Blank Haccp Plan Oyster PDF Template

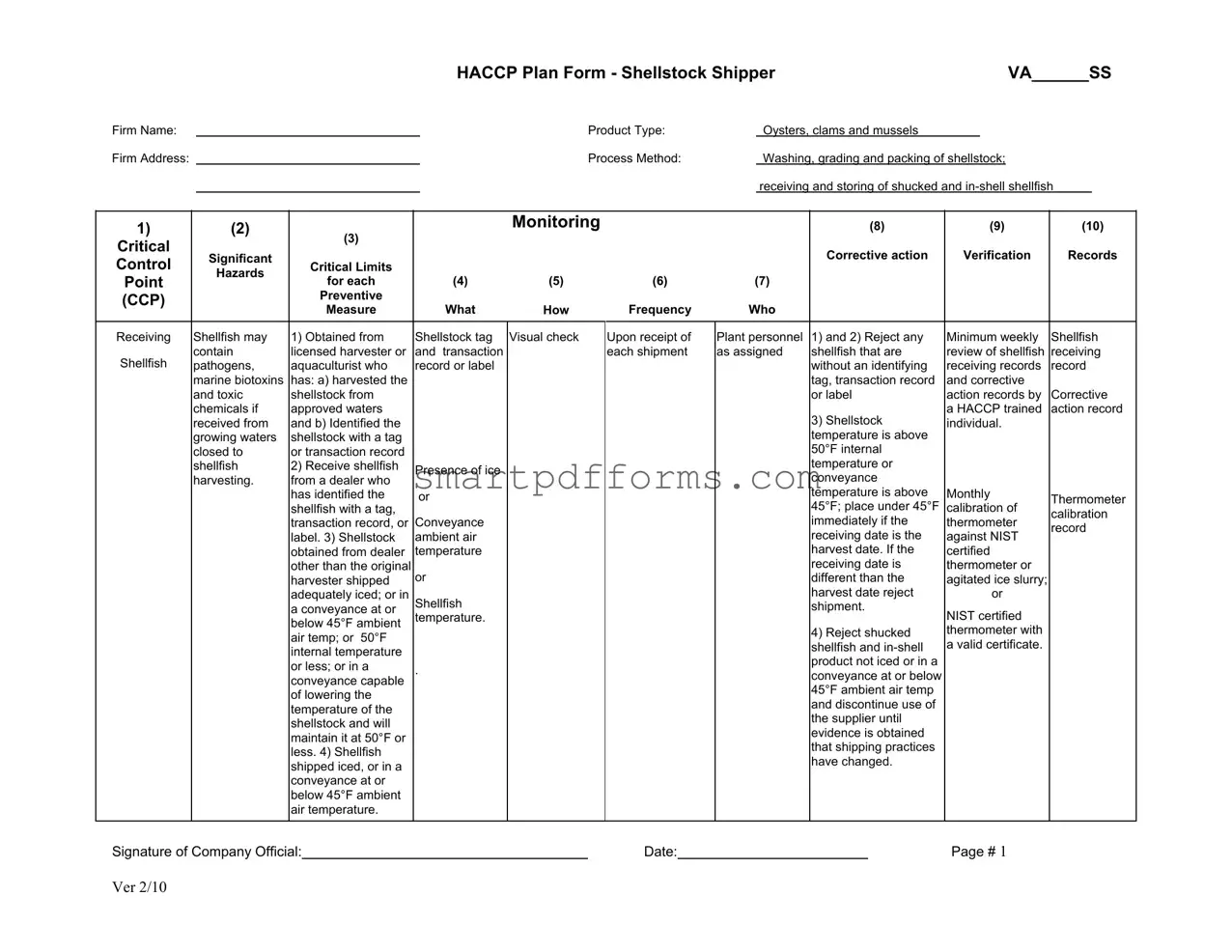

In the highly regulated seafood industry, maintaining the safety and quality of products like oysters, clams, and mussels is paramount. The Hazard Analysis Critical Control Point (HACCP) Plan Form for Shellstock Shippers, specifically designed for Virginia, represents a comprehensive framework ensuring these standards are met. It delineates specific procedures for handling, washing, grading, packing, receiving, and storing shellfish, aligned with critical checkpoints to mitigate risks associated with pathogens, marine biotoxins, and chemical contaminants. Key elements encompass the sourcing from licensed harvesters or aquaculturists, ensuring shellfish are tagged or labeled correctly, meeting specific temperature controls during storage and transit, and establishing protocols for the visual inspection upon receipt. Monitoring frequency, calibration of instruments, and corrective actions form the procedural backbone, ensuring continuous adherence to safety protocols. By prioritizing such measures, the form sets a stringent guideline to prevent the distribution of contaminated shellfish, protect consumer health, and uphold the industry's integrity.

