessment results being documented.

- Overlooking to mark items as Passed (P), Failed (F), or Not Applicable (N/A) under the Inspection, Testing, and Maintenance section can result in non-compliance and a misunderstanding of the system's current status.

- Leaving the comments section blank or not adequately explaining deficiencies or issues noted during the inspection fails to provide a pathway for necessary repairs and actions.

- Failing to check whether the system has been returned to service after maintenance or repair work compromises the building's safety and compliance status.

- Not completing the certification section at the end of the form, including the print name and signature of the person responsible, undermines the legitimacy of the entire document.

- Forgetting to indicate the number of Deficiencies and Comments and Correction Forms (AES 10) attached leaves the inspection report incomplete and may lead to overlooked issues.

In summary, attention to detail and comprehensiveness are key when filling out the 5 Year Fire Sprinkler Inspection form. By avoiding these common mistakes, you can help ensure the safety, compliance, and efficiency of a building's fire sprinkler system.

Documents used along the form

When a property undergoes a 5-Year Fire Sprinkler Inspection, it's crucial to ensure that all aspects of the fire protection system are thoroughly examined and maintained. This inspection is not an isolated process; rather, it involves several documents that work in conjunction to provide a comprehensive overview of the system's condition and compliance with safety standards. Each document plays a vital role in capturing different facets of the system's integrity and functionality. Here's a closer look at these essential documents.

- Quarterly Fire Sprinkler System Maintenance Report: This document complements the 5-Year Fire Sprinkler Inspection form by providing a detailed account of the regular maintenance and inspections carried out on a quarterly basis. Its purpose is to identify and rectify potential issues before they escalate into significant problems, ensuring the system's optimal performance between the more comprehensive 5-year inspections.

- Annual Fire Sprinkler System Inspection Form: Focused on capturing the state of the fire sprinkler system once a year, this form is a critical interim check that highlights any changes or deterioration in the system that may have occurred within the year. It covers aspects such as the condition of sprinkler heads, pipes, and valves to ensure nothing is missed during the time leading up to the detailed 5-year inspection.

- Fire Sprinkler System Correction Form (AES 10): This document is crucial following any inspection, whether quarterly, annually, or every five years. It outlines the specific deficiencies identified during inspections and the corrective actions required or taken. It serves as a follow-up mechanism to ensure compliance and functionality of the fire protection system.

- Fire Sprinkler System Deficiencies and Comments Report: This supplementary form allows for a comprehensive detailing of any deficiencies found during inspections and any comments or observations made by the inspector. It is essential for documenting the condition of the system and for planning any necessary repairs or upgrades.

- Hydraulic Calculation Reports: While not a regular inspection document, hydraulic calculation reports are crucially referenced during the 5-year inspection to verify if the fire sprinkler system meets the flow and pressure requirements as per design specifications. These calculations are fundamental to ensuring the system's effectiveness in actual fire conditions.

Together, these documents form a robust framework for maintaining the safety and efficiency of fire sprinkler systems. Regular and thorough inspections, aided by these forms, help in identifying potential issues early, ensuring that these critical systems function as intended during emergencies. Moreover, they provide property owners and authorities with documented evidence of compliance with safety standards and regulations, offering peace of mind regarding the property’s fire protection measures.

Similar forms

Annual Fire Alarm System Inspection Report: Like the 5 Year Fire Sprinkler Inspection form, this document ensures that all fire alarm systems within a building are thoroughly inspected, tested, and maintained at least once a year. Both documents are critical in verifying that safety protocols comply with state regulations and standards, specifically instructional guidelines like the NFPA (National Fire Protection Association) codes referenced in the sprinkler inspection report. These inspections help identify any deficiencies that need immediate correction to maintain the system's operational integrity and protect the building's occupants.

Quarterly Building Safety Inspection Form: This form focuses on the broader aspects of building safety, including emergency exits, signage, and fire extinguisher checks. Similar to the 5 Year Fire Sprinkler Inspection form, it is a periodic evaluation meant to identify and rectify potential hazards. While it covers a wider range of safety equipment and protocols, both forms serve the essential purpose of preventing emergencies and ensuring that safety mechanisms are in optimal working condition.

