Blank Hvac Inspection Checklist PDF Template

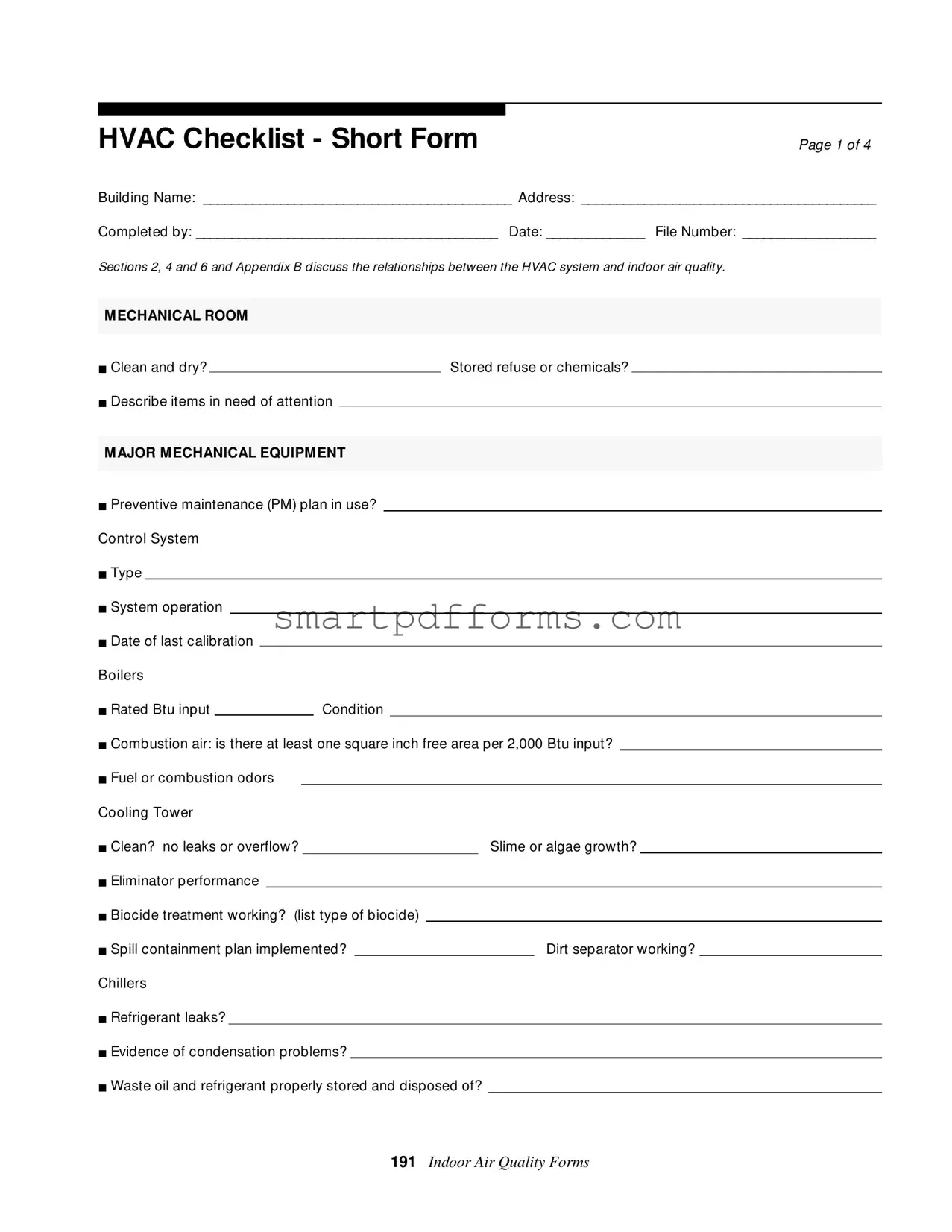

An HVAC inspection checklist form serves as a comprehensive guide for examining the various components that ensure the heating, ventilation, and air conditioning (HVAC) system in a building operates efficiently and effectively. This particular form spans four detailed pages, starting with basic building information, and dives into in-depth evaluations of the mechanical room, major mechanical equipment like boilers, chillers, and the cooling tower, as well as the air handling units. Each section underscores the importance of regular preventative maintenance and identifies specific areas that may require immediate attention, such as cleanliness, leaks, operational controls, and potential safety hazards. The checklist further explores the distribution system, scrutinizing the condition and functionality of supply and return air pathways, and assessing the adequacy of air filters. Occupied space analysis is also covered, examining thermostat operations and potential problems that could affect indoor comfort and air quality. By meticulously following this checklist, building managers can ensure their HVAC systems contribute to a safe and comfortable indoor environment, underlining the intricate relationship between HVAC performance and indoor air quality.