Preview - Haccp Plan Oyster Form

|

|

|

|

|

|

HACCP Plan Form - Shellstock Shipper |

|

|

|

VA______SS |

||||||||

Firm Name: |

|

|

|

|

|

|

|

Product Type: |

|

Oysters, clams and mussels |

|

|

|

|

||||

Firm Address: |

|

|

|

|

|

|

|

Process Method: |

|

Washing, grading and packing of shellstock; |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

receiving and storing of shucked and |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

1) |

(2) |

|

|

|

|

Monitoring |

|

|

(8) |

(9) |

(10) |

|||||||

(3) |

|

|

|

|

|

|

|

|

||||||||||

Critical |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Significant |

|

|

|

|

|

|

|

|

|

|

Corrective action |

Verification |

Records |

||||

Control |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

Critical Limits |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Hazards |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Point |

|

|

for each |

(4) |

(5) |

(6) |

|

(7) |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|||||||||

(CCP) |

|

|

|

Preventive |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Measure |

|

What |

How |

|

Frequency |

Who |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||

Receiving |

Shellfish may |

1) Obtained from |

Shellstock tag |

Visual check |

|

Upon receipt of |

Plant personnel |

1) and 2) Reject any |

Minimum weekly |

Shellfish |

||||||||

|

contain |

licensed harvester or |

and transaction |

|

|

each shipment |

as assigned |

shellfish that are |

review of shellfish |

receiving |

||||||||

Shellfish |

pathogens, |

aquaculturist who |

record or label |

|

|

|

|

|

|

without an identifying |

receiving records |

record |

||||||

|

marine biotoxins |

has: a) harvested the |

|

|

|

|

|

|

|

|

tag, transaction record |

and corrective |

|

|

||||

|

and toxic |

shellstock from |

|

|

|

|

|

|

|

|

or label |

action records by |

Corrective |

|||||

|

chemicals if |

approved waters |

|

|

|

|

|

|

|

|

|

|

a HACCP trained |

action record |

||||

|

received from |

and b) Identified the |

|

|

|

|

|

|

|

|

3) Shellstock |

individual. |

|

|

||||

|

growing waters |

shellstock with a tag |

|

|

|

|

|

|

|

|

temperature is above |

|

|

|

|

|||

|

closed to |

or transaction record |

|

|

|

|

|

|

|

|

50°F internal |

|

|

|

|

|||

|

shellfish |

2) Receive shellfish |

Presence of ice |

|

|

|

|

|

|

temperature or |

|

|

|

|

||||

|

|

|

|

|

|

|

conveyance |

|

|

|

|

|||||||

|

harvesting. |

from a dealer who |

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

has identified the |

or |

|

|

|

|

|

|

temperature is above |

Monthly |

Thermometer |

|||||

|

|

|

shellfish with a tag, |

|

|

|

|

|

|

|

|

45°F; place under 45°F |

calibration of |

|||||

|

|

|

|

|

|

|

|

|

|

|

calibration |

|||||||

|

|

|

transaction record, or |

Conveyance |

|

|

|

|

|

|

immediately if the |

thermometer |

||||||

|

|

|

|

|

|

|

|

|

record |

|||||||||

|

|

|

label. 3) Shellstock |

ambient air |

|

|

|

|

|

|

receiving date is the |

against NIST |

||||||

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

obtained from dealer |

temperature |

|

|

|

|

|

|

harvest date. If the |

certified |

|

|

||||

|

|

|

other than the original |

or |

|

|

|

|

|

|

receiving date is |

thermometer or |

|

|

||||

|

|

|

harvester shipped |

|

|

|

|

|

|

different than the |

agitated ice slurry; |

|

|

|||||

|

|

|

adequately iced; or in |

Shellfish |

|

|

|

|

|

|

harvest date reject |

|

or |

|

|

|||

|

|

|

|

|

|

|

|

|

shipment. |

|

|

|

||||||

|

|

|

a conveyance at or |

temperature. |

|

|

|

|

|

|

NIST certified |

|

|

|||||

|

|

|

below 45°F ambient |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

4) Reject shucked |

thermometer with |

|

|

||||||

|

|

|

air temp; or 50°F |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

shellfish and |

a valid certificate. |

|

|

||||

|

|

|

internal temperature |

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

product not iced or in a |

|

|

|

|

|||

|

|

|

or less; or in a |

. |

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

conveyance at or below |

|

|

|

|

||||

|

|

|

conveyance capable |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

45°F ambient air temp |

|

|

|

|

|||

|

|

|

of lowering the |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

