Blank Ata 106 PDF Template

In the aviation industry, trust and verification are paramount for the safety and efficiency of operations. The ATA 106 form plays a crucial role in this environment, acting as a certification document that confirms the authenticity and condition of aircraft parts and materials. Drafted to meet the specifications set by the Air Transport Association, the form serves as a bridge of trust between sellers and buyers in the complex ecosystem of aviation parts procurement. It documents essential details such as the seller's information, item description, manufacturer details, quantity, and certification by the last certificated agency. This form ensures that parts sold have met the rigorous standards required by the Federal Aviation Administration (FAA) or have been manufactured according to recognized industry commercial standards. The ATA 106 also includes sections that differentiate between new parts/materials and items that are used, repaired, or overhauled, with mandatory signatures from both parties, attesting to the accuracy and completeness of the information provided. By doing so, it not only upholds the integrity of transactions within the aviation sector but also helps in maintaining the safety standards by ensuring all parts and materials used are properly certified and traced back to their source. Furthermore, the form includes legal reminders about the potential consequences of providing false information, highlighting the seriousness with which these certifications are treated in the context of aviation safety and compliance.

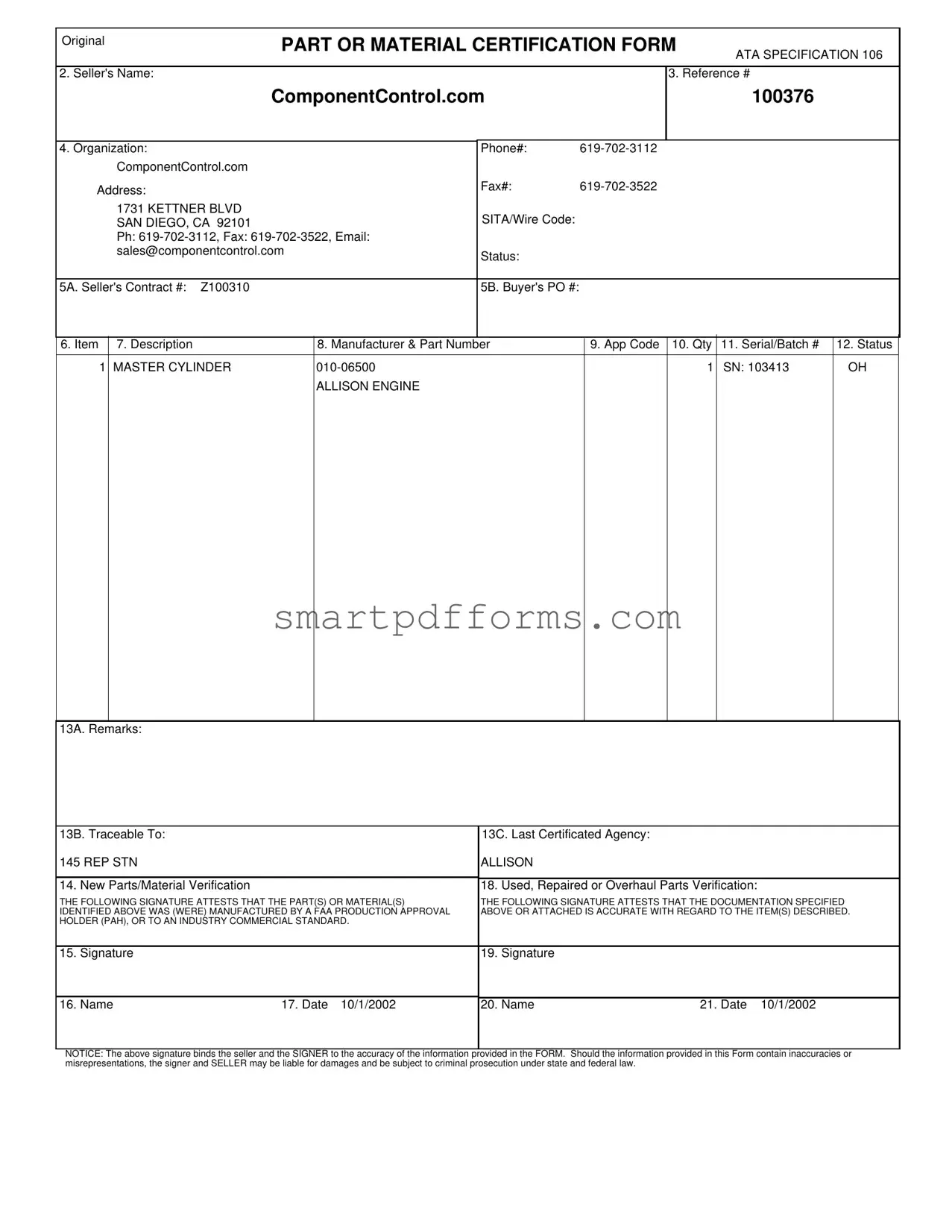

Preview - Ata 106 Form

Original |

PART OR MATERIAL CERTIFICATION FORM |

|

|

ATA SPECIFICATION 106 |

|

|

|

|

|

|

|

2. Seller's Name:

ComponentControl.com

3. Reference #

100376

4.Organization:

ComponentControl.com

Address:

1731 KETTNER BLVD SAN DIEGO, CA 92101

Ph:

Phone#:619-702-3112

Fax#:619-702-3522

SITA/Wire Code:

Status:

5A. Seller's Contract #: Z100310

5B. Buyer's PO #:

6. Item 7. Description |

8. Manufacturer & Part Number |

9. App Code 10. Qty |

11. Serial/Batch # |

12. Status |

|

|

|

|

|

1 MASTER CYLINDER |

1 |

SN: 103413 |

OH |

|

|

ALLISON ENGINE |

|

|

|

13A. |

Remarks: |

|

|

|

|

|

|

|

|

|

|

||

13B. |

Traceable To: |

|

13C. Last Certificated Agency: |

|

||

145 REP STN |

|

ALLISON |

|

|||

|

|

|

|

|

||

14. |

New Parts/Material Verification |

|

18. |

Used, Repaired or Overhaul Parts Verification: |

||

THE FOLLOWING SIGNATURE ATTESTS THAT THE PART(S) OR MATERIAL(S) |

THE FOLLOWING SIGNATURE ATTESTS THAT THE DOCUMENTATION SPECIFIED |

|||||

IDENTIFIED ABOVE WAS (WERE) MANUFACTURED BY A FAA PRODUCTION APPROVAL |

ABOVE OR ATTACHED IS ACCURATE WITH REGARD TO THE ITEM(S) DESCRIBED. |

|||||

HOLDER (PAH), OR TO AN INDUSTRY COMMERCIAL STANDARD. |

|

|

|

|||

|

|

|

|

|

|

|

15. |

Signature |

|

19. |

Signature |

|

|

|

|

|

|

|

|

|

16. |

Name |

17. Date 10/1/2002 |

20. |

Name |

21. Date 10/1/2002 |

|

|

|

|

|

|

|

|

NOTICE: The above signature binds the seller and the SIGNER to the accuracy of the information provided in the FORM. Should the information provided in this Form contain inaccuracies or misrepresentations, the signer and SELLER may be liable for damages and be subject to criminal prosecution under state and federal law.

Form Data

| Fact Name | Description |

|---|---|

| Origin of Form | The ATA 106 form is a certification document used within the aviation industry to certify that parts or materials meet the specified standards. |

| Key Content | This form includes information such as seller's name, reference number, part description, manufacturer, quantity, and the status of parts or materials (new, used, repaired, etc.). |

| Signature Requirement | The form requires signatures to attest the accuracy of the information provided, binding the seller to the authenticity of the documentation. |

| Legal Implications | Inaccuracies or misrepresentations on the form can lead to liability for damages and criminal prosecution under state and federal law. |

| Specific Use | Utilized for parts or materials that are manufactured by an FAA Production Approval Holder (PAH), or to an industry commercial standard, ensuring compliance with aviation standards. |

Instructions on Utilizing Ata 106

Being thorough and accurate when completing forms is essential, especially when it comes to the ATA 106 form. This document plays a crucial role by certifying the status of aviation parts or materials. Whether a part is new, used, repaired, or overhauled, this form provides the necessary certification from the seller to the buyer. It's a critical step in ensuring transparency and trust in the transaction. By following these steps, you can confidently complete the form, ensuring that all information is correct and comprehensive.

- Start by entering the Seller's Name as "ComponentControl.com" in the designated space.

- Fill in the Reference # section with "100376."

- For the Organization field, write "ComponentControl.com" followed by its address, "1731 KETTNER BLVD SAN DIEGO, CA 92101" in the address section.

- Input the Phone# as “619-702-3112” and the Fax# as “619-702-3522.”

- Add the provided Email address, which is "sales@componentcontrol.com", and the SITA/Wire Code in the specified areas.

- Enter the Status: “5A.”

- In the section for the Seller's Contract #, insert "Z100310."

- Fill in the Buyer’s PO # as indicated or required by the context of the transaction.

- Proceed to provide details about the Item such as its name or identification, in this case, "MASTER CYLINDER."

- Include the Description and Manufacturer & Part Number as "010-06500."