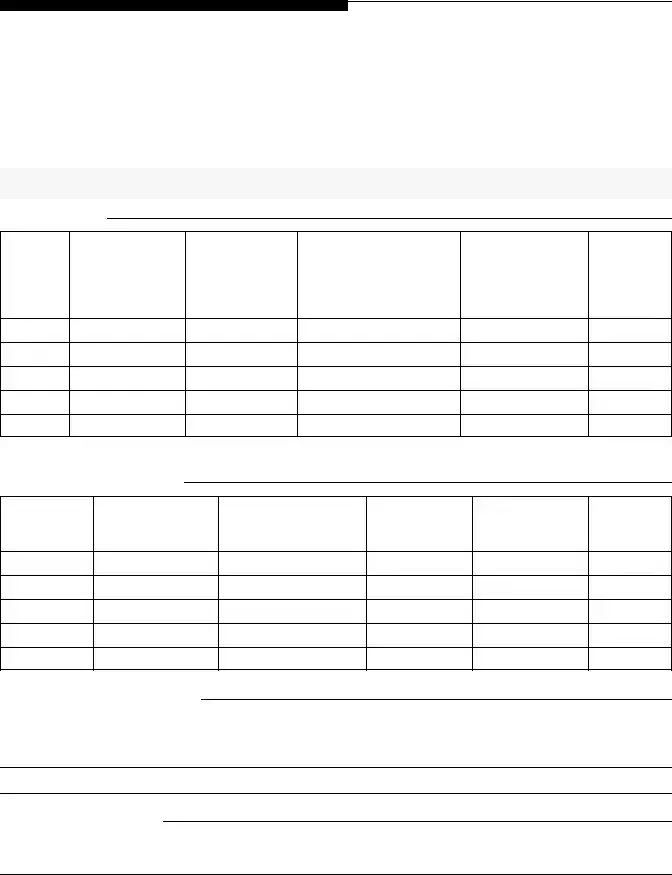

Preview - Hvac Inspection Checklist Form

HVAC CHECKLIST - SHORT FORM

Page 1 of 4

Building Name: ____________________________________________ Address: __________________________________________

Completed by: ___________________________________________ Date: ______________ File Number: ___________________

Sections 2, 4 and 6 and Appendix B discuss the relationships between the HVAC system and indoor air quality.

MECHANICAL ROOM

■ Clean and dry? |

|

Stored refuse or chemicals? |

■Describe items in need of attention

MAJOR MECHANICAL EQUIPMENT

■Preventive maintenance (PM) plan in use? Control System

■Type

■System operation

■Date of last calibration

Boilers

■ Rated Btu input |

|

Condition |

■Combustion air: is there at least one square inch free area per 2,000 Btu input?

■Fuel or combustion odors

Cooling Tower

■ Clean? no leaks or overflow? |

|

Slime or algae growth? |

■Eliminator performance

■Biocide treatment working? (list type of biocide)

■ Spill containment plan implemented? |

|

Dirt separator working? |

Chillers

■Refrigerant leaks?

■Evidence of condensation problems?

■Waste oil and refrigerant properly stored and disposed of?