and discontinue use of |

|

|

|

|

|||

|

|

|

temperature of the |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

the supplier until |

|

|

|

|

|||

|

|

|

shellstock and will |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

evidence is obtained |

|

|

|

|

|||

|

|

|

maintain it at 50°F or |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

that shipping practices |

|

|

|

|

|||

|

|

|

less. 4) Shellfish |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

have changed. |

|

|

|

|

|||

|

|

|

shipped iced, or in a |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

conveyance at or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

below 45°F ambient |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

air temperature. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

Signature of Company Official: |

|

|

|

|

Date: |

|

|

|

|

Page # 1 |

|

|

||||||

VER 2/10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HACCP Plan Form - Shellstock Shipper |

|

VA______SS |

||||||||

Firm Name: |

|

|

|

|

|

Product Type: |

|

|

Oysters, clams and mussels |

|

|

|

|

||

Firm Address: |

|

|

|

Process Method: |

|

|

Washing, grading and packing of shellstock; |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

receiving and storing of shucked and |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

(1) |

(2) |

|

|

|

Monitoring |

|

|

|

|

(8) |

(9) |

(10) |

|||

(3) |

|

|

|

|

|

|

|

|

|

|

|

|

|||

Critical |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Significant |

|

|

|

|

|

|

|

|

Corrective action |

Verification |

Records |

|||

Control |

|

|

|

|

|

|

|

|

|

||||||

|

Critical Limits |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Hazards |

|

|

|

|

|

|

|

|

|

|

|

|

||

Point |

|

for each |

(4) |

(5) |

(6) |

(7) |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|||||||||

(CCP) |

|

|

Preventive |

|

|

|

Frequency |

Who |

|

|

|

|

|

|

|

|

|

|

Measure |

|

What |

How |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|||||

Shellstock |

Growth of |

Once under |

Time out of |

Record duration |

For every lot |

Plant personnel |

If the shellstock are out |

Minimum weekly |

Shellstock |

||||||

|

pathogenic |

temperature |

of time |

or pallet. |

as assigned. |

|

of temperature control |

review of shellstock |

|||||||

|

temperature control, |

|

temperature control |

||||||||||||

Points of |

bacteria |

control. |

shellstock |

|

|

|

|

||||||||

transfer/loading |

|

|

shellstock not |

|

|

outside of |

|

|

|

|

for more than 2 hours |

transfer records |

record |

||

|

|

|

|

|

|

|

|

then check internal |

and corrective |

||||||

dock |

|

|

permitted to remain |

|

|

temperature |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

temperature. |

action records by a |

|

|

||||

|

|

|

outside of |

|

|

control. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

HACCP trained |

Thermometer |

||||

|

|

|

refrigeration for more |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

If the shellstock |

individual. |

calibration record |

|||

|

|

|

than 2 hours at |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

temperature is >50°F, |

|

|

|

|

|

|

|

|

loading dock. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

the product will be iced |

Monthly calibration |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Corrective action |

||||

|

|

|

|

|

|

|

|

|

|

|

or chilled as rapidly as |

of thermometer |

record |

||

|

|

|

|

|

|

|

|

|

|

|

practicable to bring the |

against NIST |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

internal temperature to |

certified |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50°F. |

thermometer or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

agitated ice slurry; |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NIST certified |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

thermometer with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

valid certificate. |

|

|

|

Signature of Company Official: |

|

Date: |

|

Page # 2 |

VER 2/10

|

|

|

|

|

|

HACCP Plan Form - Shellstock Shipper |

|

VA______SS |

||||||

Firm Name: |

|

|

|

|

|

Product Type: |

|

Oysters, clams and mussels |

|

|

|

|

||

Firm Address: |

|

|

|

|

Process Method: |

|

Washing, grading and packing of shellstock; |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