- For the App Code, Qty, and Serial/Batch #, enter the appropriate information provided, like “1” for quantity and “SN: 103413” for Serial/Batch #.

- To specify the Status, write “OH” indicating the condition or status of the part.

- In the Remarks section, input any additional information necessary. For example, "ALLISON ENGINE" could be a key remark in some contexts.

- Detail the traceability in the Traceable To field, which in this example is "145 REP STN ALLISON."

- For the Last Certificated Agency, ensure to accurately enter “145 REP STN ALLISON” if it applies to your situation.

- Ensure the New Parts/Material Verification and Used, Repaired or Overhaul Parts Verification sections are completed based on the nature of the part or material.

- Have the form signed and dated in the Signature, Name, and Date sections by the authorized individual to attest to the accuracy of the information provided.

Once completed, this form legally confirms the certification and condition of the aviation part or material in question, binding the seller to the truthfulness of the information provided. It's a safeguard for both parties and ensures compliance with regulations. Always double-check every entry for accuracy before submission to avoid any potential liabilities or legal issues. Completeness and attention to detail are paramount when filling out this form.

Obtain Answers on Ata 106

-

What is an ATA 106 form?

The ATA 106 form, based on Specification 106 from the Air Transport Association, serves as a certification document for parts or materials used in the aviation industry. It provides a record that the specified items were manufactured according to standards set by the Federal Aviation Administration (FAA) or to an accepted industry commercial standard. This form includes details such as the seller’s information, part or material description, manufacturer and part number, quantity, and the certifying signature that attests to the part's compliance.

-

Why is the ATA 106 form important?

The ATA 106 form is crucial for verifying the legitimacy and quality of aviation parts. It helps in maintaining the safety and reliability of aircraft operations by ensuring that all parts and materials used comply with rigorous standards. Moreover, this form facilitates traceability, allowing defective parts to be traced back to their source if a problem arises.

-

What kind of information is included on the ATA 106 form?

The ATA 106 form contains various pieces of information, such as the seller's name and contact details, the item description, manufacturer and part number, the application code, quantity, and serial or batch number. It also includes remarks about the part, its traceability, and the last certificated agency, along with a section for certifications regarding new parts/materials as well as used, repaired, or overhauled parts.

-

Who is responsible for filling out the ATA 106 form?

The seller of the aviation part or material is responsible for providing and filling out the ATA 106 form. It's their duty to ensure that all the information is accurate and reflective of the item being sold. The buyer, on the other hand, should review this form upon receipt to verify the certification and traceability of the parts or materials purchased.

-

How does one verify the accuracy of an ATA 106 form?

Accuracy of an ATA 106 form can be verified through a few steps. First, confirm that the seller’s details match known and reputable suppliers. Next, match the part or material description, manufacturer, and part number with your procurement records. Ensuring the serial number or batch number aligns with your records is also crucial. Finally, for additional assurance, the last certificated agency and traceability information can be cross-referenced with known databases or through direct contact.

-

Are there legal ramifications for inaccuracies found on an ATA 106 form?

Yes, inaccuracies or misrepresentations on an ATA 106 form have serious legal implications. The notice section of the form clearly states that the seller and the signer can be held liable for damages and may face criminal prosecution under state and federal law for providing false information. This underscores the importance of ensuring accuracy and honesty in these certifications.

-

Can an ATA 106 form be used for both new and used parts?

Indeed, the ATA 106 form is designed to certify both new and used parts, including those that have been repaired or overhauled. Separate sections on the form cater to the verification of new parts/materials and the documentation necessary for used, repaired, or overhauled parts, ensuring comprehensive coverage no matter the condition of the item.

-

Is the ATA 106 form recognized internationally?

While the ATA 106 form is based on standards set forth by the Air Transport Association (ATA) and aligns with FAA requirements, its acceptance can vary internationally. However, due to the global nature of the aviation industry and the widespread respect for FAA standards, many countries and international aviation organizations recognize the form or similar documentation for certifying aviation parts and materials.

Common mistakes

Filling out the ATA 106 form, a critical document used for certifying aircraft parts and materials, requires attention to detail. Common mistakes can lead to inaccuracies, potentially causing legal issues or delays in the procurement process. Here are eight mistakes that are often made when completing this form:

Failing to check the accuracy of the seller's name and contact details. It's essential to double-check the information against official documents to ensure completeness and correctness.

Overlooking the reference number. Every form should have a unique reference # for tracking and verification purposes.

Entering incorrect or incomplete manufacturer and part number data. This information must be precise to ensure the correct parts are identified and tracked.

