Blank Cf 1R Alt Hvac PDF Template

The CF-1R-ALT-HVAC form is an essential document designed to ensure that residential HVAC alterations in California's Climate Zones 10 to 15 comply with the 2008 Building Energy Efficiency Standards. It underscores the critical collaboration between the Contractors State License Board and local building departments in enforcing regulations and highlights the severe repercussions for contractors who willfully disregard building laws. The form mandates that permits are obtained for various HVAC projects, setting forth requirements such as minimum heating equipment AFUE and central air conditioners' SEER ratings, alongside duct insulation and thermostat requirements. Importantly, it outlines when HERS verification is needed, delineating the necessary forms and tests for different HVAC alteration scenarios. By stipulating the use of approved sealing materials for ductwork and setting forth clear guidelines for installations and replacements, including the precise forms needed for different alteration projects, the CF-1R-ALT-HVAC form plays a pivotal role in enhancing energy efficiency, system performance, and compliance with building codes, thus safeguarding both the environment and homeowner investments.

Preview - Cf 1R Alt Hvac Form

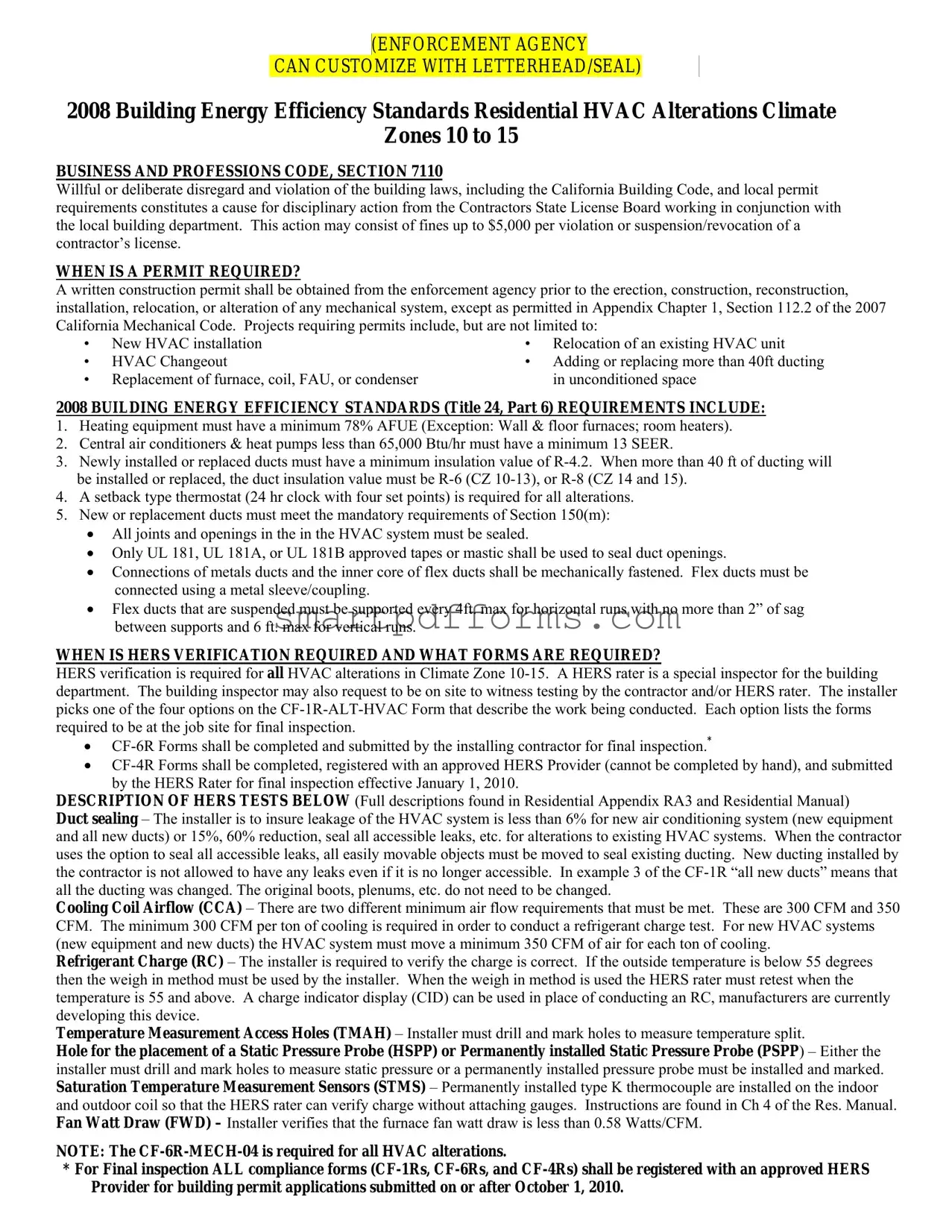

(ENFORCEMENT AGENCY CAN CUSTOMIZE WITH LETTERHEAD/SEAL)