receiving and storing of shucked and |

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|||

(1) |

(2) |

|

|

|

Monitoring |

|

|

(8) |

(9) |

(10) |

||||

(3) |

|

|

|

|

|

|

|

|

|

|

|

|||

Critical |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Significant |

|

|

|

|

|

|

|

Corrective action |

Verification |

Records |

||||

Control |

|

|

|

|

|

|

|

|||||||

Critical Limits |

|

|

|

|

|

|

|

|

|

|

|

|||

Point |

Hazards |

for each |

(4) |

|

(5) |

(6) |

(7) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

(CCP) |

|

|

Preventive |

|

|

|

Frequency |

Who |

|

|

|

|

|

|

|

|

|

Measure |

What |

How |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

Shellfish |

Growth of |

Shellfish must be: |

a) Presence of |

a) Visual check |

Minimum of |

Plant |

|

|

Minimum weekly |

Shellfish |

||||

pathogenic |

|

ice; or |

for presence of |

2 times per |

personnel |

If ice is not present and the shucked |

review of shellfish |

storage |

||||||

storage |

|

|||||||||||||

bacteria |

a) Iced; or |

|

|

adequate ice; or |

day |

as assigned |

shellfish temperature is between 45°F - |

storage area records |

temperature |

|||||

|

|

|

||||||||||||

|

|

|

|

b) Shellfish |

|

|

|

50°F, the shellfish will be iced or chilled as |

and corrective action |

record |

||||

|

|

|

b) Stored in a |

cooler |

b) Record |

|

|

rapidly as practicable to bring the internal |

records by a HACCP |

|

|

|||

|

|

|

storage area or |

temperature |

shellfish cooler |

|

|

temperature to 45°F. |

trained individual. |

Thermometer |

||||

|

|

|

conveyance |

|

|

temperatures |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

calibration |

|||

|

|

|

maintained at 45°F |

|

|

|

|

|

If the cooler temperature is >45°F and the |

Monthly calibration |

||||

|

|

|

(7.2°C) or less |

|

|

|

|

|

shellstock temperature is >50°F, the |

of thermometer |

record |

|||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

shellstock will be iced or chilled as rapidly |

against NIST |

|

|

||

|

|

|

|

|

|

|

|

|

as practicable to bring the internal |

certified |

Corrective |

|||

|

|

|

|

|

|

|

|

|

temperature to 50°F. |

thermometer or |

||||

|

|

|

|

|

|

|

|

|

action record |

|||||

|

|

|

|

|

|

|

|

|

|

|

agitated ice slurry; |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

or |

|

|

|

|

|

|

|

|

|

|

|

|

|

NIST certified |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

thermometer with |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

valid certificate. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Signature of Company Official: |

|

Date: |

|

Page # 3 |

VER 2/10

Form Data

| Fact | Detail |

|---|---|

| Form Purpose | HACCP Plan Form for Shellstock Shippers with a focus on safety in handling oysters, clams, and mussels. |

| Product Type | Covers oysters, clams, and mussels. |

| Process Method | Includes washing, grading, and packing of shellstock; and receiving and storing of shucked and in-shell shellfish. |

| Monitoring and Verification | Establishes procedures for monitoring critical control points, verification activities, and record-keeping. |

| Corrective Actions | Specifies corrective actions for non-compliance at various control points to ensure safety. |

| Records and Documentation | Requires detailed records for critical limits, verification, and corrective actions. |

| Temperature Control | Emphasizes strict temperature control for receiving, storing, and transporting shellfish to prevent bacterial growth. |

| Governing Law(s) | Although the form is specifically designed for Virginia ('VA______SS'), practices should adhere to both state and federal food safety regulations. |

Instructions on Utilizing Haccp Plan Oyster

Filling out the HACCP Plan Oyster form requires attention to detail and a clear understanding of the required steps to ensure the safety and quality of shellfish products. By accurately completing this form, firms can demonstrate their commitment to monitoring and managing potential hazards in the processing and transportation of oysters, clams, and mussels. The following steps will guide you through the necessary information and actions required to complete the form effectively.

- Start by entering the specific identification details at the top of the form, including the VA______SS Firm Name, the Type of Product (Oysters, clams, and mussels), the Firm Address, and the Process Method employed, such as washing, grading, and packing of shellstock; receiving and storing of shucked and in-shell shellfish.