Misunderstanding the status codes. Status codes like 'OH' for overhauled parts must be accurately applied to describe the condition of the item correctly.

Omitting serial or batch numbers when applicable. These numbers are crucial for identifying specific items, especially in case of recalls or quality control issues.

Ignoring the remarks section. Any additional information that could affect the use or installation of the part should be noted here.

Incorrectly verifying new, used, repaired, or overhauled parts. It's crucial to correctly attest the condition and compliance of the parts with FAA standards or other industry standards.

Forgetting to sign or date the form. Unsigned or undated forms are not valid, as the signature attests to the accuracy of the information provided.

In addition, here are some general tips to avoid these common mistakes:

Review all entered information before finalizing the form to catch any errors.

Use official documents as references to ensure all details are accurately transcribed.

Understand the importance of each field in the form to grasp what data is critical and why.

Always double-check the status and condition codes against the latest industry standards.

By avoiding these common mistakes, individuals and companies can ensure that their ATA 106 forms are accurate and compliant, thus facilitating smoother transactions and record-keeping in the aviation industry.

Documents used along the form

When it comes to aerospace parts and materials transactions, the ATA 106 form—Original Part or Material Certification Form—plays a pivotal role. But, this key document often doesn't fly solo. Understanding the other documents that frequently accompany the ATA 106 form helps ensure thorough compliance and traceability in the aeronautics industry. Let's explore some of these critical companions.

- FAA Form 8130-3, Airworthiness Approval Tag: This document certifies that a part or component meets the necessary airworthiness requirements set by the Federal Aviation Administration (FAA). It's a green light for parts to be used in aircraft without causing safety concerns.

- Transfer Documentation: This includes sales agreements, purchase orders, and invoices which record the transfer of ownership of the part or material from seller to buyer. It's the paper trail that proves who owns what.

- Packaging Slip: Essential for logistics, this document lists all parts or materials being shipped, including quantities, part numbers, and descriptions. It ensures the buyer gets exactly what was ordered.

- Manufacturer's Certificate of Conformance: A declaration by the manufacturer that the supplied articles conform to the required specifications and standards. It’s a pledge of quality and compliance from the maker’s bench to the buyer’s hands.

- Maintenance, Repair, and Overhaul (MRO) Documentation: If the part has been repaired or overhauled, documentation detailing the work undertaken, by whom, and the resulting status of the part is vital. This ensures that all modifications meet strict aviation standards.

The dance of documentation in the aviation industry is intricate and vital for ensuring safety, legality, and traceability. The ATA 106 form starts the conga line, but the documents listed above keep the rhythm, ensuring each step in the process is carefully followed and recorded. Building a comprehensive paper trail not only protects parties involved in the immediate transaction but also contributes to the ongoing safety and reliability of the aerospace sector.

Similar forms

The Material Test Report (MTR) shares similarities with the ATA 106 form as both provide assurance about the quality and specification of materials or products. An MTR typically includes detailed information about a material's chemical and physical properties, similarly, the ATA 106 form includes specifications and certifications related to aviation parts, ensuring they meet industry standards.

FAA Form 8130-3, Airworthiness Approval Tag, is another document similar to the ATA 106 form. Both are used in the aviation industry to certify the status and conformity of aviation parts and materials. While the ATA 106 form is utilized to document and trace the lineage of aviation parts, the FAA Form 8130-3 serves as an official record that those parts are approved for return to service following maintenance or manufacture.

The Certificate of Conformance (CoC) is akin to the ATA 106 form in that both certify a product meets the required standards and specifications. A CoC is often used across various industries to ensure that a product complies with specified regulations, whereas the ATA 106 form is specific to the aviation industry, focusing on parts and materials compliance.

ISO 9001 Certification documents, while broader in scope, share the overarching goal of ensuring product and service quality with the ATA 106 form. ISO 9001 certifications demonstrate an organization's commitment to quality management principles including a strong customer focus and continual improvement. Similarly, the ATA 106 form attests to the quality and conformity of aviation parts, underpinning safety and reliability in the aviation sector.

Dos and Don'ts

When filling out the ATA 106 form, there are specific actions you should take to ensure accuracy and compliance. This documentation is crucial for tracking parts and materials in the aviation industry, and it serves as a certification of the item's history, making its accuracy paramount. Below are five essentials to keep in mind for doing it right and avoiding common mistakes.

Do:

- Verify all information before entering it onto the form, especially critical details like part numbers and serial/batch numbers.

- Ensure that the seller's and buyer's details, including names and contact information, are complete and accurate.

- Clearly identify the item's condition - whether it's new, used, repaired, or overhauled - and provide the necessary documentation specified in sections 14 or 18 as applicable.