Electrical System Inspection Report: Regular inspection of a building's electrical system parallels the fire sprinkler system inspection by emphasizing the prevention of hazards. The Electrical System Inspection Report identifies issues that could lead to electrical fires, outages, or other dangerous situations, ensuring the building's electrical infrastructure operates safely and efficiently. Although it covers a different aspect of building safety, its preventive nature and periodic assessment methodology resemble those of the sprinkler system inspection.

HVAC Inspection and Maintenance Report: While focusing on heating, ventilation, and air conditioning systems, this report shares the goal of the 5 Year Fire Sprinkler Inspection form: to ensure systems are functioning correctly to prevent any risks to building occupants. Regular maintenance and inspection of HVAC systems not only ensure the comfort and safety of residents but also prevent situations that could lead to hazardous conditions, paralleling the motivation behind the sprinkler system's regular inspection.

Backflow Prevention Assembly Test Report: This specific inspection involves checking the prevention assemblies that protect water supplies from contamination due to backflow. Like the fire sprinkler inspection, the backflow prevention test is a specialized examination that requires certified professionals to conduct the tests and maintain the system in compliance with health and safety regulations. Both are integral to maintaining the building's overall safety infrastructure.

Elevator Safety Inspection Certificate: Regular elevator inspections ensure the safety and reliability of a building's elevator systems, protecting users from potential accidents. Similar to the fire sprinkler system inspection, the goal is to adhere to strict safety standards and ensure all components are functioning correctly to avoid hazards. Both inspection types are mandatory and have stringent compliance requirements.

Plumbing System Inspection Report: This document assesses the condition of a building's plumbing infrastructure, examining pipes, fixtures, and sewage lines for leaks or blockages. It shares a preventive maintenance aspect with the fire sprinkler inspection, as both focus on ensuring that critical systems within a building are operational and safe, preventing water damage and other risks.

Building's Structural Integrity Inspection Report: Examining the structural soundness of a building, this inspection ensures that all elements of the construction can withstand normal and extreme conditions. While more focused on the physical integrity of the building rather than specific systems, it is similar in its periodic nature and objective to maintain safety and compliance, creating a safe environment for occupants, paralleling the goals of the fire sprinkler inspection.

Dos and Don'ts

When filling out the 5-Year Fire Sprinkler Inspection form, adhering to specific dos and don'ts is crucial for ensuring the accuracy and compliance of the inspection process. This guidance is essential for property owners, contractors, or licensed owners managing the fire sprinkler systems in their buildings. Here are four dos and four don'ts to keep in mind:

Do:

Ensure all entries on the form are clear and legible. Inaccuracies or illegible information can lead to misunderstandings or a need for re-inspection, which could delay certification.

Verify that every section of the form relevant to your building's fire sprinkler system is completed. This includes annual inspections, testing, and maintenance data, along with any applicable quarterly inspection records.

Include the dates and results for each inspection and test conducted. This information should align with NFPA 25 requirements and any additional local code requirements that may apply.

Provide comprehensive comments on any deficiencies or issues discovered during the inspection, testing, or maintenance visits. Detailing these findings is crucial for future reference and for corrective actions to be taken.

Don't:

Leave any section marked as "N/A" without confirming whether it truly does not apply to your system. For instance, certain components might be deemed non-applicable due to the system's design, but proper verification is essential.

Forget to include additional forms that are referenced in the primary document, such as the AES 2.9 form for buildings with more than five risers. These supplementary forms are integral parts of the inspection record.

Overlook the signature and certification section at the end of the form. An unsigned form lacks validity and cannot be considered a compliant inspection document.

Ignore the follow-up action items listed in the “Deficiencies and Comments” section. Addressing these items promptly ensures your fire sprinkler system remains in optimal operating condition and complies with safety regulations.

Misconceptions

When discussing the 5 Year Fire Sprinkler Inspection form, several misconceptions often arise, stemming from misunderstandings of regulatory requirements, inspection process intricacies, and the implications of inspection outcomes. Here we clarify nine common misconceptions:

- All fire sprinkler systems are subject to the same inspection criteria. In reality, specific criteria and schedules outlined in the form vary based on system type, including wet pipe, dry pipe, and other specialized systems, to accurately address each system’s unique maintenance and operational requirements.

- A "pass" on the form signifies that no maintenance is required. Even when a system passes inspection, ongoing maintenance is crucial to ensure its operability. A pass simply indicates that, at the time of inspection, the system met the required standards.