2008 Building Energy Efficiency Standards Residential HVAC Alterations Climate

Zones 10 to 15

BUSINESS AND PROFESSIONS CODE, SECTION 7110

Willful or deliberate disregard and violation of the building laws, including the California Building Code, and local permit requirements constitutes a cause for disciplinary action from the Contractors State License Board working in conjunction with the local building department. This action may consist of fines up to $5,000 per violation or suspension/revocation of a contractor’s license.

WHEN IS A PERMIT REQUIRED?

A written construction permit shall be obtained from the enforcement agency prior to the erection, construction, reconstruction, installation, relocation, or alteration of any mechanical system, except as permitted in Appendix Chapter 1, Section 112.2 of the 2007 California Mechanical Code. Projects requiring permits include, but are not limited to:

• |

New HVAC installation |

• |

Relocation of an existing HVAC unit |

• |

HVAC Changeout |

• |

Adding or replacing more than 40ft ducting |

• Replacement of furnace, coil, FAU, or condenser |

|

in unconditioned space |

|

2008 BUILDING ENERGY EFFICIENCY STANDARDS (Title 24, Part 6) REQUIREMENTS INCLUDE:

1.Heating equipment must have a minimum 78% AFUE (Exception: Wall & floor furnaces; room heaters).

2.Central air conditioners & heat pumps less than 65,000 Btu/hr must have a minimum 13 SEER.

3.Newly installed or replaced ducts must have a minimum insulation value of

4.A setback type thermostat (24 hr clock with four set points) is required for all alterations.

5.New or replacement ducts must meet the mandatory requirements of Section 150(m):

•All joints and openings in the in the HVAC system must be sealed.

•Only UL 181, UL 181A, or UL 181B approved tapes or mastic shall be used to seal duct openings.

•Connections of metals ducts and the inner core of flex ducts shall be mechanically fastened. Flex ducts must be connected using a metal sleeve/coupling.

•Flex ducts that are suspended must be supported every 4ft. max for horizontal runs with no more than 2” of sag between supports and 6 ft. max for vertical runs.

WHEN IS HERS VERIFICATION REQUIRED AND WHAT FORMS ARE REQUIRED?

HERS verification is required for all HVAC alterations in Climate Zone

•

•

DESCRIPTION OF HERS TESTS BELOW (Full descriptions found in Residential Appendix RA3 and Residential Manual)

Duct sealing – The installer is to insure leakage of the HVAC system is less than 6% for new air conditioning system (new equipment and all new ducts) or 15%, 60% reduction, seal all accessible leaks, etc. for alterations to existing HVAC systems. When the contractor uses the option to seal all accessible leaks, all easily movable objects must be moved to seal existing ducting. New ducting installed by the contractor is not allowed to have any leaks even if it is no longer accessible. In example 3 of the

Cooling Coil Airflow (CCA) – There are two different minimum air flow requirements that must be met. These are 300 CFM and 350 CFM. The minimum 300 CFM per ton of cooling is required in order to conduct a refrigerant charge test. For new HVAC systems (new equipment and new ducts) the HVAC system must move a minimum 350 CFM of air for each ton of cooling.

Refrigerant Charge (RC) – The installer is required to verify the charge is correct. If the outside temperature is below 55 degrees then the weigh in method must be used by the installer. When the weigh in method is used the HERS rater must retest when the temperature is 55 and above. A charge indicator display (CID) can be used in place of conducting an RC, manufacturers are currently developing this device.

Temperature Measurement Access Holes (TMAH) – Installer must drill and mark holes to measure temperature split.