- Under the Critical Control Point (CCP) for receiving shellfish, ensure all shellfish received is from a licensed harvester or aquaculturist who has harvested the shellstock from approved waters and identified it with a tag or transaction record.

- For each Significant Hazard identified, such as pathogens, marine biotoxins, and toxic chemicals, document the Preventive Measure, including receiving shellstock only from approved sources and ensuring shellstock temperature compliance upon receipt.

- Detail the Monitoring actions to be taken, specifying what is checked (e.g., shellstock tags, temperature), how it is checked (e.g., visual inspection, thermometer), the frequency of checks (e.g., upon receipt, minimum weekly), and who is responsible for the verification process.

- Outline the Corrective Actions to take if critical limits are exceeded. This might include rejecting shellfish that do not meet the established criteria or taking steps to rapidly chill products that exceed temperature thresholds.

- Describe the Verification measures to ensure that the HACCP plan is functioning correctly. This might involve review of shellfish receiving records and corrective action records by a HACCP-trained individual.

- Document the Records that will be maintained, including receiving records, corrective action records, and thermometer calibration records, to demonstrate compliance with the HACCP plan.

- Complete the form by having a Company Official sign and date it at the bottom of each page, verifying the accuracy and commitment to the HACCP plan outlined.

Upon completion, the form serves as a comprehensive record of the measures taken to ensure the safety and quality of oysters, clams, and mussels from receiving through processing and storage. It is vital to regularly review and update this document as necessary to incorporate any changes in processing methods, regulatory requirements, or identified hazards.

Obtain Answers on Haccp Plan Oyster

What is the purpose of the HACCP Plan Oyster form?

The HACCP (Hazard Analysis Critical Control Point) Plan Oyster form is used to establish a detailed plan for safely processing, receiving, storing, and handling oysters, clams, and mussels. Its primary objective is to identify potential hazards—biological, chemical, and physical—that could contaminate these shellfish and outline the procedures for minimizing or eliminating these risks.

Who needs to complete the HACCP Plan Oyster form?

Any firm involved in the washing, grading, packing, receiving, and storing of shucked and in-shell shellfish such as oysters, clams, and mussels must complete this form. It ensures that the business adheres to food safety standards and practices necessary to safeguard the health of the consumers and the firm's reputation.

What are Critical Control Points (CCPs) in the context of this form?

Critical Control Points (CCPs) are stages in the process where control can be applied to prevent, eliminate, or reduce significant hazards to a safe level. In the context of the HACCP Plan Oyster form, CCPs might include processes like receiving shellfish, ensuring proper shellstock temperature, and maintaining the correct storage temperatures.

How often should visual checks and temperature measurements be performed?

Visual checks of the shellstock and transaction records or labels should be done upon the receipt of each shipment. Shellstock temperatures need to be monitored at least weekly, while specific checks such as ensuring shellfish are iced or stored at the correct temperature should occur a minimum of two times per day or whenever shellstock is received.

What should be done if shellfish are received without proper identification?

If shellfish are received without an identifying tag, transaction record, or label, the shellfish must be rejected. It's essential for traceability and ensures the shellfish come from approved and safe sources.

What steps should be taken if shellfish or shellstock are found above their critical temperature limit?

If shellfish or shellstock exceed their critical temperature limit—45°F for shellfish in conveyance or 50°F for internal shellstock temperature—they should be immediately placed under adequate ice or in a cooler to lower the temperature. If the issue pertains to the cooler's or conveyance's temperature during receiving or storage, corrective actions include icing, chilling as rapidly as possible to bring the temperature down to 50°F or below, or discontinuation of use of the supplier until shipping practices have changed.

How should corrective actions be recorded and verified?

Corrective actions must be documented in corrective action records by individuals trained in HACCP. These records should detail the issue encountered, the specific corrective action taken, and the result of the action. Verification of these actions typically involves reviewing temperature logs, thermometer calibration records, and ensuring that the corrective measures are effective in preventing recurrence of the problem.

Who is responsible for monitoring and ensuring compliance with the HACCP plan?

Plant personnel trained in HACCP principles are assigned the responsibility of monitoring critical control points, performing visual checks, temperature measurements, and any necessary corrective actions. Moreover, a company official is required to sign the HACCP Plan Oyster form, indicating the firm's commitment to comply with the established food safety measures.

What happens if the HACCP plan is not properly followed?

