Blank Haccp PDF Template

In the realm of food safety management, the HACCP (Hazard Analysis and Critical Control Points) form plays a pivotal role in ensuring that food establishments maintain high standards of food safety and hygiene. This comprehensive document comprises several sections, each designed to guide food establishments through the process of analyzing and monitoring critical points in their operation that may pose a risk to food safety. At the heart of the HACCP form is the Hazard Analysis Table, which helps in identifying potential chemical, physical, and biological hazards at various processing steps and determining their significance. It further provides a structured approach to documenting justifications for decisions made, preventive measures, and whether a step is considered a Critical Control Point (CCP). Alongside, the form includes a ROP (Reduced Oxygen Packaging) HACCP Plan Summary, which outlines critical limits for each control measure, monitoring procedures, and corrective actions. To ensure the accuracy of temperature controls, the Refrigeration/Freezer Log, and Thermometer Calibration Log are integral components, capturing critical temperature readings, calibration details, and corrective measures taken to address deviations. Additionally, the Corrective Action Log allows for detailed recording of any deviations from set standards, the causes behind these deviations, and the measures taken to prevent their recurrence. Together, these elements underscore the importance of vigilance and consistent record-keeping in maintaining food safety, making the HACCP form a vital tool for all food establishments committed to upholding the highest standards of food safety.

