Blank Backflow Test Report PDF Template

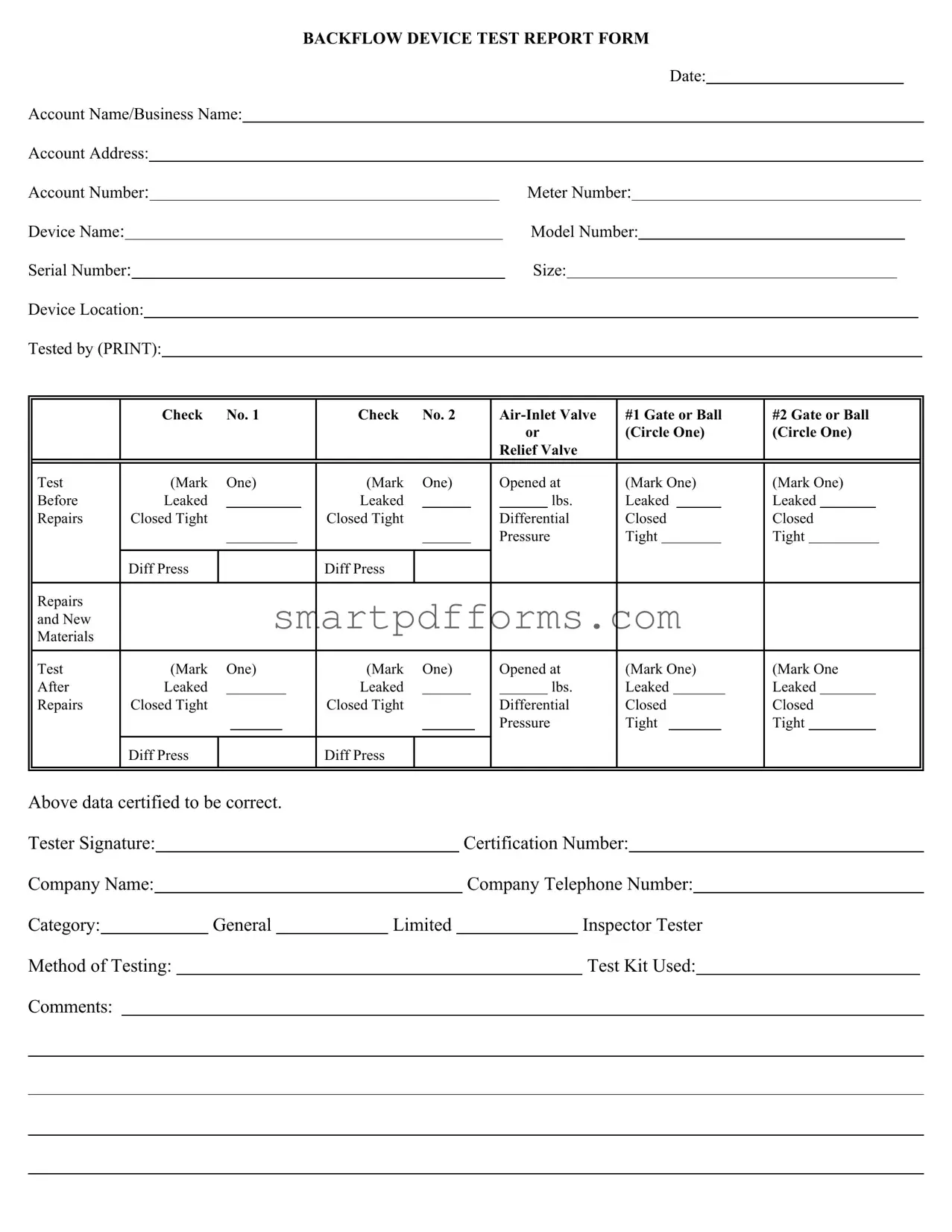

Ensuring the safety and purity of water within any building, whether a home or a business, is paramount, which is where the Backflow Device Test Report Form plays a crucial role. This comprehensive document serves as a vital tool for capturing essential data regarding the testing of backflow prevention devices. These devices are critical in preventing contaminated water from flowing back into the clean water supply. The form meticulously records a variety of important information, including the date of the test, details of the account and meter, specifics about the device including name, model, and serial number, and its location. The process of testing is detailed through checks on air-inlet valves, gate or ball valves, relief valves, and includes whether any leaks were detected before and after repairs were made. It emphasizes the conditions under which the device operates, noting pressures and differential pressures. The tester's credentials – including their printed name, signature, certification number, and contact information – are also part of this crucial document. This form not only provides a record for property owners and local authorities but is also essential for maintaining public health standards by ensuring the effective operation of backflow preventers.

Preview - Backflow Test Report Form

BACKFLOW DEVICE TEST REPORT FORM

Date:

Account Name/Business Name:

Account Address:

Account Number: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Meter Number: |

|

|

|

|

|

|

|

|

||||||||||||||||||||||

Device Name: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Model Number: |

|

|

|

|

|

|

|

|

||||||||||||||||

Serial Number: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Size: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Device Location: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

Tested by (PRINT): |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CHECK |

|

|

NO. 1 |

CHECK |

|

NO. 2 |

|

|

|

|

#1 GATE OR BALL |

#2 GATE OR BALL |

|||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OR |

|

|

(CIRCLE ONE) |

(CIRCLE ONE) |

||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

RELIEF VALVE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test |

|

|

|

|

|

|

(Mark |

|

|

One) |

(Mark |

|

One) |

|

|

|

|

Opened at |

|

|

(Mark One) |

(Mark One) |

|||||||||||||||||||||||||||||

Before |

|

|

|

|

|

|

Leaked |

|

|

|

|

|

|

|

|

|

Leaked |

|

|

|

|

|

|

|

|

|

lbs. |

|

|

Leaked |

|

|

Leaked |

|

|

||||||||||||||||

Repairs |

|

Closed Tight |

|

|

|

|

|

|

|

|

|

Closed Tight |

|

|

|

|

|

|

Differential |

|

|

Closed |

Closed |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure |

|

|

Tight |

Tight |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diff Press |

|

|

|

|

|

|

|

|

|

