Blank Drop Ball Certificate PDF Template

In the realm of optical product safety, ensuring that lenses meet stringent impact resistance standards is crucial. The Drop Ball Test Certification serves as a pivotal document in this context, affirming that a specific set of articles adheres to the stringent criteria outlined in 21 CFR 801.410 regarding impact resistance. This certification is more than a mere formality; it is a manufacturer's guarantee that their lenses can withstand a certain degree of force without shattering, although it is explicitly stated that this does not render the lenses unbreakable or shatterproof. The requirement for manufacturers to maintain a record of testing for three years post-shipment and to provide this documentation to the FDA upon request underscores the importance of transparency and accountability in the industry. Additionally, the form necessitates detailed information, including the company’s name, address, the authorized individual’s name, and their signature, ensuring that the certification is both verified and traceable. The inclusion of a shipping detail, such as the Federal Express AWB#, further highlights the comprehensive nature of this certification, designed to track and maintain high safety standards across the optical industry.

Preview - Drop Ball Certificate Form

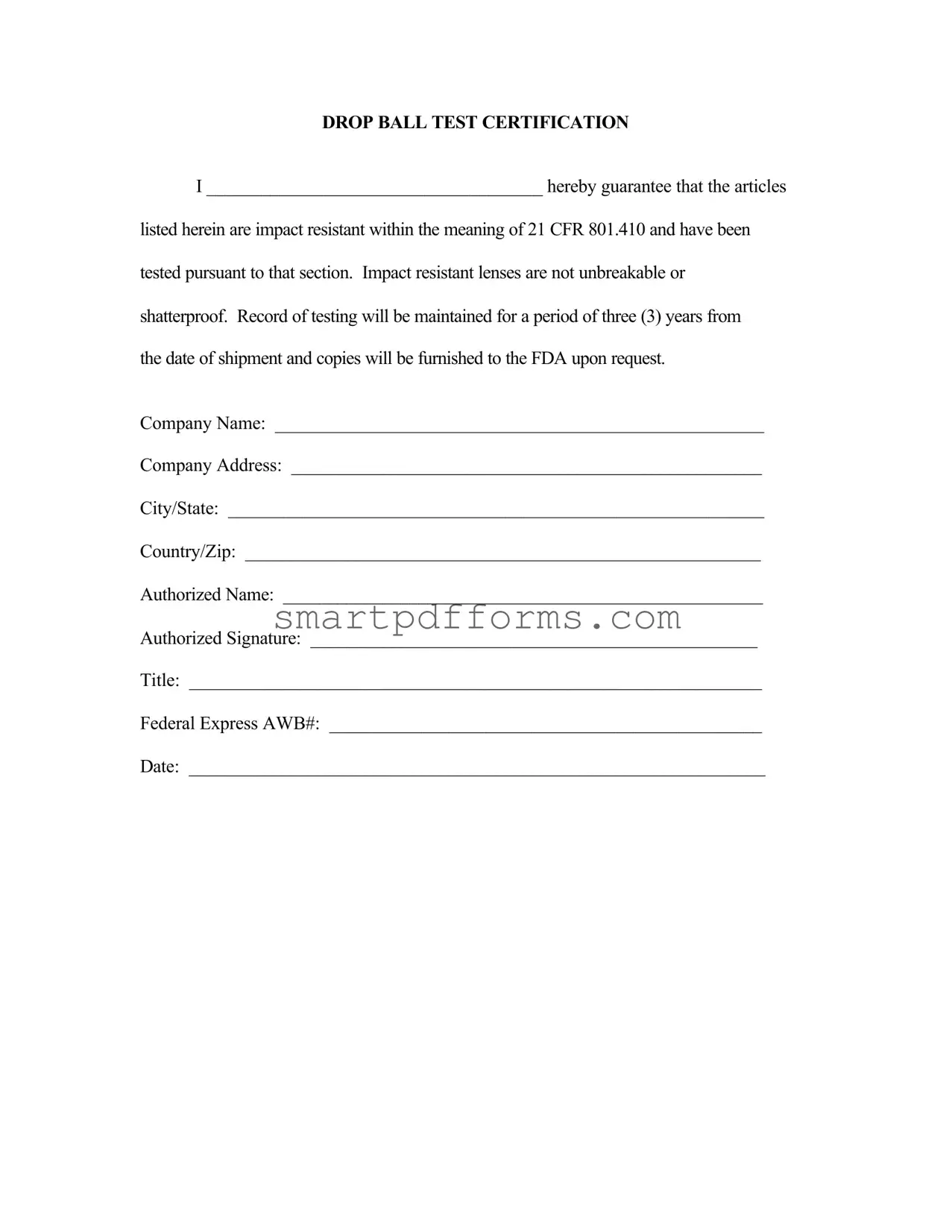

DROP BALL TEST CERTIFICATION

I _____________________________________ hereby guarantee that the articles

listed herein are impact resistant within the meaning of 21 CFR 801.410 and have been tested pursuant to that section. Impact resistant lenses are not unbreakable or shatterproof. Record of testing will be maintained for a period of three (3) years from the date of shipment and copies will be furnished to the FDA upon request.

Company Name: _____________________________________________________

Company Address: ___________________________________________________

City/State: __________________________________________________________

Country/Zip: ________________________________________________________

Authorized Name: ____________________________________________________

Authorized Signature: _________________________________________________

Title: ______________________________________________________________

Federal Express AWB#: _______________________________________________

Date: ______________________________________________________________

Form Data

| Fact | Detail |

|---|---|

| Purpose | The Drop Ball Test Certification confirms that articles (typically eyewear lenses) are impact resistant as defined under U.S. federal regulations. |

| Governing Law | 21 CFR 801.410, U.S. Food and Drug Administration (FDA) regulations. |

| Impact Resistant Clarification | While certified as impact resistant, the lenses are not guaranteed to be unbreakable or shatterproof. |

| Record Keeping Requirement | Manufacturers must maintain testing records for three years after the shipment date and must provide these records to the FDA upon request. |