Hole for the placement of a Static Pressure Probe (HSPP) or Permanently installed Static Pressure Probe (PSPP) – Either the installer must drill and mark holes to measure static pressure or a permanently installed pressure probe must be installed and marked. Saturation Temperature Measurement Sensors (STMS) – Permanently installed type K thermocouple are installed on the indoor and outdoor coil so that the HERS rater can verify charge without attaching gauges. Instructions are found in Ch 4 of the Res. Manual. Fan Watt Draw (FWD) – Installer verifies that the furnace fan watt draw is less than 0.58 Watts/CFM.

NOTE: The

*For Final inspection ALL compliance forms

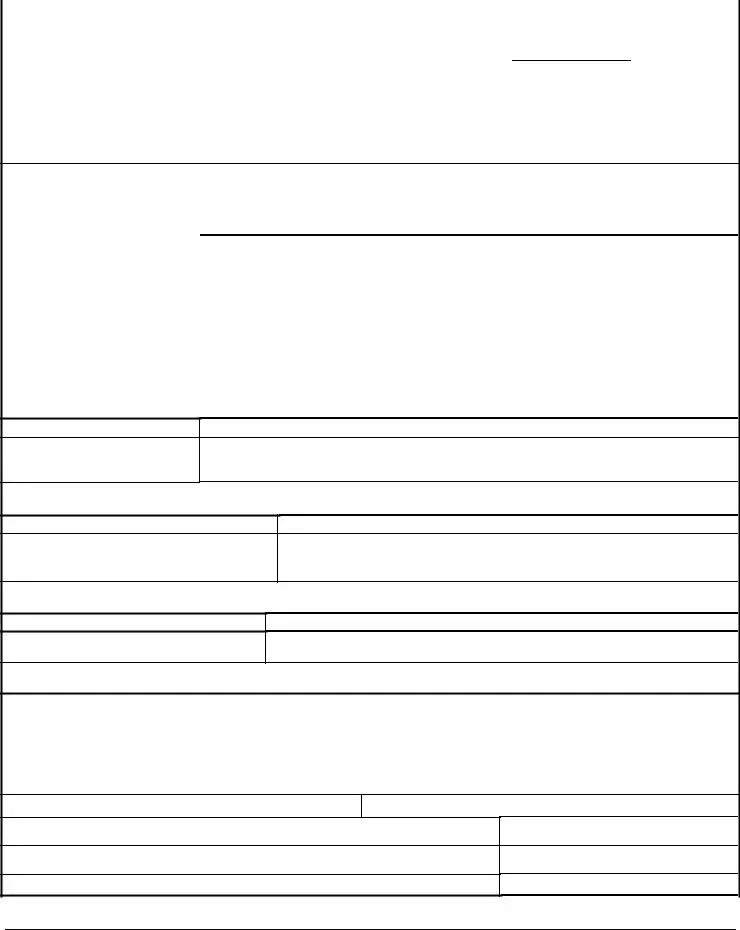

Simplified Prescriptive Certificate of Compliance: 2008 Residential HVAC Alterations |

||||||

Climate Zones 10 to 15 |

|

|

|

|

|

|

|

|

|

|

|

|

|

Site Address: |

|

|

Enforcement Agency: |

Date: |

|

Permit #: |

|

|

|

|

|

|

|

Equipment Type1 |

List Minimum Efficiency2 |

|

Conditioned Floor |

|

||

Duct insulation requirement |

Area |

|

Thermostat |

|||

Packaged Unit |

|

|

Over 40 ft of ducts added or |

|

|

Setback |

Furnace |

AFUE____ |

COP______ |

|

|

||

replaced in unconditioned space |

Served by system |

|

(If not already |

|||

Indoor Coil |

SEER_____ |

HSPF ____ |

|

|||

R 6 (CZ |

________ sf |

|

present, must be |

|||

Condensing Unit |

EER _____ |

Resistance |

|

|||

R 8 (CZ |

|

|

installed) |

|||

Other ________ |

|

|

|

|

||

|

|

|

|

|

|

|

1.Equipment Type: Choose the equipment being installed; if more than one system, use another

2.Minimum Equipment Efficiencies: 13 SEER, 78% AFUE, 7.7HSPF for typical residential systems.