Diff Press |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Repairs |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and New |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Materials |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test |

|

|

|

|

|

|

(Mark |

|

|

One) |

(Mark |

|

One) |

|

|

|

|

Opened at |

|

|

(Mark One) |

(Mark One |

|||||||||||||||||||||||||||||

After |

|

|

|

|

|

|

Leaked |

|

|

|

|

|

|

|

|

|

Leaked |

|

|

|

|

|

|

|

|

|

lbs. |

|

|

Leaked |

|

|

Leaked |

|

|

||||||||||||||||

Repairs |

|

Closed Tight |

|

|

|

|

|

|

|

|

|

Closed Tight |

|

|

|

|

|

|

Differential |

|

|

Closed |

Closed |

||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Pressure |

|

|

Tight |

Tight |

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diff Press |

|

|

|

|

|

|

|

|

|

Diff Press |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Above data certified to be correct. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||||

Tester Signature: |

|

|

|

|

|

|

|

|

|

|

|

|

|

Certification Number: |

|

|

|

|

|

|

|

||||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||||||

Company Name: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Company Telephone Number: |

|

|

|

|

|

|

|

|||||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||||||

Category: |

|

|

|

|

|

|

|

|

General |

|

|

Limited |

|

|

|

|

|

|

|

|

|

Inspector Tester |

|

|

|

|

|

|

|

||||||||||||||||||||||

Method of Testing: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Test Kit Used: |

|

|

|

|

|

|

|

||||||||||||||||||||

Comments: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Form Data

| Fact Number | Description |

|---|---|

| 1 | The Backflow Device Test Report Form is utilized to document the testing and performance of backflow prevention devices. |

| 2 | It captures detailed information including date, account name/business name, and specific device details such as model number and serial number. |

| 3 | Detailed test procedures, including checks for air-inlet valve, gate or ball valve functionality, and relief valve performance, are outlined by marking applicable options. |

| 4 | The form includes sections for documenting the condition of the device before and after repairs, indicating leaks, tightness, and pressure differentials. |

| 5 | Testers are required to certify the accuracy of the information provided by signing the form and providing their certification number. |

| 6 | It also records the company performing the test, including the company name and telephone number, along with the tester's category and the method of testing used. |

| 7 | Additional comments can be included to provide context or details not captured by the standard form fields. |

| 8 | For states with specific regulations, the form must align with the governing laws related to backflow prevention and testing protocols. |