| Required Information | The form requires detailed company information, the name and signature of an authorized representative, Federal Express AWB#, and the date. |

Instructions on Utilizing Drop Ball Certificate

Filling out the Drop Ball Certificate form is a straightforward process, designed to ensure that the eyewear products being sold meet safety standards for impact resistance. This certification is crucial for companies in the eyewear industry, as it provides a guarantee that their products have been tested and comply with specific regulatory requirements. The form serves as a formal declaration and must be accurately completed to avoid any compliance issues. Follow the steps below to fill out the Drop Ball Certificate form correctly.

- Begin by typing your full name in the blank space provided after "I," to indicate that you are the person making the guarantee.

- In the "Company Name" field, enter the official registered name of your company.

- Fill in the "Company Address" section with your company's full physical address, including street name and number.

- Type the city and state where your company is located in the "City/State" field.

- Enter your company's country and zip code in the "Country/Zip" field.

- In the "Authorized Name" section, write the name of the individual who is authorized to sign this certificate on behalf of the company.

- The "Authorized Signature" space is where the authorized individual must sign to validate the certificate. Make sure this signature matches with the authorized name provided.

- Specify the title of the authorized signer in the "Title" field (e.g., CEO, Manager, Compliance Officer).

- For shipments that are sent via Federal Express, include the Air Waybill number (AWB#) in the designated field. This helps in tracking the shipment of the tested products.

- Finally, enter the date the form is being filled out and signed in the "Date" field. Make sure this date is accurate, as it determines the start of the three-year record-keeping period.

After completing the form, it's important to keep a copy for your records. This document may be required by the Food and Drug Administration (FDA) at any time within the three-year record-keeping period. Ensuring that this form is filled out accurately and retained properly is key to demonstrating compliance with the impact resistance requirements.

Obtain Answers on Drop Ball Certificate

What is a Drop Ball Certificate form?

A Drop Ball Certificate form verifies that a particular set of eyewear products has undergone and passed an impact resistance test. This test is crucial to ensure that the eyewear meets the safety standards outlined in 21 CFR 801.410. By signing this certificate, the individual confirms the eyewear's compliance and its ability to withstand a certain level of impact without breaking. However, it's important to note that while the lenses are impact resistant, they are not unbreakable or shatterproof. This distinction underscores the importance of careful handling and usage of the eyewear to prevent damage or injury.