HERS VERIFICATION SUMMARY Listed below are four HVAC alteration Options. The installer decides what work is being done and picks one of the appropriate Options. Each Option lists the HERS measures that must be conducted. A copy of the forms shall be left on site for final inspection and a copy given to the homeowner. At final, the inspector verifies that the work listed on this form was in fact the work completed by the installer. The inspector also verifies that each appropriate

1. HVAC Changeout |

Required Forms: |

|

• All HVAC Equipment replaced |

||

|

||

• Condenser Coil and /or |

||

• Indoor Coil and /or |

||

• Furnace |

||

|

For Split Systems: Duct leakage < 15 percent; RC, CCA ≥ 300 CFM/ton(Minimum Air Flow Requirement), TMAH

For Packaged Units: Duct leakage < 15 percent

Exempted from duct leakage testing if:

1. Duct system was documented to have been previously sealed and confirmed through HERS verification, or

2. Duct systems with less than 40 linear feet in unconditioned space, or

3. Existing duct systems are constructed, insulated or sealed with asbestos

2. New HVAC System

•Cut in or Changeout with new ducts: (all new ducting and all new equipment)

Required Forms:

For Split Systems: Duct leakage < 6 percent; RC, CCA ≥ 350 CFM/ton, FWD, TMAH, STMS, and either HSPP or PSPP.

For Packaged Units: Duct leakage < 6 percent

3. New Ducts with/or without Replacement

•Includes replacing or installing all new ducting and/or outdoor condensing unit and/or indoor coil and/or furnace. No or some equipment changed.

Required Forms:

For Split Systems: Duct leakage < 6 percent, RC, CCA ≥ 300 CFM/ton, TMAH

For Packaged Units: Duct leakage < 6 percent

4. New Ducting over 40 feet

• Includes adding or replacing more than 40

For split system or packaged units: Duct leakage < 15 percent

EXCEPTION: Existing duct systems constructed, insulated or sealed with asbestos.

Contractor (Documentation Author's /Responsible Designer's Declaration Statement)

•I certify that this Certificate of Compliance documentation is accurate and complete.

•I am eligible under Division 3 of the California Business and Professions Code to accept responsibility for the design identified on this Certificate of Compliance.

•I certify that the energy features and performance specifications for the design identified on this Certificate of Compliance conform to the requirements of Title 24, Parts 1 and 6 of the California Code of Regulations.

•The design features identified on this Certificate of Compliance are consistent with the information documented on other applicable compliance forms, worksheets, calculations, plans and specifications submitted to the enforcement agency for approval with the permit application.

Name:

Company:

Address:

City/State/Zip:

Signature:

Date:

License:

Phone:

2008 Residential Compliance Forms |

March 2010 |

Form Data

| Fact Name | Description |

|---|---|

| Purpose of the Form | This form is used for residential HVAC alterations in California's Climate Zones 10 to 15, under the 2008 Building Energy Efficiency Standards. |

| Governing Law | The form is guided by the Business and Professions Code, Section 7110, and adheres to the California Building Code and local permit requirements. |

| Permit Requirements | A construction permit must be obtained from the enforcement agency for any mechanical system work, except as allowed in the 2007 California Mechanical Code's Appendix Chapter 1, Section 112.2. |

| Energy Efficiency Requirements | Includes minimum AFUE for heating equipment, minimum SEER for air conditioners and heat pumps, duct insulation values, and a required setback type thermostat for alterations. |

| HERS Verification | HERS verification is mandatory for all HVAC alterations in the specified climate zones, with CF-6R and CF-4R forms required for final inspection. |

Instructions on Utilizing Cf 1R Alt Hvac

Filling out the CF-1R-ALT-HVAC form is a crucial step for contractors performing HVAC alterations in California's Climate Zones 10 to 15. This form ensures compliance with the 2008 Building Energy Efficiency Standards, underlining the importance of energy conservation and efficient system performance. Its completion is mandatory for the verification of proper installation and performance of HVAC systems, following specific energy-saving criteria. What follows is a streamlined process for filling out the form correctly to avoid legal repercussions and to ensure the HVAC system operates efficiently within the stipulated regulations.

- Start by identifying the enforcement agency: Customarily, the form allows for customization with the enforcement agency's letterhead or seal. Confirm the relevant details with the local building department.

- Understand the project requirements: Before proceeding, read the section regarding when a permit is required, ensuring your project meets the outlined criteria for permit necessity.

- Specify project details: In the section titled "2008 Building Energy Efficiency Standards (Title 24, Part 6) Requirements Include," provide specific details about the heating equipment, air conditioners, and duct insulation pertinent to your project.

- Fill in the site address and enforcement agency details: These are vital for record-keeping and verification purposes.