Instructions on Utilizing Backflow Test Report

Once a backflow prevention device has been tested, it's essential to accurately fill out a Backflow Test Report form. This document is vital for ensuring the safety of a water system, proving that the device is functioning correctly and preventing contaminated water from flowing back into clean water supplies. The following steps will guide you through completing this form properly.

- Begin by noting the Date of the test at the top of the form.

- Fill in the Account Name/Business Name to identify the owner of the device.

- Provide the complete Account Address where the backflow device is located.

- Enter the Account Number associated with this specific backflow device.

- Record the Meter Number to link the test to the water meter in question.

- Specify the Device Name, Model Number, and Serial Number for precise identification.

- Include the Size of the device and its exact Device Location.

- In the section marked "Tested by (PRINT)," clearly print the name of the individual conducting the test.

- For both CHECK NO. 1 and CHECK NO. 2, circle the appropriate options regarding the state of the air-inlet valve, gate or ball valves, and relief valve before and after any repairs. Additionally, indicate if the valves were "Leaked" or "Closed Tight" and record the differential pressure readings.

- Sign the report in the space provided under "Above data certified to be correct" to verify the accuracy of the information provided.

- Include the tester's Certification Number, ensuring the legitimacy of the test.

- Fill out the Company Name and Company Telephone Number for potential follow-up or verification.

- Indicate the category of tester, whether General, Limited, or Inspector Tester.

- Specify the Method of Testing and the Test Kit Used to conduct the test.

- In the comments section, add any additional observations or necessary information regarding the test or the device's condition.

Upon completing the form, review all entries for accuracy before submission. This step ensures that all relevant data has been accurately and thoroughly documented, supporting the continued safety and compliance of water systems against backflow incidents.

Obtain Answers on Backflow Test Report

-

What is a Backflow Test Report form?

A Backflow Test Report form is a document used by certified professionals to record the results of tests performed on backflow prevention devices. These devices prevent contaminated water from flowing back into clean water supplies. The form includes information such as the date of the test, account details, device specifics (name, model, serial number, size, and location), the tester's information, test results for specific checks, and any repairs or new materials used.

-

Why is it important to complete a Backflow Test Report form?

Completing a Backflow Test Report form is crucial for ensuring public health and safety. By documenting the performance and condition of backflow devices, the report helps in maintaining the integrity of a potable water system. It serves as a record of compliance with local and federal regulations aimed at preventing water contamination.

-

Who is authorized to perform the tests and fill out the Backflow Test Report form?

Only certified testers, who are licensed by a recognized authority and have undergone specific training in testing and maintenance of backflow prevention devices, are authorized to perform the tests and complete the report. These professionals may carry different titles, such as General Tester, Limited Tester, Inspector, or Tester, depending on their certification and the scope of their authority.

-

What details must be provided in the Backflow Test Report form?

- Date of the test

- Account Name/Business Name and Address

- Account and Meter Numbers

- Device Name, Model Number, Serial Number, Size, and Location

- Tester's printed name, signature, certification number, company name, and telephone number

- Results for tests like Air-Inlet Valve, Gate or Ball Valve, and Relief Valve, including conditions pre and post any repairs

- Method of Testing and Test Kit Used

- Any additional comments related to the test or device condition

-

How often should a Backflow Test Report be submitted?

The frequency at which a Backflow Test Report needs to be submitted depends on local regulations and the type of the premises where the backflow device is installed. Typically, testing is required annually, but some areas or specific types of facilities, such as hospitals or manufacturing plants, may require more frequent testing.