Preview - Haccp Form

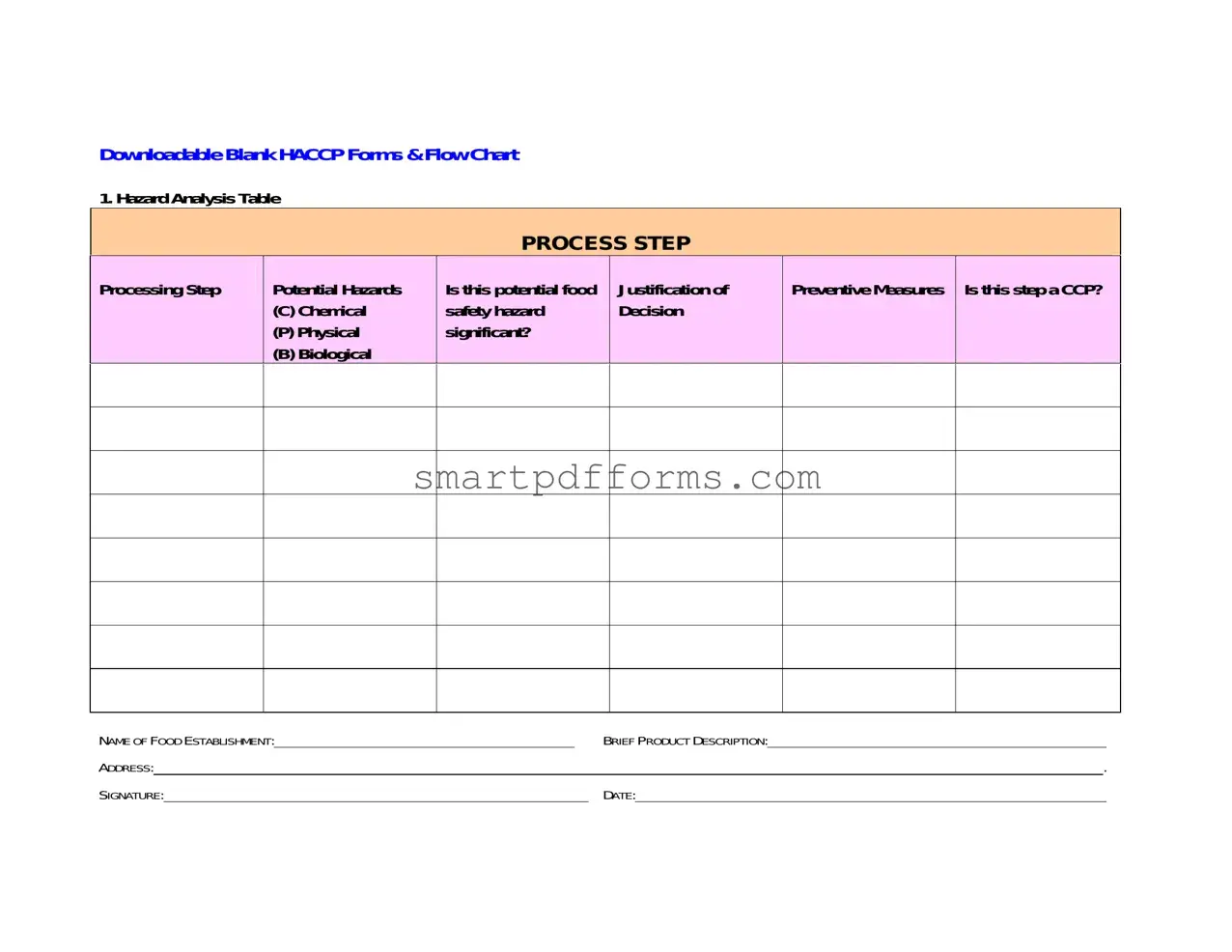

Downloadable Blank HACCP Forms & Flow Chart

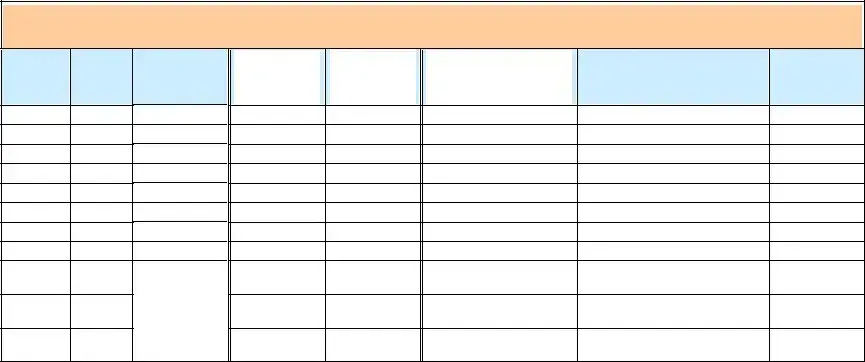

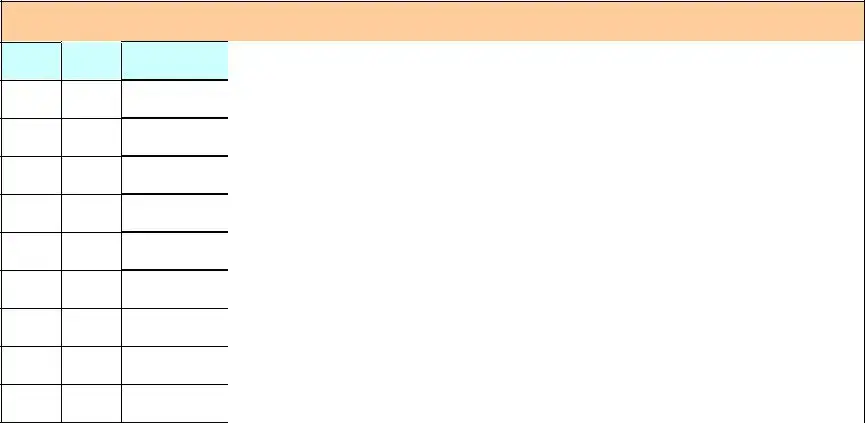

1. Hazard Analysis Table

PROCESS STEP

Processing Step

Potential Hazards

(C)Chemical

(P)Physical

(B)Biological

Is this potential food safety hazard significant?

Justification of Decision

Preventive Measures Is this step a CCP?