191Indoor Air Quality Forms

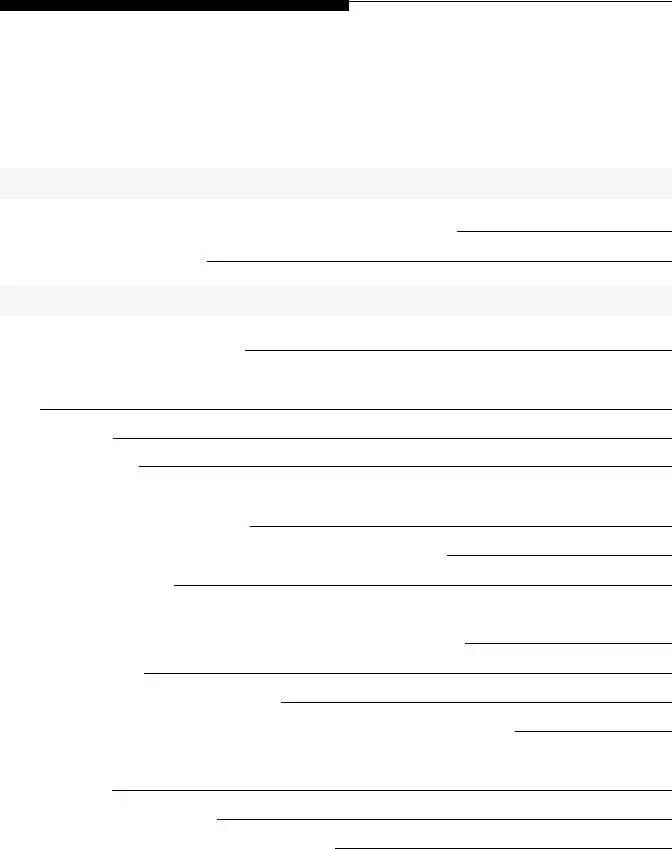

HVAC CHECKLIST - SHORT FORM

Page 2 of 4

Building Name: ____________________________________________ Address: __________________________________________

Completed by: ___________________________________________ Date: ______________ File Number: ___________________

AIR HANDLING UNIT

■ Unit identification |

|

Area served |

Outdoor Air Intake, Mixing Plenum, and Damper

■Outdoor air intake location

■Nearby contaminant sources? (describe)

■Bird screen in place and unobstructed?

■ Design total cfm |

|

outdoor air (O.A.) cfm |

|

date last tested and balanced |

|

|

|

|||

■ Minimum % O.A. (damper setting) |

|

Minimum cfm O.A. |

(total cfm x minimum % O.A.) |

|

= |

|

||||

|

|

|

|

|||||||

|

|

|

|

|

|

|

100 |

|

|

|

■Current O.A. damper setting (date, time, and HVAC operating mode)

■Damper control sequence (describe)

■Condition of dampers and controls (note date)

Fans

■ Control sequence

■ Condition (note date)

■ Indicated temperatures |

supply air |

|

mixed air |

|

return air |

|

outdoor air |

|

|

|||||||||||

■ Actual temperatures |

supply air |

mixed air |

return air |

|

outdoor air |

|

|

|||||||||||||

Coils |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

■ Heating fluid discharge temperature |

|

|

|

|

ΔT |

|

cooling fluid discharge temperature |

ΔT |

||||||||||||

■ Controls (describe) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

■ Condition (note date) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Humidifier |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

■ Type |

|

|

|

if biocide is used, note type |

|

|

|

|

|

|

|

|

||||||||

■Condition (no overflow, drains trapped, all nozzles working?)

■No slime, visible growth, or mineral deposits?

Indoor Air Quality Forms 192

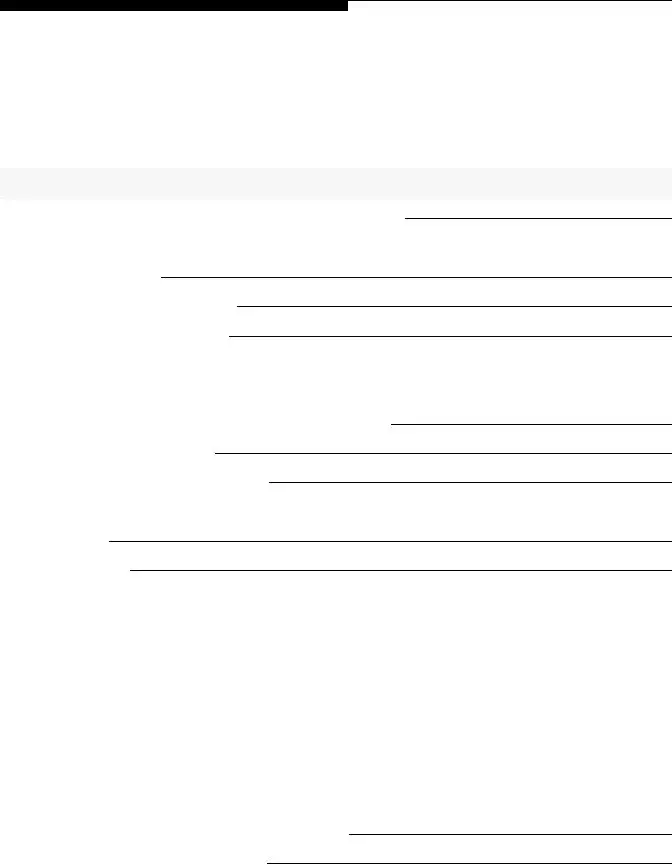

HVAC CHECKLIST - SHORT FORM

Page 3 of 4

Building Name: ____________________________________________ Address: __________________________________________

Completed by: ___________________________________________ Date: ______________ File Number: ___________________

DISTRIBUTION SYSTEM

Zone/ Room

System

Type

Supply Air |

Return Air |

|

Power Exhaust |

|

|||

|

|

|

|

|

|

|

|

ducted/ |

cfm* |

ducted/ |

cfm* |

cfm* |

|

control |

serves |

unducted |

|

unducted |

|

|

|

|

(e.g. toilet) |

|

|

|

|

|

|

|

|

Condition of distribution system and terminal equipment (note locations of problems)

■Adequate access for maintenance?