-

Where should the Backflow Test Report form be submitted?

The completed Backflow Test Report form should be submitted to the local water authority or the regulatory body responsible for water safety in the area. Some jurisdictions may allow or require electronic submission, while others may require a physical copy to be mailed or delivered in person.

-

What happens if a backflow prevention device fails its test?

If a device fails its test, it must be repaired or replaced immediately to ensure the safety of the water supply. The specific steps and timeline for repairs or replacement, as well as any re-testing requirements, are typically outlined by local regulations. A follow-up Backflow Test Report documenting the corrective action and the results of the re-test must be submitted to confirm that the device is now functioning properly.

Common mistakes

Filling out a Backflow Test Report form might seem straightforward, but errors can creep in easily if you're not careful. Here's a guide to the most common mistakes people make, so you can avoid them:

- Not checking the date: Forgetting to fill in or incorrectly entering the date can cause confusion and delays.

- Incorrect or incomplete account information: Mixing up the Account Name/Business Name, Account Address, Account Number, or Meter Number can lead to misidentification and processing errors.

- Skip details about the device: Missing or incorrect details about the Device Name, Model Number, Serial Number, or Size can compromise the accuracy of the report.

- Omitting device location: Not specifying the Device Location clearly can lead to misunderstandings about which device was tested.

- Illegible tester information: If the "Tested by" section is unreadable, it might be impossible to verify the test or contact the tester for follow-up.

- Incorrect test results: Misreporting findings for the check valves, relief valve, and differential pressure can invalidate the test.

- Failure to circle choice where indicated: Not circling the appropriate options under "Check No. 1" and "Check No. 2" sections may lead to inaccurate interpretations of the test outcomes.

- Incomplete certification details: Neglecting to include the Tester Signature, Certification Number, Company Name, or Company Telephone Number can question the report's validity.

Additionally, here are some general tips to ensure the accuracy and completeness of the report:

- Double-check all entered information for accuracy before submitting.

- Make sure all required fields are complete and legible.

- Review the method of testing and the test kit used for consistency and correctness.

- Use the comments section to provide any relevant details or observations that might be helpful in interpreting the test results.

By keeping an eye out for these common mistakes and following these tips, you can help ensure your Backflow Test Report form is filled out correctly and efficiently, supporting the overall goal of maintaining a safe and compliant water system.

Documents used along the form

When it comes to ensuring the safety and compliance of water systems, the Backflow Test Report form plays a crucial role. However, it often doesn’t stand alone. To fully grasp the context and ensure regulatory compliance, a suite of additional documents and forms may also be necessary. These documents each serve a unique purpose, from establishing the identity of the tester to detailing the specifics of the water system in question.

- Certification of Backflow Assembly Tester: This document certifies the qualifications of the individual performing the backflow test, ensuring they meet local and state requirements.

- Customer Consent Form: Obtained from the property owner or responsible person, this form grants the tester permission to access the property and perform the backflow test.

- Water System Schematic: This detailed diagram provides an overview of the property’s water system layout, illustrating all connections, backflow prevention devices, and potential cross-connection risks.

- Device Installation Form: Documents the initial installation details of the backflow prevention device, including the specific model, location, and date of installation.

- Repair and Maintenance Log: A historical record of any repairs, replacements, or maintenance activities performed on the backflow prevention device, vital for diagnosing recurring issues.

- Local Water Authority Regulations: A document or booklet detailing the specific backflow prevention regulations and requirements set forth by the local water authority, ensuring compliance with regional standards.

- Incident Report Form: Used in the event of a backflow incident to document what occurred, the suspected cause, and the steps taken to resolve the issue and prevent future occurrences.

- Backflow Device Manufacturer’s Manual: Contains detailed specifications, operation instructions, and maintenance guidelines for the backflow prevention device, essential for proper testing and repair.