Who needs to complete the Drop Ball Certificate form?

Manufacturers or distributers of eyewear products are required to complete the Drop Ball Certificate form. This is a mandatory step for those intending to market their eyewear products in areas where compliance with the 21 CFR 801.410 standard is regulated. It is the responsibility of the company's authorized representative to fill out and sign the form, thereby guaranteeing the impact resistance of their eyewear products. By doing so, the authorized individual attests to the quality and safety of the products prior to their distribution or sale.

How long must records of the Drop Ball Test be maintained?

Records of the Drop Ball Test must be kept for a minimum of three (3) years following the date of shipment. This period allows for proper documentation and enables companies to furnish copies of the test results to the Food and Drug Administration (FDA) upon request. Maintaining these records is not only a regulatory requirement but also serves as an important internal document that can be referenced in the future to verify compliance or in the event of a safety audit. Keeping thorough and accurate records ensures transparency and accountability in the manufacturing and distribution process.

What does it mean if the eyewear is "impact resistant" according to 21 CFR 801.410?

When eyewear is labeled as "impact resistant" under the regulation 21 CFR 801.410, it means the eyewear has been tested and proven to withstand a specified level of impact without breaking. This standard is essential for protecting consumers, ensuring that the eyewear offers a basic level of protection against injuries that could occur from everyday accidents. However, "impact resistant" does not imply that the eyewear is unbreakable or shatterproof. Consumers should be aware that while these products are designed to offer more durability than non-compliant eyewear, they still require careful handling and are not indestructible.

Common mistakes

Completing the Drop Ball Certificate form accurately is crucial for compliance with the 21 CFR 801.410 regulation. Nonetheless, individuals frequently make errors during the filling process. Noting these common mistakes can help ensure the form is completed correctly, thus maintaining compliance and avoiding potential legal issues.

Not providing full and accurate company information. It is essential to include the complete name and address of the company. This includes the city, state, country, and zip code without abbreviations or errors to ensure the information is traceable and verifiable.

Omitting the authorized name and signature. The form requires the name and signature of an individual authorized by the company. This attests to the accuracy of the information provided and the compliance of the tested articles with the specified impact resistance standards. Failure to include a clear authorized name and signature could invalidate the certificate.

Incorrectly identifying the articles tested. Specific details about the articles that were subjected to the drop ball test must be unmistakably listed. Vague descriptions or omitting the particulars can lead to misunderstandings about what has been certified as impact resistant, thus calling the certification's validity into question.

Forgetting to maintain and offer test records. The certification states that records of testing will be kept for three years and furnished to the FDA upon request. Not adhering to this record-keeping requirement can lead to compliance issues if the FDA seeks to verify the certification's authenticity.

Leaving the date and Federal Express AWB# blank. The date of issuance and the Federal Express Air Waybill number (Federal Express AWB#) are critical for tracking the shipment of the tested articles and validating the certificate's timing. Neglecting to fill these fields can compromise the document's traceability and regulatory compliance.

By closely adhering to the form's requirements and avoiding these common mistakes, companies can help ensure their Drop Ball Test Certification is beyond reproach, thus safeguarding their products' marketability and compliance with regulatory standards.

Documents used along the form

When dealing with the Drop Ball Certificate form, which certifies that specific articles meet the impact resistance requirements outlined by federal regulations, several other documents are commonly required to ensure full compliance and traceability. These documents play a crucial role in the product testing and certification process, providing essential details and evidence that complement the certification provided by the Drop Ball Certificate.

- Quality Control Logs: These records detail the internal quality checks conducted during the manufacturing process. They demonstrate ongoing compliance with established standards and are critical in case of an audit by regulatory agencies.

- Product Specifications Sheet: This document outlines the product’s design, materials, and intended use. It provides the technical details necessary to assess the product's compliance with specific safety standards, including impact resistance.

- Testing Procedure Documentation: Written protocols for how the drop ball test and other required product safety tests are performed are crucial. This documentation ensures repeatability and validity of the testing process, providing a step-by-step guide that must be followed to meet regulatory requirements.