NAME OF FOOD ESTABLISHMENT: |

|

BRIEF PRODUCT DESCRIPTION: |

||||||

ADDRESS: |

|

|

|

|

. |

|||

SIGNATURE: |

|

|

DATE: |

|||||

|

|

|

|

|

|

|

|

|

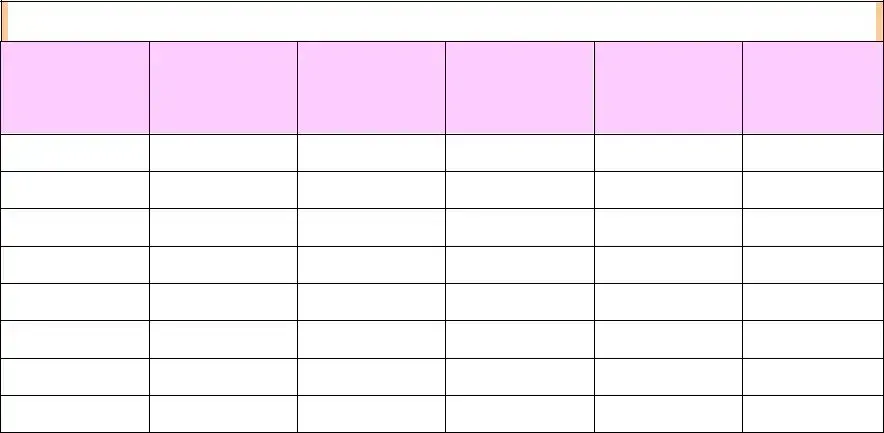

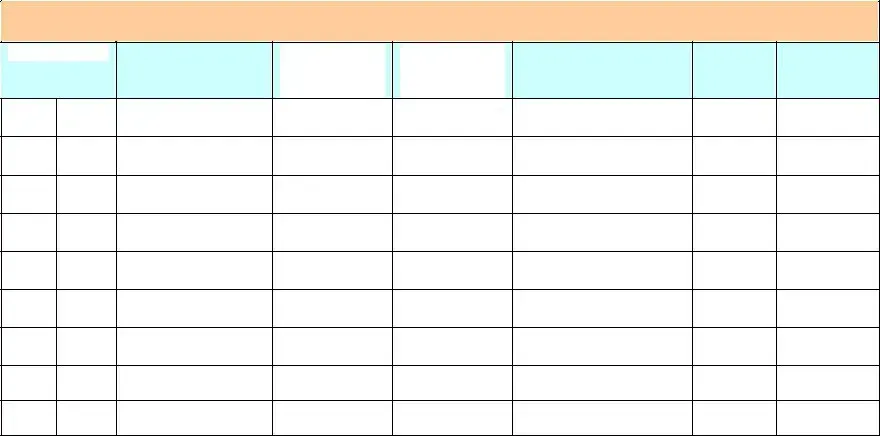

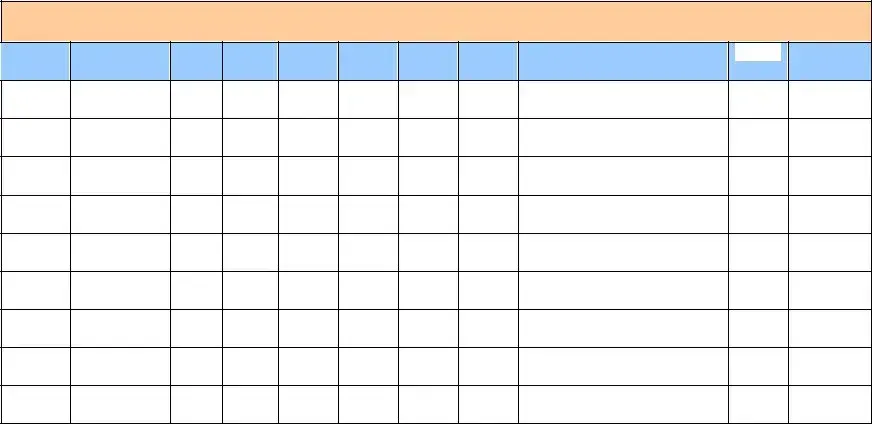

2.ROP HACCP Plan Summary

CCP

Critical Control Point (CCP)

Hazard

Description

Critical Limits

for each Control

Measure

Monitoring

What |

How |

Frequency |

Who |

|

|

|

|

|

|

|

|

Corrective Verification

Action Activities

Record- keeping Procedures

NAME OF FOOD ESTABLISHMENT: |

|

BRIEF PRODUCT DESCRIPTION: |

||||||

ADDRESS: |

|

|

|

|

. |

|||

SIGNATURE: |

|

|

DATE: |

|||||

|

|

|

|

|

|

|

|

|

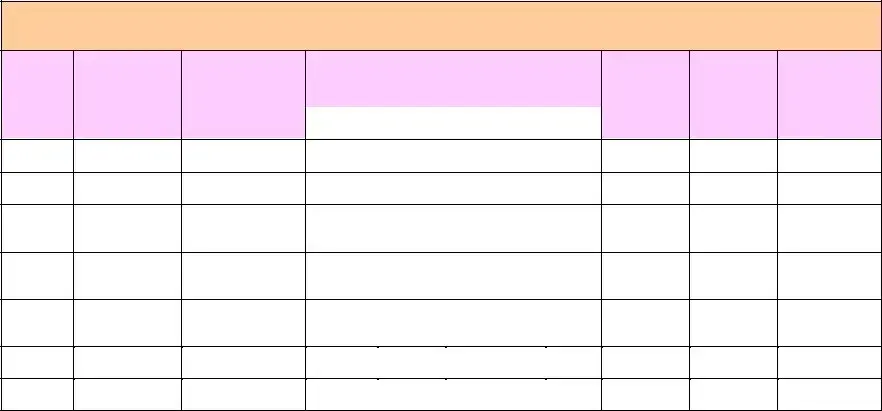

3. Refrigeration / Freezer Log

Refrigeration / Freezer Log

Location/

Unit Description

Date

Time

Temperature

Corrective Action

Food Worker

Initials

Manager

Initials / Date

Instructions: A designated foodservice employee will record the location or description of holding unit, date, time, air temperature, corrective action, and initials on this Log. The supervisor of the food operation will verify that foodservice workers have taken the required temperatures by visually monitoring food workers during the shift and reviewing, initialing, and dating this log daily. This log should be maintained for a minimum of 90 days after the food has been consumed.