Together, these documents create a comprehensive portfolio that supports the backflow testing process. They ensure that tests are carried out by qualified individuals, according to the correct procedures, and in compliance with local regulations. This holistic approach not only helps in maintaining public health standards by protecting water supplies from contamination but also aids property owners and businesses in navigating the complexities of water system management.

Similar forms

Vehicle Inspection Report: Similar to the Backflow Test Report Form, a Vehicle Inspection Report documents the condition and safety of a vehicle at a specific point in time. Both forms include sections for identification (e.g., serial number or vehicle identification number), inspection results with checkboxes or spaces for detailing issues found, and certification by the individual conducting the inspection. They are critical for ensuring compliance with safety standards.

Home Inspection Report: This form shares similarities in structure and function with the Backflow Test Report Form by detailing the condition of a property's key components. Both require the inspector to check off various items as they assess each component, marking them as satisfactory, in need of repair, or identifying potential issues. Signatures and certification details at the end of both forms verify the accuracy of the report.

Electrical Safety Inspection Checklist: Used to ensure electrical systems and components meet safety standards, this checklist parallels the Backflow Test Report Form. Both documents list specific items to be inspected (e.g., device name/model for backflow, wiring/equipment for electrical), criteria for passing the inspection, and a section for comments on required actions or anomalies found. Completeness and reliability are certified by the inspector's signature.

Environmental Compliance Audit: Though focused on environmental regulations, this audit form is akin to the Backflow Test Report Form in its comprehensive review of compliance with specified standards. It typically includes the auditor’s observations, test results, and recommendations for improvement or repair—similar to the "Comments" section in the Backflow Test Report Form. Both forms play a crucial role in maintaining safety and regulatory compliance, and are finalized with a certification process.

Dos and Don'ts

When completing the Backflow Test Report form, it is essential to ensure accuracy and compliance to avoid incorrect data submission that could result in potential water safety hazards or non-compliance fees. Here is a compiled list of dos and don'ts to consider:

-

Do:

- Verify all provided information, such as account name, address, and numbers for the account, meter, device model, and serial, ensuring they are accurate and match the tested backflow device.

- Clearly indicate the specific device name along with its size and exact location to prevent any ambiguity about which device was tested.

- Print the name of the person conducting the test to ensure legibility for anyone reviewing the form.

- Complete all sections with the required test results, including CHECK NO. 1 and CHECK NO. 2, without leaving any fields blank.

- Use a tick or a clear mark to indicate selections for checkboxes and circle the chosen options where multiple choices are presented.

- Include the differential pressure readings accurately, as this is crucial for assessing the device's performance.

- Note any repairs and new materials used during or after the test in the designated comment section to provide a full record of work done on the device.

- Provide the tester's certification number and contact information for the company they represent, enhancing the report's credibility and allowing for follow-up if required.

- Ensure the tester's signature is included at the end of the report to authenticate it.

- Review the entire form before submission to ensure all data is correct and complete, minimizing any delays in processing.

-

Don't:

- Leave any field blank; if a section does not apply, mark it as "N/A" to indicate that it was considered but not applicable.

- Guess on measurements or details about the backflow device; inaccuracies can lead to incorrect assessments of risk and device functionality.

- Rush through the form, which can lead to errors or omissions that may compromise water safety or compliance.

- Use unclear handwriting that could make it hard for others to understand the report, risking misinterpretations.

- Forget to specify the method of testing and the test kit used, as these details validate the testing process.

- Omit comments on unexpected observations or recommendations for further action, which are valuable for ongoing water safety management.

- Alter any previously submitted reports without proper documentation and resubmission, to maintain the integrity of the testing process.

- Ignore the need for a witness or additional verifier if required by local regulations or standard procedures for such tests.

- Submit the form without ensuring that all corrective actions noted have been taken and verified, which is necessary for compliance.

- Disregard local or industry-specific guidelines that may add additional requirements or steps to the backflow test reporting process.

Misconceptions

When navigating through the requirements and implications of the Backflow Test Report form, several misconceptions commonly arise. These misunderstandings can lead to incorrect assumptions about the testing process, the form's importance, and the responsibilities of property owners and testers. Here, we address four of the most prevalent misconceptions to clarify these aspects.