- Compliance Statement: A formal declaration by the manufacturer or distributor, stating that the product meets all relevant standards and regulations. This statement often references the specific standards and testing methods used, including the Drop Ball Test, to assert compliance.

Together, these documents form a comprehensive portfolio demonstrating a product's compliance with impact resistance and other safety standards. Ensuring that these documents are accurately maintained and readily available is essential for meeting regulatory requirements and supporting the certification provided by the Drop Ball Certificate.

Similar forms

Documents similar to the Drop Ball Test Certification form extend across various industries, involving certifications, guarantees, and compliance attestations. Each reflects commitments to certain standards, embodying proof of conformance with regulatory, safety, or quality criteria. Here are seven documents bearing resemblance to the Drop Ball Test Certification form, primarily through their mutual role in assuring and documenting compliance or standards adherence:

Certificate of Compliance (CoC): Just like the Drop Ball Certificate, a Certificate of Compliance is a declaration by manufacturers that their product meets the required standards set by regulatory bodies. It often pertains to safety, health, and environmental specifications, similar to how the Drop Ball Certificate verifies impact resistance as per specific federal regulations.

Material Safety Data Sheet (MSDS): Although focusing on chemical properties and handling precautions, the MSDS parallels the Drop Ball Certificate in its role of ensuring safety standards are met. It provides information on the safe use and potential hazards of a chemical product, fulfilling regulatory requirements much like the impact resistance certification does for eyewear.

Quality Assurance Certificates: These certificates, akin to the Drop Ball Certification, affirm that a product or service has undergone rigorous testing and meets the predefined quality standards. They demonstrate a commitment to maintaining a certain level of quality, reassuring clients and regulators of the product's reliability.

CE Marking: Required for many products sold within the European Economic Area, the CE Marking signifies that a product meets EU safety, health, and environmental protection requirements. This is similar to the Drop Ball Certificate's role in ensuring eyewear complies with specific safety standards in the United States.

FCC Declaration of Conformity: This declaration indicates that an electronic device complies with Federal Communications Commission (FCC) standards for electromagnetic interference. Like the Drop Ball Certificate, it serves as a form of assurance to both consumers and regulatory bodies that the products adhere to important safety and performance standards.

ISO Certification: International Standards Organization (ISO) certificates validate that a manufacturing process, service, or documentation procedure has all the requirements for standardization and quality assurance. Though broader in scope, these certificates share the commitment to standards verification evident in the Drop Ball Test Certification.

UL Listing: Similar to the Drop Ball Certificate, a UL Listing from Underwriters Laboratories signifies that a product has been tested and meets specific, defined requirements for safety. This mark is essential for products seeking access to particular markets, ensuring they adhere to safety standards.

Each of these documents, while distinct in its specific application or industry focus, carries the underlying principle of certifying adherence to established standards—whether those be for safety, quality, or environmental stewardship. The Drop Ball Certificate form, pivotal in confirming eyewear impact resistance, embodies this commitment to regulatory compliance and consumer safety, mirroring the core function present in the enumerated certifications and declarations.

Dos and Don'ts

Filling out the Drop Ball Certificate form accurately is essential for compliance with regulatory standards. This document is critical in certifying that eyewear products meet the impact resistance requirements as stated in 21 CFR 801.410. To ensure that the process is completed correctly, here are a few guidelines on what you should and shouldn't do.

Things you should do:- Ensure accuracy of information: Double-check all entered information to ensure it is correct and matches the company and product records.

- Print clearly: Use legible handwriting or type the information to prevent any misunderstandings or misinterpretations of the data provided.

- Maintain records diligently: Keep a thorough record of the testing for three years, as these may need to be presented to the FDA upon request.

- Include all required details: Make sure to fill out every field, including company name, address, authorized name, and other pertinent information.

- Verify impact resistance claim: Before signing the certificate, ensure that the articles listed have been properly tested for impact resistance as per the described standards.

- Use an authorized signatory: The certificate must be signed by an individual who has the authority to guarantee compliance on behalf of the company.

- Overlook any sections: Skipping any parts of the form can lead to non-compliance issues.

- Assume durability guarantees: Remember to clarify that while lenses are impact resistant, they are not unbreakable or shatterproof.