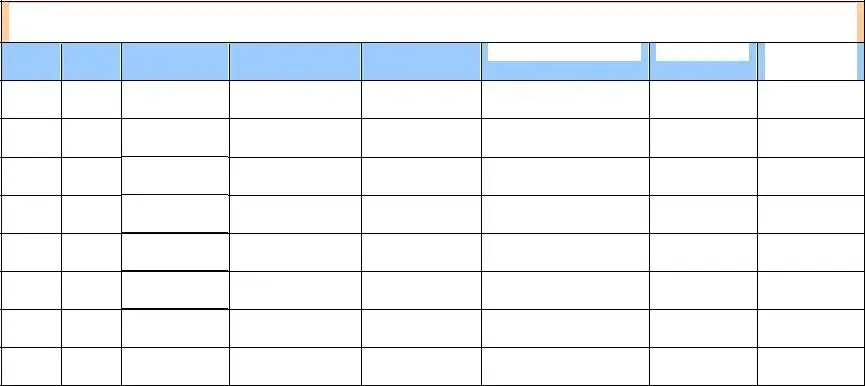

4. Thermometer Calibration Log

Thermometer Calibration Log

Date Time

Test Reference

Thermometer Thermometer

ID# Reading

Test

Thermometer

Reading

Adjustments Required

(Yes / No)

Corrective Action

Initials

Verification (Records Review) by and Date: ________________________________

Instructions: Foodservice workers will record the calibration temperature and corrective action taken each time thermometer is calibrated. The supervisor of the food operation will verify that foodservice employees are using and calibrating thermometers properly by making visual observations of employee activities during all hours of operation. The supervisor of the operation will review and initial the log daily. This log should be maintained for a minimum of 90 days after the food has been consumed.

Thermometers intended for measuring hot temperature items, such as cooked product, will be calibrated in hot water, while those used for taking lower temperatures will be calibrated in ice water. All thermometers will be calibrated within + or – 2 degrees F.

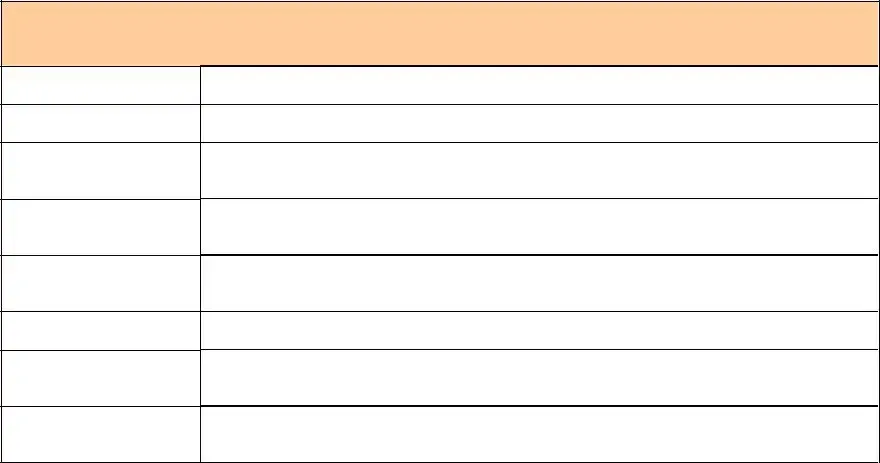

5. Corrective Action Log

Product:

Date / Time:

Deviation:

Cause of Deviation:

Cause of Deviation Eliminated By:

CCP Under Control After Corrective Actions Taken:

Preventative Measures:

Corrective Action Log

Lot ID:

Designated Food Worker:

Product Disposition:

Verification (Records Review) by and Date: |

________________________________ |

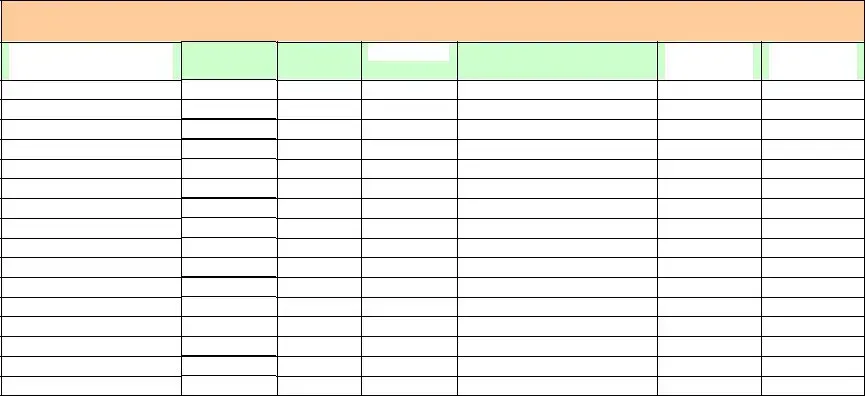

6. Cooking & Reheating Temperature Log

Cooking and Reheating Temperature Log

Date and Time

Food Item

Internal

Temperature /

Time

Internal

Temperature /

Time

Corrective Action Taken

Initials |

Verified By / Date

Instructions: Record product name, time, the two temperatures/times, and any corrective action taken on this form. The supervisor of the food operation will verify that food workers have taken the required cooking temperatures by visually monitoring food workers and preparation procedures during the shift and reviewing, initialing, and dating this log daily. This log should be maintained for a minimum of 90 days after the food has been consumed.