- Record the date and permit #: These ensure traceability and link the form to the specific permit issued for the HVAC alteration.

- List the types of equipment installed: Choose from the options provided (packaged unit, furnace, indoor coil, etc.) and specify the type used in your installation.

- Enter minimum efficiency ratings: This includes AFUE, COP, SEER, HSPF, EER, and resistance, ensuring they meet the stipulated minimums.

- Indicate the conditioned floor area served: This information helps in determining if the HVAC system sized is adequate for the area it serves.

- Specify duct insulation requirements: Based on the length of ductwork added or replaced, document the insulation value, i.e., R-6 (CZ 10-13) or R-8 (CZ 14 and 15).

- Choose the applicable HVAC alteration option: Select from one of the four options that best describes the work being conducted. Each option lists the required forms for compliance.

- Detail the Contractor (Documentation Author’s/Responsible Designer’s Declaration Statement): This section is a declaration of accuracy and compliance with applicable codes. Fill in the name, company, address, city/state/zip, signature, date, license, and phone.

Once the CF-1R-ALT-HVAC form is filled out, it's important to proceed with HERS verification and the submission of any additional required forms for final inspection. Keeping a copy of all documents at the job site is mandatory for review by the inspector at the final inspection stage. This ensures that all alterations are up to standard, promoting energy efficiency and system reliability.

Obtain Answers on Cf 1R Alt Hvac

When is a permit required for HVAC alterations?

A permit is needed for various HVAC-related activities including installing a new HVAC system, relocating an existing one, changing out HVAC equipment, adding or replacing more than 40 feet of ducting, or replacing certain components in unconditioned spaces. The California Building Code mandates obtaining this permit from the local enforcement agency before beginning any of the mentioned tasks. This ensures that all alterations comply with the established building laws and regulations, safeguarding the integrity and safety of the building's mechanical systems.

What are the 2008 Building Energy Efficiency Standards requirements for HVAC systems?

The 2008 Standards stipulate several requirements to enhance energy efficiency and performance of HVAC systems in residential settings, particularly for Climate Zones 10 to 15. Key standards include a minimum annual fuel utilization efficiency (AFUE) of 78% for heating equipment, a minimum seasonal energy efficiency ratio (SEER) of 13 for central air conditioners and heat pumps under 65,000 Btu/hr, and specific insulation values for ducts based on their location and length. Additionally, a setback type thermostat is required for all alterations, promoting better energy management and savings.

What is HERS verification and when is it required?

HERS verification is necessary for all HVAC alterations in Climate Zones 10 to 15. It involves a HERS (Home Energy Rating System) rater, who acts as a special inspector, ensuring that HVAC systems meet certain energy efficiency and performance criteria set forth by the California Energy Commission. Verification may include, but is not limited to, tests for duct sealing, cooling coil airflow, refrigerant charge, and others. The intent is to ensure that HVAC systems operate efficiently, which, in turn, reduces energy consumption and costs for homeowners.

What forms are required for final inspection of HVAC alterations?

For the final inspection process, several forms need to be completed and available on site. These include CF-6R Forms by the installing contractor and CF-4R Forms by the HERS rater. After January 1, 2010, CF-1R and CF-6R compliance forms must also be registered with an approved HERS Provider and present during final inspection. The specific forms required depend on the type of HVAC work being performed and the selected option on the CF-1R-ALT-HVAC Form that describes the work.

What penalties exist for non-compliance with building laws and permit requirements?

Failure to adhere to the building laws, including violations related to the California Building Code and local permit requirements, can lead to significant consequences. The Contractors State License Board, in coordination with the local building department, may impose fines up to $5,000 per violation or opt for suspension/revocation of a contractor's license. These measures underscore the importance of compliance and ensure that HVAC systems are installed or altered in accordance with the state's safety and efficiency standards.

Common mistakes

Filling out the CF-1R ALT-HVAC form for residential HVAC alterations in Climate Zones 10 to 15 under the 2008 Building Energy Efficiency Standards may seem straightforward. However, mistakes can easily occur if one is not cautious. The following outlines frequently encountered errors during this procedural necessity.

-

Permit Misunderstandings: Individuals often misconceive when a permit is required, neglecting to secure one for projects such as HVAC changeouts, installations, or duct replacements over 40ft, which are indeed mandate-driven necessities.