- Use unofficial titles: The title used should accurately reflect the signatory’s position within the company.

- Postpone record maintenance: Failure to maintain proper records from the date of shipment could result in regulatory penalties.

- Sign without authorization: Unauthorized signatures could invalidate the certification.

- Ignore the specifics of CFR 801.410: It’s crucial to understand and follow the specific requirements outlined in 21 CFR 801.410 when performing impact resistance tests.

Misconceptions

When it comes to the Drop Ball Certificate form, there are several misconceptions that can lead to confusion for manufacturers, distributors, and even the regulatory bodies involved. Understanding these misconceptions is crucial for ensuring compliance and the safety of eyewear products. Here are four common misunderstandings about the Drop Ball Certificate form:

- Misconception 1: The test guarantees unbreakable lenses. While the Drop Ball Test is designed to ensure that lenses are impact resistant, it does not mean the lenses are unbreakable or shatterproof. The certification confirms that the articles have met the minimum requirements for impact resistance as outlined, but it does not imply that the lenses are indestructible.

- Misconception 2: Once tested, no further action is required. It's important to note that maintaining a record of testing is necessary for a period of three years from the date of shipment. These records must be readily available and copies should be furnished to the FDA upon request, indicating that ongoing compliance and record-keeping are essential parts of the certification process.

- Misconception 3: Any company can issue the Drop Ball Certificate. Only authorized personnel within the company can issue the Drop Ball Certificate. The form requires the authorized name and signature, along with the date and other company details, to ensure that the certification is valid and reliable. This ensures that the testing and certification process is handled by individuals with the proper authority and understanding of the regulatory requirements.

- Misconception 4: The certificate is only relevant in the United States. While the test criteria are based on regulations set forth by the U.S. Food and Drug Administration (FDA), the implications of the certification have a broader reach. Many countries look to FDA standards when considering their own regulations, and compliance with these standards can be a prerequisite for entering various markets. Therefore, understanding and adhering to the criteria set by the Drop Ball Test can have international implications for businesses.

Understanding these misconceptions and the realities behind the Drop Ball Certificate form can help manufacturers and distributors ensure that they are meeting all necessary regulatory requirements. This not only aids in compliance but also contributes to the safety and effectiveness of the eyewear products available to consumers.

Key takeaways

The Drop Ball Certificate form is a vital document for manufacturers and suppliers in the eyewear industry. Below are key takeaways to consider when filling out and using this form:

- Guarantee of Impact Resistance: The form serves as a guarantee that the listed articles (eyewear lenses) are impact resistant, which is essential for consumer safety.

- Compliance with 21 CFR 801.410: By filling out the form, you affirm that the lenses have been tested in accordance with the regulations stipulated in 21 CFR 801.410.

- Clarification on Lens Durability: It is important to note that while the lenses are impact-resistant, they are not guaranteed to be unbreakable or shatterproof. This distinction must be understood to set proper expectations.

- Record-Keeping Requirements: The form mentions that a record of testing will be maintained for three years from the date of shipment, highlighting the importance of good record-keeping practices.

- Availability to the FDA: Upon request, copies of the testing records must be furnished to the FDA, emphasizing the need for accessibility and transparency of documentation.

- Detailed Company Information: The form requires comprehensive details about the company, including name, address, authorized name, and signature. This ensures accountability and traceability.

- Shipping Information: The inclusion of Federal Express AWB# indicates the need for tracking shipment details, which could be critical for logistics and verification purposes.

- Date of Certification: The form must be dated, providing a specific timeframe regarding the guarantee of impact resistance and the period of record maintenance.

- Legal and Regulatory Implications: Filling out and submitting the Drop Ball Certificate form correctly is crucial for legal and regulatory compliance. It serves as a protective measure for both consumers and businesses.

Popular PDF Forms

Ks Dept of Corrections - Explains the allocation and assignment of visiting space within facilities, addressing logistical aspects of managing visitor flow.

Mobile Home Listing Agreement - A precise agreement that delineates the duties of a listing agent in selling a mobile home, along with the financial aspects involved.

Nbi Registration Form - Occupation and highest educational attainment provide a brief overview of the applicant’s background.