7. Holding Times & Temperatures

Holding Times and Temperatures

Date |

Food Item |

1st Measurement |

2nd Measurement |

Corrective Action |

||||

(e.g. enter holding) |

(e.g. exit holding) |

|||||||

|

|

Time |

Temp |

Initials |

Time |

Temp |

Initials |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Supervisory Employee’s Initials and Date: ______________________

Instructions: Take and record the temperature of the food when placed in holding units and when removed from holding units. If pans are moved directly from ovens to holding units, simply record the end cooking temperature on this form.

8. Receiving Log

Date |

Time |

Vendor |

|

|

or Supplier |

Receiving Log (Transporting)

Product Name |

Temperature (oF) |

Corrective Action Taken |

Initials/Date |

Manager |

|

|

|

|

Initials/Date |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Instructions: Use this Log for deliveries or receiving foods from suppliers. Record any temperatures and corrective action taken on the Receiving Log. The supervisor of the food operation will verify that foodservice workers are receiving products using the proper procedure by visually monitoring foodservice workers during the shift and reviewing the log daily. The Receiving log should be maintained for a minimum of 90 days after the food has been consumed.

9. Cooling Temperature Log

Cooling Temperature Log

Date

Food Item

Time / Temp

Time / |

Temp |

Time / Temp

Time / Temp

Time / Temp

Time / Temp

Corrective Actions Taken

Initials

Verified

By / Date

Instructions: Record temperatures every hour during the cooling cycle. Record corrective actions, if applicable. If no foods are cooled on any working day, indicate “No Foods Cooled” in the Food Item column. The supervisor of the food operation will verify that the designated food worker is cooling food properly by visually monitoring the food worker during the shift and reviewing, initialing, and dating the log daily. The Cooling Log should be kept for a minimum of 1 year.

10. Damaged or Discarded Product Log

Damaged or Discarded Product Log

Date |

Time |

Vendor |

|

|

or Supplier |

Product Name

Temperature

Corrective Action Taken

Initials/Date

Manager

Initials/Date

Instructions: Designated food worker will record product name, quantity, action taken, reason, initials, and date each time a food or food product is damaged and/or will be discarded. The supervisor the food operation will verify that food workers are discarding damaged food properly by visually monitoring foodservice workers during the shift and reviewing, initialing, and dating this log daily. The Damaged or Discarded Product Log should be. maintained for a minimum of 90 days after the food has been consumed.

Form Data

| Fact Name | Description |

|---|---|

| Function of the HACCP Form | Designed to ensure food safety through identifying and controlling hazards, from biological to chemical and physical. |

| Hazard Analysis Table | Part of the form where food establishments detail steps in processing, potential hazards, and measures for prevention, including identification of Critical Control Points (CCP). |

| Monitoring and Verification | These sections are crucial for verifying that the hazard control measures are effective, detailing monitoring actions, frequencies, and the individuals responsible. |

| Temperature Control Logs | Includes Refrigeration/Freezer Logs and Thermometer Calibration Logs to ensure temperatures are appropriately maintained and devices are accurate, crucial for food safety. |

| Corrective Action Logs | Documents any deviations from critical limits, the causes, and corrective actions taken to maintain food safety, including verification of these actions. |

Instructions on Utilizing Haccp

Successfully filling out the HACCP form is crucial for maintaining the safety and quality of food within your establishment. The process may seem daunting at first, but by following these step-by-step instructions, you can ensure that every section of the form is completed accurately. After you’ve filled out the form, it will be your blueprint for identifying potential food safety hazards, outlining critical control points, and establishing monitoring procedures. This document will guide your team in maintaining the highest standards of food safety, helping to protect both your customers and your business.

Steps for Completing the HACCP Form

- Hazard Analysis Table:

- Enter the name of the food establishment and provide a brief product description.

- List every processing step under "PROCESS STEP".

- Identify potential hazards (chemical, physical, biological) associated with each step.

- Determine if the identified hazard is significant and provide justification for your decision.

- Describe preventative measures for each hazard.

- Identify if the step is a CCP (Critical Control Point).

- Include the address of the food establishment, your signature, and the date.

- ROP HACCP Plan Summary:

- Fill in the name and address of the food establishment and give a brief product description.

- Identify each CCP and describe the associated hazard.

- Detail critical limits for each control measure.

- Outline monitoring procedures including what will be monitored, how, how often, and by whom.

- Describe corrective actions to be taken when monitoring indicates a critical limit deviation.

- Explain verification activities and record-keeping procedures.

- Sign and date the form.

- Refrigeration / Freezer Log:

- Record the location/description of the unit, date, time, and air temperature.

- Note any corrective action taken.

- Food worker and manager should initial and date the log.

- Maintain the log for a minimum of 90 days after the food has been consumed.