- Include any remarks or additional information in section 13A that might be relevant for the next buyer or for regulatory compliance.

- Review the completed form thoroughly before signing to attest to the accuracy of the information provided.

Don't:

- Leave any fields blank. If a section does not apply, indicate with "N/A" or "not applicable" to show that it was intentionally left empty.

- Guess or approximate information. If you are unsure about specific details, it's better to verify first rather than risk inaccuracies.

- Overlook the importance of the document’s traceability information (section 13B and 13C), as this is critical for the part's history and authenticity.

- Forget to provide updated contact information in case there are questions or the need for clarification about the form.

- Rush through the process. Taking the time to double-check entries can prevent mistakes that might cause legal or compliance issues later.

The ATA 106 form is a key document in maintaining the integrity of parts and materials in the aviation industry. Handling it with the utmost care and attention to detail ensures compliance and contributes to the safety and reliability of aviation operations. Always approach this task with diligence and accuracy in mind.

Misconceptions

Understanding the ATA 106 form is critical for individuals involved in the aviation industry, particularly in the areas of parts procurement, maintenance, and repair. However, misconceptions about its purpose and contents can lead to confusion. Below are five common misconceptions about the ATA 106 form and the facts that dispel them.

- Misconception #1: The ATA 106 form is only for new parts.

People often think that the ATA 106 form is exclusively used for certifying new parts. However, this form also accommodates the certification of used, repaired, or overhauled parts, as indicated by the verification sections concerning the condition of the parts. This distinction ensures that all parts, regardless of their new or used status, undergo rigorous documentation to maintain safety and compliance.

- Misconception #2: The form is a legal document binding the seller and buyer in a sales contract.

While the ATA 106 form is a crucial document for part certification, it is not, in and of itself, a sales contract between the seller and the buyer. The notice section clarifies that the signer and seller are bound to the accuracy of the provided information, focusing on the certification of the part or material's authenticity and compliance rather than establishing a sales agreement.

- Misconception #3: Any part listed on the ATA 106 form is automatically FAA approved.

The certification on the ATA 106 form states that the parts were manufactured by a FAA Production Approval Holder (PAH) or to an industry commercial standard. This does not mean every part listed has direct FAA approval. The form serves as a certification of adherence to standards, not as direct FAA endorsement of each part's individual compliance or suitability.

- Misconception #4: The form serves as a comprehensive history report for a part.

Although the ATA 106 form includes sections for tracing a part back to its last certificated agency and remarks concerning its condition or history, it does not provide a complete history of the part. The form focuses on certifying the current status and compliance of the part rather than detailing its full lineage or operational history.

- Misconception #5: Completion of the ATA 106 form is voluntary for sellers.

Some may believe that filling out and providing an ATA 106 form is optional or at the discretion of the seller. In reality, the provision of this form is a critical step in ensuring transparency and adherence to industry standards for aviation parts. The form is not merely a formality but a necessary document for certifying the status and compliance of aviation parts and materials, helping to maintain safety and regulatory compliance in the aviation industry.

Dispelling these misconceptions is vital for all stakeholders in the aviation industry to understand the importance of the ATA 106 form in maintaining safety, compliance, and trust in aviation operations.

Key takeaways

Understanding the ATA 106 Form is crucial for ensuring compliance and accuracy in aerospace part transactions. Here are key takeaways:

- The ATA 106 form serves as a certificate for aircraft parts or materials, indicating conformance to FAA standards or industry commercial standards.

- It is essential to provide the seller's name and contact information, including phone and fax numbers, to facilitate clear communication.

- Reference and contract numbers from both seller and buyer, as specified in sections 5A and 5B, are critical for tracking and validating transactions.

- The form requires detailed information about the item, including description, manufacturer, part number, and quantity, ensuring the precise identification of parts or materials.

- Serial or batch numbers must be clearly stated for parts tracking and verification of individual components or material batches.

- For parts that are new, repaired, or overhauled, the form includes sections for verification signatures, binding the seller to the accuracy of the provided information.

- Any misrepresentations or inaccuracies on the form can subject the seller and signer to legal repercussions, highlighting the importance of careful and accurate form completion.

Accuracy and diligence in filling out the ATA 106 form not only comply with regulations but also facilitate trust and reliability in aerospace parts transactions.

Popular PDF Forms

Jtwros Meaning - A crucial legal form for joint property owners, used to certify the death of a co-owner and initiate the reassignment of ownership.

How to Avoid Paying Sales Tax on a Used Car in California - Filling out the BOE 448 form involves certifying under penalty of perjury, highlighting the seriousness of the information provided regarding out-of-state vehicle delivery.