-

Inadequate Equipment Efficiency: Selection errors related to equipment efficiency often emerge, subverting minimum standards such as 78% AFUE for heating equipment and 13 SEER for central air conditioners and heat pumps, directly impacting system conformity and efficiency.

-

Duct Insulation Value: Overlooking the detailed insulation requirements based on duct length and specific Climate Zones (R-6 for Zones 10-13 when over 40ft of ducting is installed or replaced; R-8 for Zones 14 and 15) can result in non-compliance.

-

Setback Thermostat Requirements: The failure to install a setback type thermostat with all alterations, a device designed to enhance energy savings by adjusting the temperature based on a predefined schedule, is a frequently skipped mandate.

-

Incorrect Sealing Materials: Usage of non-approved sealing materials for ductwork compromises system integrity. Only UL 181, UL 181A, or UL 181B approved tapes or mastics are accepted for sealing duct openings, in alignment with strict guidelines.

-

HERS Verification Negligence: HERS (Home Energy Rating System) verification is a critical component of HVAC alterations that is often overlooked or misunderstood. Ignoring the necessity for HERS measures and the requirement for having corresponding forms on-site at the final inspection can invalidate the project.

-

Improper Form Completion: The meticulous completion of the CF-6R and CF-4R forms, essential for final inspection, is frequently marred by inaccuracies or the submission of unregistered forms, especially post October 1, 2010, when registration with an approved HERS provider became obligatory.

-

Eligibility and Compliance Documentation: The certification of compliance documentation suffers due to inadequate validation of the responsible designer’s eligibility under the California Business and Professions Code and failure to ensure that design features comply with the Title 24 regulations.

-

Missing Signatures and Details: A rather common but avoidable error, the absence of necessary signatures, licensing details, and accurate company information on the CF-1R ALT-HVAC form significantly delays processing and validation terms.

In sum, attentiveness to permits, equipment specifications, ductwork requirements, thermostats, appropriate materials use, HERS verification, form completion, eligibility, and compliance standards must be accorded in navigating the CF-1R ALT-HVAC form completion process to ensure adherence to the 2008 Building Energy Efficiency Standards.

Documents used along the form

When it comes to navigating the paperwork and compliance forms associated with residential HVAC alterations, especially in the context of California's 2008 Building Energy Efficiency Standards, understanding the breadth and depth of required documentation is crucial. The CF-1R-ALT-HVAC form serves as a cornerstone document for ensuring that HVAC installations or modifications in climate zones 10 to 15 meet or exceed state energy efficiency standards. However, this form doesn't stand alone. Several other forms and documents often accompany it, forming a comprehensive suite of paperwork that contractors and HVAC professionals must be familiar with. Here's a glimpse into some of these essential documents:

- Permit Application: Before the CF-1R-ALT-HVAC form comes into play, an initial step involves applying for a construction permit from the local enforcement agency. This document initiates the formal process for any mechanical system alteration requiring official approval.

- CF-6R Forms: These forms are submitted by the installing contractor for final inspection. They include detailed information about the mechanical alterations that have been carried out, ensuring that the work meets all relevant standards and requirements.

- CF-4R Forms: Completed and registered by a HERS rater, these forms are crucial for final inspection, especially for projects requiring Home Energy Rating System (HERS) verification. They provide evidence of compliance with specific energy efficiency and quality assurance measures.

- Duct Leakage Test Forms: Essential for both new installations and alterations involving ductwork, these forms record the results of duct leakage tests, demonstrating compliance with standards for air leakage.

- Manual J Load Calculation: Often required to ensure the HVAC system is properly sized according to the specific heating and cooling needs of the house. This calculation helps in selecting appropriately sized equipment.

- Equipment Efficiency Documentation: Manufacturers’ documentation verifying the efficiency ratings of the HVAC equipment being installed, such as SEER (Seasonal Energy Efficiency Ratio) for air conditioners or AFUE (Annual Fuel Utilization Efficiency) for furnaces.

- Installation Standards Compliance: This could include a variety of forms or documents that certify the installation was conducted in accordance with relevant standards and manufacturer instructions, ensuring optimal performance and safety of the HVAC system.

Together, these documents form a mosaic of mandatory and beneficial compliance and verification steps, facilitating a smooth path through inspection and approval processes. Ensuring that HVAC systems not only meet but exceed energy efficiency standards, contributes to a more sustainable and environmentally friendly future. For contractors, staying well-informed and prepared with the right forms at the right time is key to success in this regulated landscape.