- Only properties with major plumbing systems require backflow testing.

This misconception assumes that only large commercial properties or those with complex plumbing systems are subject to backflow testing. In reality, many municipalities require backflow testing for a wide range of properties, including residential homes. This requirement is based on the potential risk to the public water supply, not just the complexity or size of the property's plumbing system.

- Filling out the Backflow Test Report form is the sole responsibility of the tester.

While it is true that the certified tester is responsible for conducting the test and recording the results, property owners play a crucial role in this process as well. Property owners are responsible for ensuring that the testing is completed by a certified professional and for maintaining the records of such tests. They must also ensure that any necessary repairs highlighted by the test are carried out to maintain the integrity of the backflow prevention device.

- The form requires technical knowledge beyond the average property owner's understanding.

Though the Backflow Test Report form contains technical details regarding the backflow device and the test results, it is designed to be understandable. Key sections such as the device’s location, the tester’s information, and the test outcomes are outlined in a manner that can be comprehended with a basic understanding of backflow devices. The importance lies in ensuring the correctness of the data entered rather than having extensive technical knowledge.

- Once submitted, the Backflow Test Report form does not need to be reviewed or updated.

This belief underestimates the form's role in ongoing water safety. The test report provides a snapshot of the device's performance at the time of testing. However, changes to the plumbing system, the installation of new devices, or repairs to the existing backflow preventer can necessitate reevaluation and resubmission of the form. Regularly scheduled tests ensure the device continues to protect the water supply from contamination effectively.

Understanding these misconceptions allows property owners and testers to approach backflow prevention with the seriousness it deserves. It emphasizes the collaborative effort required between testers, property owners, and regulatory agencies to protect public health and the environment.

Key takeaways

Filling out and using the Backflow Test Report form is a critical process that requires attention to detail and accuracy. Here are some key takeaways to keep in mind:

- Ensure you record the date of the test accurately, as this establishes the timeline for compliance and maintenance records.

- Clearly and accurately fill in all identification information, including Account Name/Business Name, Account Address, Account Number, Meter Number, Device Name, Model Number, Serial Number, and Size, to ensure the report is properly associated with the correct backflow prevention device.

- Specify the device location with as much detail as possible to facilitate future inspections, tests, and maintenance activities.

- It’s important for the person conducting the test ("Tested by") to print their name legibly to maintain the accountability and traceability of the test results.

- The form requires meticulous recording of test results for different checks including the condition of the AIR-INLET VALVE, GATE OR BALL valves, and the RELIEF VALVE, both before and after any necessary repairs. Accurate reporting here is vital for assessing the device’s performance and safety.

- Indicating whether leaks were found, the pressure at which valves opened or closed, and noting differential pressure readings are all critical for evaluating the device's functional integrity. Misreporting in these sections can lead to improper assessment of the device’s condition.

- Documenting repairs and new materials used is essential for maintaining a history of the device's maintenance. This information is crucial for understanding the lifecycle and reliability of the backflow prevention device.

- The tester’s signature, certification number, company name, and contact information are mandatory to validate the report. Furthermore, specifying the method of testing and the test kit used provides additional validation of the test’s authenticity and adherence to standards.

Completing the Backflow Test Report form with diligence and precision is not just about regulatory compliance; it's also about ensuring the safety of water systems. This document serves as an official record of the device's condition at the time of testing, and its accuracy has direct implications on public health and safety. Therefore, it is incumbent upon those tasked with these responsibilities to approach them with the utmost seriousness and professionalism.

Popular PDF Forms

How Much Does It Cost to Change Your Last Name in Colorado - The JDF 205 form aligns with the principle that financial barriers should not impede access to legal rights and protections.

What Is a Physical for a Job - The form prompts review of the individual's job title and duties, linking health assessment directly to job-specific requirements.

Form It38 - Detail any liabilities, costs, or expenses that were properly paid out from the benefit.