■Ducts and coils clean and obstructed?

■ Air paths unobstructed? |

supply |

|

return |

|

transfer |

|

exhaust |

|

|

|

|

|

|

■Note locations of blocked air paths, diffusers, or grilles

■Any unintentional openings into plenums?

■Controls operating properly?

■Air volume correct?

■Drain pans clean? Any visible growth or odors?

FILTERS

Location

Type/Rating

Size

Date Last Changed

Condition (give date)

193Indoor Air Quality Forms

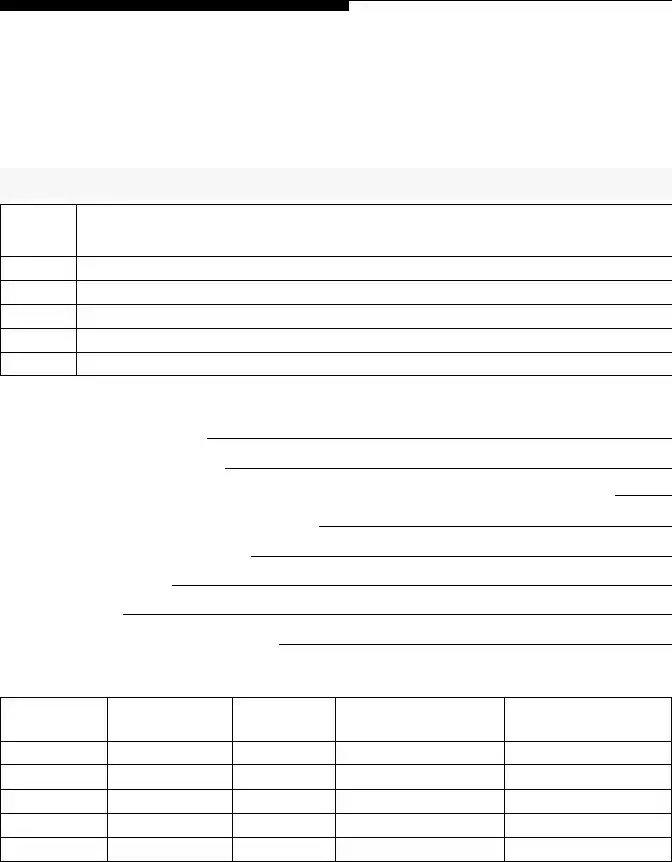

HVAC CHECKLIST - SHORT FORM

Page 4 of 4

Building Name: ____________________________________________ Address: __________________________________________

Completed by: ___________________________________________ Date: ______________ File Number: ___________________

OCCUPIED SPACE

Thermostat types

Zone/ Room

Thermostat Location

What Does Thermostat Control? (e.g., radiator, AHU- 3)

Setpoints

Summer |

Winter |

|

|

Measured Temperature

Day/ Time

Humidistats/Dehumidistats type

Zone/ Room

Humidistat/

Dehumidistat

Location

What Does It

Control?

Setpoints

(% RH)

Measured Temperature

Day/ Time

■Potential problems (note location)

■Thermal comfort or air circulation (drafts, obstructed airflow, stagnant air, overcrowding, poor thermostat location)

■Malfunctioning equipment

■Major sources of odors or contaminants (e.g., poor sanitation, incompatible uses of space)