Similar forms

The CF-6R-MECH-04 form is similar to the CF 1R Alt HVAC form as both are required for HVAC alterations to ensure compliance with the 2008 Building Energy Efficiency Standards for residential buildings. Both forms are integral for documenting and verifying the energy efficiency and proper installation of HVAC systems.

The CF-4R forms are similar because they, like the CF 1R Alt HVAC form, must be completed and submitted for final inspection to demonstrate compliance with HERS (Home Energy Rating System) measures. The CF-4R forms are specifically designed to be filled out by the HERS rater, whereas the CF 1R Alt HVAC form is filled out by the installing contractor.

The Simplified Prescriptive Certificate of Compliance shares a purpose with the CF 1R Alt HVAC form by detailing requirements for HVAC system alterations, such as equipment type and minimum efficiency standards. Both documents serve to verify that HVAC alterations meet the specific energy standards set forth in Title 24, Part 6 of the California Code of Regulations.

MECH-21-HERS and MECH-25-HERS forms are related to the CF 1R Alt HVAC form because they document specific HERS verification tasks related to duct sealing and system airflow, among others. These forms complement the CF 1R Alt HVAC form in ensuring that HVAC systems are installed and functioning according to the energy efficiency standards required.

The Building Permit Application correlates with the CF 1R Alt HVAC form as both must be submitted to the local enforcement agency. The CF 1R Alt HVAC form is a specialized document that supports the building permit application by providing technical details about the HVAC alteration project, ensuring it complies with building and energy codes.

Compliance Forms for Final Inspection, similar to the CF 1R Alt HVAC form, include several CF-6R and CF-4R forms that must be registered with an approved HERS provider and presented during the final inspection. This set of documents collectively ensures that the HVAC system alteration complies with California's energy efficiency and building standards.

The Residential Appendix RA3 and the Residential Manual, though not forms, provide comprehensive descriptions and procedures for HERS tests that the CF 1R Alt HVAC form references for compliance and verification. They serve as the technical backbone for the requirements listed in the CF 1R Alt HVAC form and its related documents.

The Documentation Author's/Responsible Designer's Declaration Statement on the CF 1R Alt HVAC form is akin to similar declarations or certifications required in other compliance documents. It serves to attest to the accuracy and completeness of the information provided, ensuring that the HVAC alterations abide by California's energy and building regulations.

Dos and Don'ts

Filling out the CF-1R-ALT-HVAC form accurately ensures compliance with 2008 Building Energy Efficiency Standards for residential HVAC alterations in Climate Zones 10 to 15. To help guide you through this process, here are key dos and don'ts:

- Do ensure that all information provided on the form is accurate and complete. Inaccuracies can lead to disciplinary actions, including fines and the suspension or revocation of a contractor's license.

- Do obtain a written construction permit from the enforcement agency prior to starting any HVAC alteration project as specified under the law.

- Do check the equipment type and minimum efficiency requirements are filled out correctly, adhering to the standards like 13 SEER for central air conditioners and a minimum 78% AFUE for heating equipment.

- Do complete HERS verification if required for your project and ensure the necessary HERS measures are conducted.

- Don't use hand-filled CF-4R forms for final inspection after January 1, 2010; these must be registered with an approved HERS Provider.

- Don't leave any section incomplete, especially the contractor’s declaration statement at the end of the form. This confirms your compliance and responsibility for the HVAC system's design and installation.

- Don't forget to leave a copy of all compliance forms (CF-1Rs, CF-6Rs, and CF-4Rs) at the job site for the final inspection, as required for building permit applications submitted on or after October 1, 2010.

- Don't overlook the importance of sealing all joints and openings in the HVAC system and using only approved materials for duct sealing, as mandated by the 2008 energy efficiency standards.

Adherence to these guidelines will help facilitate a smoother approval and inspection process, ensuring your HVAC alteration project complies with the state's energy efficiency requirements and building codes.

Misconceptions

Understanding the CF-1R-ALT-HVAC form, especially in the context of residential HVAC alterations in climate zones 10 to 15, is essential for adherence to the 2008 Building Energy Efficiency Standards. However, there are several misconceptions surrounding the form and its requirements. Here we aim to clarify these to ensure compliance and efficiency in HVAC alterations.