- Thermometer Calibration Log:

- Log the date, time, and thermometer ID# for each calibration.

- Record test and reference thermometer readings, and note if adjustments are required.

- Document any corrective action taken.

- The supervisor should verify, initial, and date the log daily.

- Maintain the log for a minimum of 90 days after food consumption.

- Corrective Action Log:

- Record the product name, date/time, and the nature of the deviation.

- Document the cause of the deviation and how it was eliminated.

- Confirm the CCP is under control after corrective actions are taken.

- List preventative measures to avoid future deviations.

- Log the lot ID, designated food worker, and product disposition.

- A designated authority should review the records, sign, and date the form.

Successfully completing the HACCP form is an ongoing process that requires diligence and attention to detail. Regularly reviewing and updating your HACCP plan in response to changes in product, process, or regulatory requirements is essential for continued compliance and safety. Should questions or concerns about filling out the form arise, consider consulting with a food safety expert or your local health department for guidance.

Obtain Answers on Haccp

-

What is a HACCP Form, and why is it important?

HACCP, standing for Hazard Analysis and Critical Control Points, is a systematic preventive approach to food safety. It identifies physical, chemical, and biological hazards in production processes that can cause the finished product to be unsafe and designs measurements to reduce these risks to a safe level. This form is crucial as it helps food establishments to document and establish a plan to ensure the safety of the food they produce, handling everything from receiving raw materials to serving the product to the consumer. By using HACCP forms, businesses demonstrate their commitment to food safety and compliance with local and international regulations.

-

How does the Hazard Analysis Table work?

The Hazard Analysis Table is a tool used within the HACCP plan to systematically examine the steps in food processing, identify where significant hazards may exist, and decide on the measures that can be put in place to control these risks. Each process step is analyzed for potential hazards - whether chemical, physical, or biological. The table helps operators to determine the significance of each hazard by providing a column for justification. This guides whether a particular step should be identified as a Critical Control Point (CCP) - a point at which control can be applied and is essential to prevent or eliminate a food safety hazard or reduce it to an acceptable level. Preventive measures are then documented along with specifics on monitoring, corrective actions, and record-keeping.

-

What are the Critical Control Points (CCPs) in the ROP HACCP Plan Summary?

CCPs in the ROP (Reduced Oxygen Packaging) HACCP Plan Summary are identified points within the production line that are crucial for preventing, eliminating, or reducing food safety hazards to an acceptable level. The CCPs are determined after a hazard analysis has been performed. For each CCP, the plan outlines the hazard description, critical limits for control measures, monitoring actions specifying what to monitor, how to carry it out, and the frequency of the monitoring. It also stipulates who will be responsible for monitoring and details the corrective actions to be taken in the event the critical limits are not met, alongside verification activities and record-keeping procedures. This part of the HACCP plan is key to ensuring product safety in operations utilizing reduced oxygen packaging methods.

-

What purpose does the Refrigeration/Freezer Log serve?

The Refrigeration/Freezer Log is a monitoring tool used to document the temperatures of cooling units to ensure that food is stored at safe temperatures. With entries for the date, time, temperature reading, and corrective actions taken, this log allows food service workers and managers to keep a timely record of temperature control. The primary purpose of maintaining this log is to verify that all refrigerated or frozen foods are stored in conditions that prevent the growth of harmful bacteria and other pathogens, which can cause foodborne illnesses. Supervisors are tasked with verifying that these temperature checks are carried out correctly by reviewing and initialing the log daily, demonstrating due diligence in maintaining food safety standards.

Common mistakes

When it comes to filling out HACCP (Hazard Analysis Critical Control Points) forms, careful attention to detail is crucial. Making mistakes can lead to significant food safety oversights, risking public health and potentially bringing legal and financial consequences to food establishments. Here are ten common mistakes people often make:

Failing to identify all potential hazards for each processing step. This includes overlooking chemical, physical, or biological hazards that could compromise food safety.

Incorrectly judging the significance of potential food safety hazards. Some might underestimate the risk involved, failing to recognize a hazard's potential impact on consumer health.

Providing inadequate justification for decisions, especially when assessing the significance of hazards. Without clear reasoning, it can be challenging to understand why a decision was made, complicating future reviews or audits.

Not specifying preventive measures clearly or comprehensively. It is essential to outline detailed strategies to mitigate identified risks effectively.

Omitting whether a step is a Critical Control Point (CCP). Identifying CCPs is a core attribute of HACCP planning, directly affecting the control and safety of the food process.

Incomplete documentation in logs, such as the Refrigeration/Freezer Log and Thermometer Calibration Log. Details like date, time, temperature, and corrective actions taken are crucial for effective monitoring and verification.

Incorrect or inconsistent temperature recording, a common error in both the Refrigeration/Freezer Log and Thermometer Calibration Log. This can lead to unsafe food storage or cooking practices.