Indoor Air Quality Forms 194

Form Data

| Fact Name | Detail |

|---|---|

| Form Purpose | Evaluates relationships between the HVAC system and indoor air quality. |

| Sections Discussed | Sections 2, 4, 6, and Appendix B focus on HVAC system's impact on indoor air quality. |

| Inspection Areas | Includes Mechanical Room, Major Mechanical Equipment, Air Handling Unit, Distribution System, Filters, and Occupied Space. |

| Mechanical Equipment Checks | Reviews preventive maintenance plans, control systems, boilers, cooling towers, chillers, and refrigerant management. |

| Air System Assessment | Examines unit identification, damper conditions, fan operation, coil conditions, and humidifier status. |

| Distribution System Evaluation | Assesses cleanliness, obstruction, control functionality, air volume, and drain pan condition. |

| Filter Maintenance | Records location, type, size, and last change date of filters, including their current condition. |

| Thermostat and Humidistat Checks | Details types, locations, control points, setpoints, and measured temperatures. |

| Overall Environment Inspection | Identifies potential problems, air circulation issues, malfunctioning equipment, and sources of odors or contaminants. |

| Governing Law(s) | Not specified; depends on state-specific regulations and standards for HVAC systems and indoor air quality. |

Instructions on Utilizing Hvac Inspection Checklist

Filling out an HVAC Inspection Checklist is a systematic way to ensure that heating, ventilation, and air conditioning (HVAC) systems are operating correctly and efficiently, and that they're contributing positively to the indoor air quality. This form requires detailed observations and data about different components and areas of the HVAC system. Below are steps to guide someone through the process of accurately completing this form. Remember to gather all necessary tools and information before starting, including access to the mechanical rooms and equipment, measurement tools for temperature and air flow, and any previous maintenance records.

- Start with the Building Name and Address at the top of the form to ensure the inspection is correctly attributed.

- Enter your name in the Completed by section to record who carried out the inspection.

- Fill in the Date of the inspection to maintain accurate records of when the evaluation took place.

- Provide the File Number if applicable; this could link to a specific maintenance or inspection cycle within record systems.

- Under the MECHANICAL ROOM section, check if the area is clean and dry. Note any stored refuse or chemicals and their conditions.

- In the MAJOR MECHANICAL EQUIPMENT section, indicate whether a preventive maintenance plan is in use. Detail the type and operation of the control system, and note the date of its last calibration.

- For each piece of equipment listed (Boilers, Cooling Tower, Chillers), check and note the conditions specified. This includes indications of leaks, odors, condition of eliminators, biocide treatment effectiveness, spill containment, and correct storage and disposal of hazardous materials.

- Proceed to the AIR HANDLING UNIT, check and record details such as unit identification, area served, outdoor air intake location, damper settings, and condition of dampers and controls.

- Note the design and actual air flow information, including temperatures of supply, mixed, return, and outdoor air.

- Assess and record the condition of coils, humidifiers, and their effectiveness, ensuring no visible growth or blockage is present.

- Under DISTRIBUTION SYSTEM, examine and describe the condition of the system and terminal equipment, noting any problems with access, cleanliness, and operation of the control systems.

- Inspect the condition of FILTERS, including their location, type, size, and the date they were last changed. Note any issues observed with their current condition.

- In the OCCUPIED SPACE section, report on thermostat types, locations, control specifics, setpoints for summer and winter, and the measured temperature. Complete similar steps for humidistats/dehumidistats.

- Finally, identify potential problems within the occupied space, regarding thermal comfort, air circulation, malfunctioning equipment, and sources of odors or contaminants. Be specific about the location of these issues.

Once the form is fully completed, review all sections to ensure completeness and accuracy before submitting. The information provided will enable targeted actions to maintain or improve the HVAC system's performance and indoor air quality.

Obtain Answers on Hvac Inspection Checklist

What is the purpose of an HVAC Inspection Checklist?

The purpose of an HVAC Inspection Checklist is to ensure the heating, ventilation, and air conditioning (HVAC) system in a building is clean, properly maintained, and functioning efficiently. It helps identify areas that need attention or repair, thereby improving indoor air quality and reducing energy costs. By following a structured assessment, such as checking for cleanliness in the mechanical room, the operational status of major mechanical equipment, and the condition of air handling units, a comprehensive evaluation of the system’s health is achieved.

Who should complete the HVAC Inspection Checklist?

The HVAC Inspection Checklist should be completed by a trained and qualified individual. This could be an experienced HVAC technician, a building maintenance professional, or a facility manager who has an understanding of HVAC systems and indoor air quality standards. Given the technical nature of the checklist, including assessments of combustion air requirements, preventive maintenance plans, and biocide treatments, it's crucial that the person conducting the inspection has the expertise to accurately evaluate and interpret the system's condition.

How often should the HVAC Inspection Checklist be used?

The frequency at which the HVAC Inspection Checklist should be used can vary based on several factors, including the age of the system, its usage intensity, and specific local regulations. However, as a general guideline, it is advisable to complete a thorough inspection at least once a year. More frequent checks might be necessary for older systems or in environments with higher levels of dust, chemicals, or other contaminants that could impact indoor air quality and system performance.