- Annual inspections are sufficient for compliance. While annual inspections are a critical component of fire sprinkler system maintenance, the 5 Year Fire Sprinkler Inspection includes more comprehensive testing not covered in annual inspections, ensuring a deeper assessment of system integrity.

- The form is only a bureaucratic requirement without practical value. Far from being a mere formality, the inspection process and its documentation on this form play a vital role in identifying potential system failures, thereby preventing possible fire-related casualties and property damage.

- Only professional fire protection services can complete the form. While the form must be filled out by someone knowledgeable about fire sprinkler systems and the relevant codes, in some cases, a licensed owner with sufficient expertise might also complete it, ensuring adherence to regulatory standards.

- If a system fails, it must be completely replaced. A failing grade on an inspection doesn’t necessarily mean a total system replacement is required. Often, specific components can be repaired or replaced to bring the system back to code.

- The inspection form is the same across all states. The example provided is specific to California and adheres to Title 19 regulations. Different states can have varying codes and regulations, making it important to use the correct form and inspection criteria for your location.

- Inspections and maintenance can be deferred without immediate consequences. Delaying inspections or maintenance can lead to system failure in an emergency, posing serious risk to life and property. Furthermore, non-compliance with inspection schedules can result in legal and financial repercussions.

- The inspection form covers all components of fire protection. While comprehensive, the 5 Year Fire Sprinkler Inspection form specifically focuses on sprinkler system components. Other aspects of fire protection, such as fire extinguishers and alarm systems, require separate inspections and documentation.

Understanding these misconceptions is crucial for building owners, facility managers, and fire protection professionals to ensure that fire sprinkler systems are effectively maintained and compliant with the law, thereby safeguarding people and property against fire hazards.

Key takeaways

Filling out and utilizing the 5 Year Fire Sprinkler Inspection form is integral to ensuring the safety and compliance of wet pipe fire sprinkler systems in buildings. This form serves as a comprehensive tool for inspectors, property owners, and contractors, guiding them through the inspection, testing, and maintenance process. Understanding the critical elements of this form can help foster thorough and compliant inspections. Below are five key takeaways that highlight the form's importance and its application:

- The 5 Year Fire Sprinkler Inspection form is structured in a way that covers all quarterly and annual inspection, testing, and maintenance requirements as outlined by the California Code of Regulations - Title 19 and NFPA 25 standards. This ensures a comprehensive review of the fire sprinkler system’s operational integrity over a five-year period.

- Accuracy in completing the property and contractor/licensed owner information sections is crucial for the document’s validity. Proper documentation includes detailed information about the building name, address, the contractor's name, address, license number, phone, and job number. This ensures accountability and traceability in the inspection process.

- The form features a clear distinction between Inspection (I), Test (T), and Maintenance (M) activities, each marked with a binary Pass (P), Fail (F), or Not Applicable (N/A) grading system. This categorization helps in identifying the specific actions taken and the outcomes of those actions, facilitating a straightforward understanding of the system’s status at the time of inspection.

- Inclusion of detailed item descriptions alongside references to relevant sections of the NFPA 25 and California amendments provides a solid framework for inspecting various components of the fire sprinkler system. This includes checks on control valves, waterflow alarm devices, gauges, hydraulic design information signs, and more, thus ensuring each critical component is reviewed against standardized criteria.

- The "Deficiencies and Comments" section is a pivotal part of the form. It allows inspectors to note any abnormalities, malfunctions, or non-compliant elements found during the inspection, testing, and maintenance process. This section plays a critical role in documenting issues that must be addressed to maintain the system’s operational readiness and compliance with fire safety standards.

By adhering to the outlined processes and accurately documenting each inspection, testing, and maintenance activity, property owners and contractors can help ensure that fire sprinkler systems will function as intended in an emergency. This not only aids in protecting property but also in safeguarding lives.

Popular PDF Forms

Editable Frayer Model - A facilitative template for exploring and defining vocabulary within an educational setting, seamlessly integrating into literacy strategies.

What Is a Financial Affidavit for Divorce - This affidavit is critical for child support, alimony, and other financial determinations in family law cases for lower-earning individuals.

Do It Yourself Will Colorado - Addresses the guardianship of minor children, providing peace of mind for parents concerning the future care of their offspring.