Neglecting to verify records or sign off on logs. Verification by a supervisor ensures that monitoring and preventive measures are consistently applied.

Forgetting to include product descriptions, lot IDs, or designating a food worker in corrective action logs. Precise details support traceability and accountability in food safety management.

Not maintaining logs for the required period. Records, including relevant actions and verifications, should be kept for at least 90 days after the food has been consumed to allow for adequate backtracking if issues arise.

Avoiding these mistakes requires a thorough understanding of HACCP principles, attention to detail, and a commitment to food safety protocols. By diligently filling out HACCP forms, establishments can better ensure the safety of their food products, protecting both consumers and their business.

Documents used along the form

When it comes to ensuring food safety, the Hazard Analysis and Critical Control Points (HACCP) system is a vital tool for food establishments. This preventive approach aims at identifying, evaluating, and controlling food safety hazards. The HACCP form, which includes a hazard analysis table, an ROP HACCP plan summary, and various logs for refrigeration/freezer temperatures, thermometer calibration, and corrective actions, is an essential document in this system. However, implementing a comprehensive food safety program often requires additional forms and documents. Let's explore some of these important supplementary documents.

- Supplier Verification Forms: These forms are used to ensure that all ingredients sourced from suppliers meet established food safety standards. They typically include information on the supplier's name, address, type of product supplied, and proof of compliance with food safety regulations. This can involve certificates or audit reports that verify the supplier's adherence to HACCP principles or similar food safety protocols.

- Employee Training Records: Training employees in food safety practices is crucial. These records document the training that each employee has received, covering topics such as personal hygiene, cross-contamination prevention, proper cooking temperatures, and cleaning and sanitizing procedures. These records help ensure that all team members are knowledgeable about and capable of implementing food safety practices consistently.

- Equipment Maintenance Logs: Regular maintenance and servicing of kitchen and food processing equipment are critical to prevent contamination and ensure efficient operation. These logs record each piece of equipment's maintenance schedule, including cleaning, servicing, and any repairs done. They also document who performed the maintenance and when it was carried out, thus helping to identify potential sources of food safety issues before they become serious problems.

- Product Testing Records: Many food establishments conduct regular testing of their products for pathogens or spoilage organisms as part of their food safety protocols. These records detail the results of such testing, including the date, the product tested, the tests conducted, and the results. Positive test results often trigger corrective actions to mitigate any identified risks.

- Food Recall Plan: While not a form in the traditional sense, having a documented plan for food recalls is critical. This document outlines the steps to be taken in the event that a product needs to be recalled due to a food safety concern. It includes identifying the recalled product, notifying customers and regulatory authorities, and effectively removing the product from sale. This plan is essential for quickly addressing food safety issues and protecting consumers.

Together with the HACCP forms, these documents form a robust food safety management system that helps food establishments prevent, detect, and respond to food safety hazards. Utilizing these forms and documents effectively can ensure the delivery of safe food products to consumers, thereby maintaining public health and trust in the food industry.

Similar forms

The HACCP form shares similarities with the ISO 22000 Food Safety Management System documentation. Both sets of documents focus on identifying potential hazards, setting critical control points (CCPs), and implementing monitoring procedures to ensure food safety. They require documentation of preventive measures and corrective actions, along with verification and record-keeping procedures, to maintain food safety standards.

Similar to the Standard Operating Procedures (SOPs) used in the food industry, the HACCP form includes detailed procedures for monitoring critical control points, maintaining logs such as the Refrigeration/Freezer Log and the Thermometer Calibration Log, and documenting corrective actions. Both documents serve to standardize operations to ensure consistency and safety in food handling and processing.

The HACCP form also resembles Good Manufacturing Practices (GMP) documentation. Both emphasize the importance of process control, including the identification of hazards and establishment of preventive measures. They are essential for ensuring product safety and quality, requiring detailed record-keeping of processing steps, temperature controls, and corrective actions to comply with regulatory standards.

Quality Assurance/Quality Control (QA/QC) documents in the food industry bear similarities to the HACCP form as well. QA/QC documentation focuses on maintaining high product quality and safety standards through rigorous testing and evaluation procedures. Like the HACCP form, they involve critical analysis of potential hazards, implementation of control measures, and thorough documentation to ensure processes meet defined safety and quality criteria.

Dos and Don'ts

When filling out the HACCP (Hazard Analysis and Critical Control Points) forms, it's important to approach the task with diligence and accuracy. Here are some dos and don'ts to help ensure that the process is carried out correctly:

- Do ensure all information is complete and accurate. Missing or incorrect information can lead to food safety risks not being properly managed.

- Do use clear and specific language to describe each step of the food production process, along with the potential hazards. Ambiguity can lead to misunderstandings and ineffective control measures.

- Do justify your decisions thoroughly in the "Justification of Decision" section. Explaining why a potential food safety hazard is considered significant or not is crucial for the clarity and credibility of your HACCP plan.