What are some key items included in the checklist?

Key items included in the checklist cover a broad range of components and considerations essential for HVAC system evaluation. These include:

- The condition and cleanliness of the mechanical room.

- Preventive maintenance plans for major mechanical equipment.

- Control system calibration and operation.

- Outdoor air intake and the presence of potential contaminant sources.

- Efficiency and condition of boilers, chillers, and cooling towers.

- Proper functionality of the air handling unit, including filters, dampers, and fans.

- Assessment of the distribution system for clean ducts and unobstructed air paths.

- Lastly, evaluation of occupied spaces for thermal comfort and control equipment functionality.

What happens if a problem is identified using the checklist?

If a problem is identified using the checklist, the next steps include assessing the severity of the issue, determining the best course of action for correction, and scheduling necessary repairs or adjustments. Minor issues might be resolved through immediate cleaning or adjustments during the inspection. More significant problems, however, may require professional service or parts replacement. Documenting these findings is crucial for maintaining a record of the system’s condition and to ensure all identified issues are addressed promptly.

Can the HVAC Inspection Checklist help improve energy efficiency?

Yes, the HVAC Inspection Checklist can significantly help improve energy efficiency. By identifying issues such as refrigerant leaks, improper damper settings, and other inefficiencies within the system, corrective actions can be taken to ensure the HVAC system runs more efficiently. Not only does this reduce energy consumption, but it also contributes to cost savings on utility bills and extends the life of the equipment by preventing overuse and premature failure.

Where can one find an HVAC Inspection Checklist?

An HVAC Inspection Checklist can typically be found through professional HVAC service providers, building maintenance organizations, or online resources that specialize in facility management and maintenance. Some manufacturers of HVAC equipment might also provide checklists tailored to their systems. Additionally, professional associations involved in heating, ventilation, and air conditioning may offer standardized checklists or guidelines for conducting thorough inspections and maintenance activities.

Common mistakes

When filling out the HVAC Inspection Checklist form, a few common errors can lead to incomplete or inaccurate reporting, potentially compromising the assessment of the HVAC system's health. These mistakes can affect everything from indoor air quality to system efficiency. Here are four mistakes often made:

- Not Checking All the Required Sections: The form is divided into different sections that cover everything from the mechanical room to the occupied space. Each section has its specific requirements for inspection. Failing to thoroughly check each section can lead to an incomplete assessment of the HVAC system. This includes overlooking Sections 2, 4, and 6, as well as Appendix B, which specifically discuss the relationship between the HVAC system and indoor air quality.

- Overlooking the Details in Descriptions: Many sections ask for descriptions, such as the condition of major mechanical equipment or the identification of nearby contaminant sources to outdoor air intakes. Glossing over these descriptions or providing vague responses can miss crucial details that could indicate system issues or need for maintenance.

- Inaccurate or Incomplete Recording of Measurements: Precise data, like the date of last calibration, design total cfm outdoor air, minimum percentage of outdoor air (O.A.) damper setting, or conditions and temperatures of air supply, are vital for evaluating system performance. Errors in recording this data or leaving it blank can mislead the analysis, resulting in ineffective recommendations.

- Skipping Over the Condition Assessment: The form requires noting the condition of various components at multiple points, from air handling units to filters and distribution systems. Not thoroughly assessing or omitting the condition, whether due to assuming it's unchanged or through oversight, can prevent the identification of issues needing resolution like leaks, blockages, or inefficiency.

Accurately filling out the HVAC Inspection Checklist is crucial for maintaining an effective and healthy indoor air environment. It requires attention to detail, a thorough understanding of the HVAC system components, and diligent recording of findings. Avoiding the above mistakes helps ensure a comprehensive assessment, leading to a healthier, safer, and more comfortable indoor space.

Documents used along the form

When managing HVAC systems, whether for routine inspections or during specific maintenance tasks, the HVAC Inspection Checklist is an essential tool. However, this checklist is just a part of a broader documentation suite necessary for comprehensive HVAC management and air quality assessment. For professionals in this field, several other forms and documents often complement the HVAC Inspection Checklist to ensure all aspects of HVAC operation and its impact on indoor air quality are monitored closely.

- Preventive Maintenance Schedule: This document outlines the planned maintenance activities for the HVAC system components over a specific period. It helps in planning and ensuring that all parts are serviced regularly to prevent sudden failures.