If the HACCP plan is not properly followed, it could lead to the shipment of unsafe shellfish, which poses serious health risks to consumers. Such negligence can result in regulatory actions against the firm, including fines, seizure of products, and closure of facilities. It also damages the firm’s reputation and trust with consumers and partners.

Common mistakes

Completing the Hazard Analysis Critical Control Point (HACCP) Plan, especially for oyster operations, is a complex process that requires detail-oriented attention. Given the health risks associated with improperly handled shellfish, it is crucial for shellstock shippers to avoid common mistakes. Here, eight such mistakes are discussed, which can significantly impact the safety and compliance of the operations.

Not properly identifying the source of shellfish: When shellfish are received, it is essential that they come from a licensed harvester or aquaculturist who has harvested the shellstock from approved waters. Failing to verify and document this information can undermine the entire safety protocol,

Omitting critical temperature checks upon receipt: Shellfish must be checked to ensure their internal temperature is at or below 50°F upon arrival. Skipping this step can lead to the acceptance of potentially unsafe shellfish,

Inadequate monitoring of storage conditions: Both the ambient air temperature of the storage area and the internal temperature of shellfish must be regularly monitored and logged. Ignoring these parameters can result in shellfish being stored in conditions conducive to the growth of pathogens,

Failure to reject improperly tagged shellfish: Any shellfish received without a proper shellstock tag, transaction record, or label must be rejected. Overlooking this control measure can introduce significant health risks,

Neglecting to verify the thermometer's accuracy: The thermometer used for measuring shellfish and storage temperatures must be calibrated against a NIST (National Institute of Standards and Technology) certified thermometer. Failure to ensure thermometer accuracy can result in inappropriate temperature controls,

Poor handling of shellfish at critical control points: Critical limits, such as specific temperatures and handling processes, are set at each critical control point (CCP) to mitigate hazards. Failing to adhere to these limits can compromise the safety of the shellfish,

Insufficient corrective actions: Whenever a deviation from a critical limit occurs, appropriate corrective actions must be taken immediately. Insufficient corrective measures or documentation can allow unsafe products to enter the marketplace,

Inadequate training of personnel: The effectiveness of the HACCP plan heavily relies on the proper training of personnel involved in monitoring, verification, and corrective actions. Lack of adequate training can lead to oversights and mismanagement of critical control points.

Addressing these common mistakes requires diligent oversight and a commitment to the protocols established within the HACCP plan. Proper implementation of these measures not only ensures compliance with health regulations but significantly minimizes the risk of foodborne illnesses associated with shellfish.

Documents used along the form

When managing seafood safety, especially for oysters, clams, and mussels, a HACCP (Hazard Analysis Critical Control Point) Plan is foundational. However, it is not the only document that businesses in the seafood supply chain should maintain. Several other forms and documents often accompany the HACCP Plan to ensure compliance with regulatory requirements and to enhance food safety practices. These documents play a crucial role in the preventive framework designed to address biological, chemical, and physical hazards associated with seafood products.

- Standard Operating Procedures (SOPs): These are detailed written instructions designed to achieve uniformity in the performance of a specific function. SOPs often accompany a HACCP Plan to provide guidance on how to perform tasks or processes that are critical to maintaining seafood safety. For example, an SOP for the cleaning and sanitation of processing equipment can help prevent the contamination of oysters during processing.

- Supplier Verification Records: These records are crucial for businesses that receive seafood from various suppliers. They document the verification of a supplier’s compliance with food safety standards, including their HACCP Plans and practices. Such records help ensure that all incoming raw materials, like shellstock, meet the safety criteria established in the recipient's HACCP Plan.

- Training Records: Food safety regulations often require individuals handling and processing seafood to receive proper training in food safety principles, including HACCP. Training records document the content and attendees of these training sessions, ensuring that all personnel are adequately trained to execute their roles within the HACCP framework effectively.

- Cooling Logs: Since temperature control is a critical factor in seafood safety, cooling logs are used to document the temperatures of seafood products over time. These logs are essential for verifying that products like oysters are stored and transported at safe temperatures, as specified in the HACCP Plan’s critical limits for temperature control.

In summary, a HACCP Plan is a critical component of seafood safety management, particularly for oysters, clams, and mussels. However, supplementary documents such as SOPs, supplier verification records, training records, and cooling logs are equally vital. Together, these documents create a comprehensive food safety system that helps prevent product contamination and ensures the delivery of safe, high-quality seafood to consumers.