- Don't rush through the form. Taking your time to consider each section carefully will help ensure that all potential hazards are properly identified and addressed.

- Don't skip over the temperature logs. Regular and accurate entries in the Refrigeration/Freezer Log and Thermometer Calibration Log are essential for monitoring and maintaining the right conditions to keep food safe.

- Don't forget to regularly review and update the HACCP forms. As operations change or new potential hazards are identified, your HACCP plan should evolve too.

Filling out the HACCP forms attentively and methodically is a vital part of maintaining food safety. By following these dos and don'ts, you can contribute to keeping the food production process safe and compliant with health standards.

Misconceptions

There are several misconceptions about HACCP (Hazard Analysis and Critical Control Points) forms that often lead to confusion. By clarifying these, establishments can better implement food safety practices.

HACCP forms are complicated and time-consuming to fill out: While HACCP forms require detailed information, their structure is designed to streamline the process of identifying and controlling food safety hazards. Once familiar with the form's layout and requirements, food establishments find them straightforward and integral to routine operations.

Only large food establishments need HACCP plans: Regardless of size, all food operations that handle and serve food can benefit from implementing a HACCP plan. It helps in identifying potential food safety hazards and establishing controls to ensure food safety, which is critical for all, not just large, establishments.

HACCP is only about documenting processes and not practical safety measures: While documentation is a significant part of HACCP, the primary goal is to ensure food safety through practical measures. The documentation supports the process by ensuring consistency and accountability in following through with safety measures.

Once a HACCP plan is set, no further changes are required: Food safety environments are dynamic, and a HACCP plan must be reviewed and updated regularly to reflect changes in processes, equipment, or regulations. Continuous improvement and updates are essential parts of maintaining an effective HACCP plan.

All steps in a food process are Critical Control Points (CCPs): Not all steps in a food production process are CCPs. A CCP is a point where control can be applied to prevent, eliminate, or reduce food safety hazards to acceptable levels. Identifying CCPs is a critical aspect of the HACCP plan, focusing efforts where they are most needed.

Implementing HACCP will guarantee no food safety issues: While HACCP significantly reduces the risk of food safety hazards, it cannot guarantee that there will never be food safety issues. Vigilance, regular training, and updates to the HACCP plan are necessary to maintain high standards of food safety.

Understanding these misconceptions can help food establishments effectively implement HACCP plans and ensure food safety. Consistent training, vigilance, and adherence to the HACCP principles are critical to its success.

Key takeaways

When managing food safety through the Hazard Analysis Critical Control Point (HACCP) system, it's essential to utilize and properly fill out HACCP forms and flow charts. Here are key takeaways to ensure you're effectively using these tools to promote food safety:

- Understanding the Hazard Analysis Table is crucial. This section helps in identifying potential chemical, physical, and biological hazards at each processing step, assessing their significance, and determining preventive measures and whether the step is a Critical Control Point (CCP).

- It's important to clearly document the name of the food establishment, address, and a brief product description at the beginning of the forms to ensure proper identification and accountability.

- The signature and date sections at the bottom of the forms must be completed to validate the information provided and to demonstrate compliance with food safety requirements.

- The ROP HACCP Plan Summary outlines the critical elements of the HACCP plan, including CCPs, hazard descriptions, critical limits, monitoring procedures, corrective actions, verification activities, and record-keeping practices.

- Maintaining Refrigeration/Freezer Logs is essential for tracking the temperature of food storage units to prevent the growth of harmful bacteria and ensure food safety. This log includes columns for the location/description of the unit, date, time, temperature, corrective action taken, and initials of the food worker and manager.

- The Thermometer Calibration Log is a critical tool for ensuring the accuracy of thermometers used in the establishment. It involves recording the thermometer ID, calibration temperature, adjustments required, corrective actions taken, and verification by a supervisor.

- Corrective Action Logs are vital for documenting any deviations from critical limits at CCPs. This log helps in identifying the cause of deviation, corrective actions taken to eliminate the cause, and measures to prevent recurrence. It also includes information on product disposition and verification by a supervisor.

- Regular verification by a supervisor, through visual monitoring and review of logs, is essential for ensuring that foodservice employees are adhering to food safety practices and that the HACCP plan is being effectively implemented.

- All HACCP related logs should be maintained for a minimum of 90 days after the food has been consumed to allow for adequate record review in case of food safety audits or inspections.

Properly completing and utilizing HACCP forms and logs is a key part of maintaining food safety management processes within food establishments. By adhering to these guidelines, establishments can help prevent foodborne illnesses and ensure the integrity of their food safety efforts.

Popular PDF Forms

Rental Application Form Maryland - Applicants are required to provide data about their current living situation, such as landlord contact details and reasons for moving, offering insight into their rental history.

Subpoena Form - A legally sanctioned order from Maryland requiring one’s contribution to judicial proceedings through presence or evidence.