- Repair and Maintenance Log: A record of all the repairs, replacements, and maintenance activities performed on the HVAC system. It includes dates, details of the service, and names of technicians involved. This log is crucial for tracking the system's history and identifying recurring issues.

- Equipment Manuals and Specifications: Manufacturers provide these documents, containing detailed instructions on installation, operation, and maintenance of HVAC units. These manuals are indispensable for troubleshooting and ensuring compliance with specific technical standards.

- Indoor Air Quality (IAQ) Assessment Form: Used alongside the HVAC checklist to evaluate air quality issues within a building, this form helps in identifying sources of contaminants and areas requiring improvement.

- Energy Efficiency Audit Records: These documents contain the findings from evaluations aimed at measuring the HVAC system's energy consumption. Recommendations for enhancing energy efficiency and reducing operation costs are also included.

- Compliance Certificates: Necessary for proving adherence to local, state, and federal regulations concerning HVAC systems and indoor air quality. These certificates may need to be presented during inspections or when seeking insurance claims.

- Customer Feedback Forms: While not technical, collecting feedback from the occupants of a building on their comfort levels can provide insights into the HVAC system's performance and areas that may need adjustments.

In conclusion, while the HVAC Inspection Checklist is fundamental for assessing the operational health of HVAC systems, it forms just a part of a broad array of documents required for holistic HVAC management. Each document plays a role in ensuring the system's efficiency, compliance with standards, and the overall well-being of building occupants. Understanding and maintaining these documents facilitate a proactive approach to HVAC maintenance, ultimately contributing to sustained indoor air quality and comfort.

Similar forms

The Building Inspection Checklist is similar to the HVAC Inspection Checklist in that it is utilized by inspectors or maintenance teams to evaluate the condition and safety of a building's structural elements. This encompasses checking for signs of damage in walls, floors, and ceilings, ensuring the electrical systems are up to code, and examining plumbing fixtures for leaks or other issues, much like the HVAC Checklist inspects various components of heating, ventilation, and air conditioning systems for proper operation and maintenance needs.

A Fire Safety Inspection Form bears resemblance to the HVAC Inspection Checklist through its structured approach to assessing critical safety features within a building. It involves checking fire extinguishers, alarms, and sprinkler systems to confirm they are functioning correctly and accessible in case of emergency. Both forms prioritize the safety and well-being of occupants by ensuring that the systems intended to protect them are in good working order.

The Equipment Maintenance Log shares similarities with the HVAC Inspection Checklist by documenting and tracking the condition and service history of specific pieces of equipment. This log typically includes information about the date of the last service, the type of maintenance performed, and any repairs needed or completed, analogous to how the HVAC checklist records the maintenance status of major mechanical equipment, calibration dates for control systems, and conditions of air handling units.

Energy Audit Forms are akin to the HVAC Inspection Checklist in their role of identifying opportunities for energy conservation within a building. These forms analyze how energy is used and identify inefficiencies, such as poor insulation or outdated HVAC systems that consume excessive power. While the energy audit focuses broadly on all aspects of a building's energy use, the HVAC checklist specifically examines the performance and efficiency of heating, ventilation, and air conditioning systems as they relate to energy consumption.

Dos and Don'ts

When filling out the HVAC Inspection Checklist form, attention to detail and adherence to guidelines can significantly impact the accuracy and effectiveness of the inspection. Below are essential dos and don'ts to keep in mind:

- Do make sure the building name and address are filled out accurately to ensure the inspection is associated with the correct location.

- Do complete all sections thoroughly, especially those relating to indoor air quality such as Sections 2, 4, and 6, and Appendix B, to highlight any potential concerns or issues.

- Do include the date of inspection and file number clearly at the top of the form to keep records organized and easily accessible for future reference.

- Do provide detailed descriptions of items that need attention, ensuring that actionable information is conveyed for maintenance or repair teams.

- Do verify all mechanical equipment and system operations against the checklist criteria, noting the date of last calibration, maintenance plans in use, and any signs of wear or malfunction.

- Don't overlook any sections labeled as not applicable without confirming they truly are irrelevant to the building in question. Sometimes what seems unnecessary at first glance could be important upon a closer look.

- Don't rush through the checklist. Take the necessary time to inspect each element carefully. A hurried inspection can lead to oversight of critical issues that might affect the building's indoor air quality and occupants' safety.

By adhering to these guidelines, individuals filling out the HVAC Inspection Checklist can contribute significantly to maintaining a safe and comfortable environment for building occupants.