- Permit is optional: A common misconception is that permits are optional for HVAC alterations. However, as clearly stated in the form, a written construction permit is required from the enforcement agency prior to proceeding with any mechanical system alteration, except in specific exempted cases.

- HERS verification is always mandatory: While HERS verification is indeed required for all HVAC alterations in the specified climate zones, there are exceptions where certain conditions are met, reducing the perceived universality of this requirement.

- All HVAC system replacements require duct leakage tests: The requirement for duct leakage testing is conditional. For instance, systems with ducts previously confirmed sealed through HERS verification, or systems with less than 40 linear feet in unconditioned space, are exempt.

- Advanced sealing materials are unnecessary: Misinformation often downplays the need for specific sealing materials. The form mandates the use of only UL 181, UL 181A, or UL 181B approved tapes or mastic to seal duct openings, emphasizing the importance of quality and compliance in materials used.

- Manual registration of CF-4R forms is allowed: Contrary to this belief, CF-4R forms must be registered with an approved HERS provider and manually filled forms are not accepted. This enhances the regulatory oversight and standardization of the HVAC alteration process.

- Only new installations require efficiency standards compliance: Another misunderstanding is that only new HVAC installations must comply with the specified efficiency standards. Replacement units also need to meet minimum efficiency requirements, including AFUE, SEER, and insulation values, to ensure energy efficiency across all installations.

- Permits for minor duct work are unnecessary: The form clearly includes adding or replacing more than 40ft of ducting under activities requiring a permit. This corrects the assumption that permits are only for major HVAC system alterations and underlines the need for compliance in even relatively minor duct work.

Correcting these misconceptions is crucial for contractors, homeowners, and professionals involved in HVAC system alterations. It ensures that all work meets legal and efficiency standards, promoting energy conservation and compliance with the Building Energy Efficiency Standards.

Key takeaways

Filling out and using the CF-1R-ALT-HVAC form for residential HVAC alterations in Climate Zones 10 to 15 involves understanding a range of requirements and procedures crucial for compliance with 2008 Building Energy Efficiency Standards. Below are key takeaways for contractors and other stakeholders involved in HVAC installation, alteration, or replacement.

- Permit Requirements: Before beginning any HVAC project, including installation, relocation, or alteration, it is essential to obtain a written construction permit from the local enforcement agency, unless specific exceptions apply.

- Penalties for Non-Compliance: Deliberate violation of building laws or permit requirements may lead to disciplinary action including fines up to $5,000 per violation or suspension/revocation of a contractor’s license, emphasizing the importance of adherence to legal and regulatory standards.

- Equipment Efficiency Standards: Installed heating equipment must meet minimum efficiency standards such as 78% AFUE for heaters, 13 SEER for central air conditioners, and specific HSPF values for heat pumps, ensuring energy conservation and performance.

- Duct Insulation and Sealing: New or replaced ducts must have minimum insulation values (R-4.2, R-6, or R-8 depending on Climate Zones and extent of ductwork) and must be properly sealed using approved materials to reduce energy loss and improve system efficiency.

- Thermostat Requirements: All alterations require the installation of a setback type thermostat with a 24-hour clock and four set points, which contributes to energy savings by allowing automated temperature adjustments.

- HERS Verification: HVAC alterations in the specified climate zones require Home Energy Rating System (HERS) verification to ensure compliance with energy efficiency standards. This involves various tests including duct sealing, airflow, refrigerant charge, and others, depending on the nature of the work being done.

- Documentation and Final Inspection: Contractors are required to complete and submit CF-6R and CF-4R forms for final inspection. These forms document compliance with efficiency standards and HERS verification results, and must be registered with an approved HERS provider for projects submitted on or after October 1, 2010.

- Responsibility for Design: The CF-1R-ALT-HVAC form includes a declaration by the responsible designer or contractor attesting to the accuracy of the compliance documentation and conformity of the design to Title 24 requirements, highlighting the responsibility to ensure energy-efficient and compliant HVAC designs.

Understanding and correctly applying the instructions and requirements associated with the CF-1R-ALT-HVAC form is essential for legal compliance, energy efficiency, and the integrity of HVAC systems in residential buildings within the specified climate zones.

Popular PDF Forms

Wisconsin Instruction Permit - The form includes a certification process for applicants and sponsors, emphasizing the accountability in the driver licensing process.

Landlord Letter Statement From Non-relative Landlord - A formal and essential document for landlords to capture the rental specifics of their property, including comprehensive occupant information.