Similar forms

Food Safety Plan Forms: The HACCP Plan Oyster form closely aligns with various food safety plan forms across the food industry. These documents, like the HACCP Plan, establish procedures for managing critical control points to prevent foodborne illnesses. They detail monitoring procedures, critical limits, verification activities, and corrective actions, specifically tailored to different food products like meats, poultry, or dairy products.

Seafood Import Monitoring Program (SIMP) Records: Similar to the HACCP Plan Oyster form, SIMP records require detailed documentation to ensure that imported seafood complies with U.S. food safety regulations. Both documents necessitate traceability, including harvest and processing information, to guarantee that seafood is safe, legally caught, and sourced from sustainable practices.

Standard Operating Procedures (SOPs) for Food Manufacturing: SOPs in the food manufacturing sector share similarities with the HACCP Plan Oyster form in their structured approach to food safety. Both documents outline specific procedures to control and prevent the risk of contamination at critical points during the food production and handling processes.

Quality Assurance (QA) Manuals: QA manuals for food processing plants are closely related to the HACCP Plan Oyster form, as both documents emphasize the importance of quality control measures throughout the production process. They focus on ensuring products meet defined safety standards and are free from contaminants through rigorous testing and monitoring.

Food Recall Plans: Food recall plans are similar to the HACCP Plan Oyster form in that they both include protocols for addressing safety concerns. While the HACCP Plan focuses on prevention, food recall plans provide a framework for responding to potential risks, including how to trace and remove tainted products from the market efficiently.

Good Manufacturing Practices (GMP) Documentation: GMP documentation and the HACCP Plan Oyster form share objectives in maintaining food safety and quality. Both sets of documents guide facilities on best practices, from personal hygiene to equipment maintenance, to minimize risks of contamination during food processing.

Traceability and Compliance Records for Organic Certification: Similar to the HACCP Plan Oyster form, these records are crucial for verifying compliance with organic standards. Both document types require detailed tracking of the product through every stage of the supply chain to ensure adherence to specified regulations and standards, albeit for different purposes – safety in the case of HACCP, and organic integrity for certification.

Dos and Don'ts

When filling out the HACCP Plan for Oyster form, certain practices should be followed to ensure accuracy, compliance, and safety. Below is a list of the things you should and shouldn't do:

Do:- Ensure all information provided is accurate and up to date, including the firm name, address, and the specifics of the process method described.

- Verify that shellfish are received from licensed harvesters or aquaculturists who meet all requirements, such as harvesting from approved waters.

- Conduct visual checks and review transaction records or labels upon receiving each shipment of shellfish to ensure compliance with critical limits.

- Reject any shellfish that do not have proper identification, such as a tag or transaction record, immediately upon receipt.

- Maintain and monitor shellfish storage temperatures rigorously, ensuring they meet the specified critical limits for safety.

- Use a NIST certified thermometer for temperature verifications to ensure accuracy.

- Review and update receiving and storage records weekly as part of monitoring and verification procedures.

- Take corrective action immediately if any deviations from critical limits occur, and record these actions accordingly.

- Ensure all plant personnel involved in handling and verifying shellfish shipments are trained in HACCP protocols.

- Perform monthly calibrations of your thermometers against NIST certified standards to ensure continued accuracy.

- Accept shellfish without verifying they come from approved sources and are properly tagged or labeled.

- Ignore temperature control requirements; failing to maintain the proper temperature could lead to pathogen growth.

- Overlook the importance of immediate corrective actions when a deviation occurs. Delay can compromise shellfish safety.

- Use uncalibrated or inaccurate thermometers for verification activities.

- Fail to maintain and regularly review records of shellfish receiving, storage, and corrective actions taken.

- Receive shellfish if the supplier has previously sent shipments that fail to meet critical limits until they provide evidence of compliant shipping practices.

- Disregard the requirement for shellfish to be iced or stored in cool temperatures immediately upon receiving to prevent pathogen growth.

- Miss conducting a minimum weekly review of receiving records and corrective action records, which ensures ongoing compliance.

- Receive shellfish from dealers who do not provide complete documentation of harvest areas and conditions.

- Fail to sign the HACCP Plan document, as the signature of a company official is mandatory for verification.