Misconceptions

When it comes to maintaining and inspecting HVAC (Heating, Ventilation, and Air Conditioning) systems, there are several misconceptions that can lead to inefficiencies, unhealthy indoor air quality, or unnecessary costs. A closer look at the HVAC Inspection Checklist form reveals common misunderstandings that can have significant impacts:

- It’s only for experts. Many assume that the form is too technical for anyone but professionals. While it's detailed, it’s also designed to guide building managers through a comprehensive check, helping identify potential issues before they require expensive repairs.

- Indoor air quality is barely affected by HVAC. Sections 2, 4, and 6, alongside Appendix B, explicitly discuss the impact of HVAC systems on indoor air quality, underscoring its importance. These components ensure that the system not only controls temperature but also contributes to a healthier indoor environment.

- Preventive Maintenance is optional. The checklist emphasizes the need for a preventive maintenance (PM) plan with sections such as Major Mechanical Equipment checks, showcasing its critical role in preventing breakdowns and ensuring efficiency.

- Minor signs of wear or slight damage can be ignored. Each item, even noting whether areas are clean and dry or if there are stored chemicals, points towards potential risk areas. Even minor issues can signal the start of larger problems, making it crucial to address them promptly.

- Calibration is a one-time task. The control system's last calibration date is a checklist item, indicating the necessity of regular calibrations to ensure system accuracy and efficiency.

- The checklist is only concerned with the HVAC equipment itself. Actually, it covers a broad range of elements including outdoor air intake and distribution system conditions, emphasizing the system's context within the building environment and its comprehensive impact on air quality and comfort.

- Only specific areas of the HVAC system need regular inspection. From cooling towers to filters and even the occupied space’s thermostats, the comprehensive nature of the checklist illustrates the interconnectedness of the system's parts. Each component, no matter how small it seems, plays a vital role in the overall functioning of the HVAC system.

Understanding these misconceptions and the true nature of the HVAC Inspection Checklist can lead to better maintenance practices, resulting in more efficient operations, improved air quality, and potentially significant cost savings over time. By paying attention to each aspect of this checklist, building managers can ensure their HVAC systems are in top condition, providing a safe and comfortable environment for occupants.

Key takeaways

Filling out and using the HVAC Inspection Checklist form is an essential process for ensuring the efficient operation and maintenance of heating, ventilation, and air conditioning (HVAC) systems within a building. It serves not only as a tool for evaluating the current condition of the HVAC system but also as a guide to identify potential issues that could affect indoor air quality and overall system performance. Below are four key takeaways that should be considered when dealing with this crucial document:

- Comprehensive inspection areas: The checklist is divided into sections that cover every critical aspect of HVAC system inspection, including the mechanical room, major mechanical equipment, air handling units, distribution system, and the conditions within occupied spaces. This thorough approach ensures that no component of the HVAC system is overlooked, from preventive maintenance plans and system calibration to air quality within occupied spaces.

- Focus on indoor air quality: Sections 2, 4, and 6, along with Appendix B, specifically address the relationship between HVAC systems and indoor air quality. This highlights the checklist’s role not only in maintaining system efficiency and reliability but also in ensuring a healthy indoor environment. Items such as air intake locations, outdoor air percentages, and conditions of filters are scrutinized to safeguard against contaminants and ensure proper ventilation.

- Maintenance and problem identification: The checklist prompts the identification of items needing attention, such as leaks, odors, or malfunctioning equipment, and assesses the performance of preventive maintenance plans. It’s designed to catch early signs of potential issues, facilitating prompt corrective actions that can prevent costly repairs and extended downtimes in the future.

- Record-keeping for compliance and efficiency: Completing the HVAC Inspection Checklist creates a documented record of the system’s condition at the time of inspection. This documentation is invaluable for compliance with health and safety regulations, warranty requirements, and can serve as a basis for discussions with repair services, insurance companies, and during audits. The included details like the building name, address, and date of inspection ensure that the record is easily referenced and organized for future use.

By adhering to the structured approach laid out in the HVAC Inspection Checklist, building operators and maintenance teams can significantly enhance the operational efficiency of HVAC systems, extend their lifetime, and improve the indoor air quality for occupants. It’s an indispensable tool in the proactive management and maintenance of building HVAC infrastructures.

Popular PDF Forms

Form It38 - Declare the completeness and accuracy of the form in the declaration section, providing signatures and date.

Va Lay Statement Form - Its completion allows the VA to reach out to designated healthcare providers for relevant medical records.