Misconceptions

When it comes to HACCP (Hazard Analysis Critical Control Point) Plans, particularly for oysters, misunderstanding the requirements and processes can lead to mismanagement of food safety risks. Here are nine common misconceptions about the HACCP Plan Oyster form and the truths behind them:

Only the presence of pathogens is a concern: While pathogens are a critical concern in oyster safety, the HACCP plan also addresses marine biotoxins and toxic chemicals, underscoring the multi-faceted approach required for comprehensive food safety.

Visual checks are sufficient for receiving shellfish: Though visual checks of shellstock tags and labels are essential, they must be accompanied by temperature checks and verification that shellfish come from approved waters, demonstrating the layered safety measures in place.

Temperature requirements are overemphasized: The strict temperature controls detailed in the plan, such as ensuring shellfish are stored at or below 45°F, are fundamental in inhibiting the growth of pathogenic bacteria and ensuring the safety of the shellfish.

Once received, shellfish management is no longer critical: Every step, from receiving to storage, is critical. The plan outlines specific conditions, such as maintaining shellfish in adequately iced conditions, to prevent food safety hazards throughout the distribution chain.

Supplier verification is a one-time process: Continual verification of suppliers, including ensuring shellfish are harvested from approved waters and maintaining the correct shipping temperature, is mandatory, indicating that supplier validation is an ongoing requirement.

Any ice is adequate for cooling: The presence of ice alone is not enough. Shellfish must be iced or stored in conditions that guarantee the internal temperature is maintained at or below specific limits, illustrating the precise requirements for ice as a cooling medium.

Corrective actions are only taken when pathogens are detected: Corrective actions are also required for temperature abuses or when shellfish do not come from approved sources, showcasing the proactive approach in managing potential food safety issues.

HACCP plans are static: They require regular reviews, including weekly and monthly checks, and adjustments as necessary based on temperature calibration records and corrective action records. This continuous improvement process ensures the plan remains effective.

Regulation compliance is the sole goal of HACCP plans: While meeting regulatory requirements is important, the ultimate goal is to protect public health by ensuring the safety of food products, in this case, shellfish.

Understanding these aspects clearly helps in implementing effective food safety practices in the oyster industry, ultimately ensuring the well-being of consumers and compliance with relevant food safety standards.

Key takeaways

When filling out and using the HACCP Plan Oyster form, there are important considerations to ensure the safety and quality of shellfish products. Here are key takeaways:

- Ensure all shellfish, specifically oysters, clams, and mussels, come from a licensed harvester or aquaculturist who has harvested the shellstock from approved waters and has correctly identified the growing waters.

- Each shipment of shellfish must be received with a shellstock tag, transaction record, or label to verify its source and ensure traceability.

- Visual checks upon receipt of each shellfish shipment are crucial, with a minimum weekly review of shellfish receiving and corrective action records by a HACCP trained individual.

- Reject any shellfish that do not have an identifying tag or transaction record or those that show signs of pathogen contamination, marine biotoxins, or toxic chemicals.

- Monitor and document the temperature of shellfish upon reception. Shellstock temperature should not exceed 50°F internally, and the ambient air temperature of the conveyance should be at or below 45°F.

- Monthly calibration of thermometers against a NIST certified thermometer is required to ensure accurate temperature measurements.

- If shellfish are out of temperature control for more than 2 hours at the loading dock, they must not be permitted to remain outside of refrigeration. Actions should be taken to ice or chill the shellfish as rapidly as practicable to bring the internal temperature to 50°F.

- Storage conditions for shellfish must adhere to strict temperature guidelines; shellfish must be iced or stored in a cooler/conveyance maintained at 45°F (7.2°C) or less to inhibit the growth of pathogenic bacteria.

- Documenting the presence of ice or adequate refrigeration for shellfish storage twice per day is a preventive measure against bacterial growth.

- The HACCP Plan Oyster form must be signed by a company official to validate the adherence to safety protocols, with defined corrective actions for any identified issues.

Following these guidelines ensures the safe handling, storage, and transportation of shellfish, protecting consumers from foodborne illnesses and supporting regulatory compliance.

Popular PDF Forms

Kuehne Nagel Eei - Facilitates compliance with destination control statement requirements, necessary for certain exports regulated by the Department of Commerce or the State Department.

School Referral - Student partook in truancy, absent from school without permission and without notifying office.

Pa100 Form - If your business is reactivating previous tax or service accounts, you'll need to complete the PA-100 form.