Blank Job Briefing PDF Template

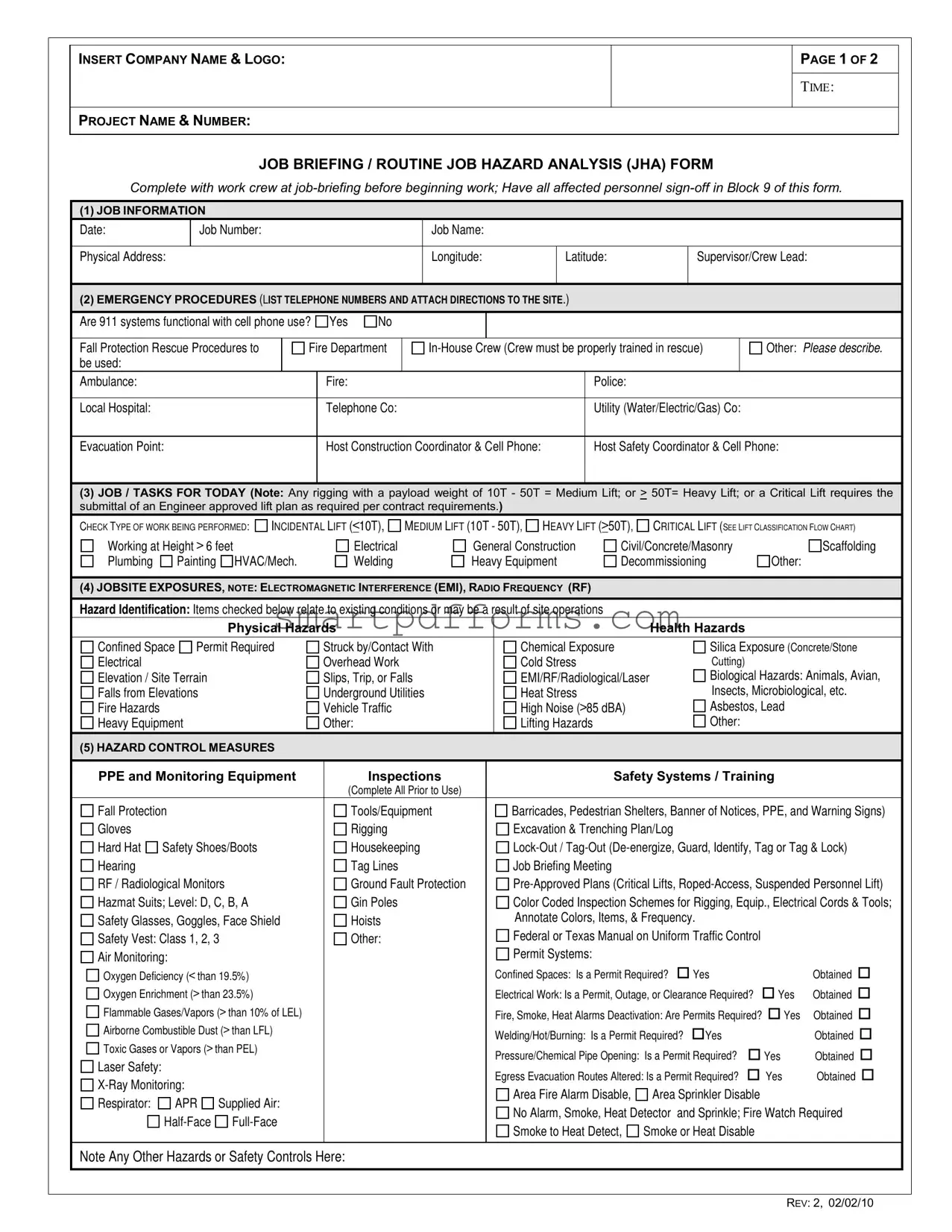

Ensuring the safety and preparedness of a work crew before the commencement of any project is not just a matter of compliance, but a critical component of operational excellence. The Job Briefing / Routine Job Hazard Analysis (JHA) form serves as a foundational tool in achieving this goal. This comprehensive document, meticulously designed for teams to fill out, starts with capturing essential job information, including project specifics, job number, and supervisor details. It moves on to detail emergency procedures, clearly listing out contact numbers and directions crucial in emergencies, and verifying the functionality of 911 systems with cell phones. The form then guides the crew through identifying the tasks for the day and classifying their nature and potential hazards - from working at heights to dealing with electrical installations. It doesn't stop there; the JHA form assesses jobsite exposures, categorizing them under physical and health hazards, thereby ensuring that each risk factor is acknowledged and prepared for. Safety measures get a spotlight, with emphasis on Personal Protective Equipment (PPE), safety systems, and equipment inspections. This form even delves into specialized areas such as fall protection, civil work, and handling of suspended personnel platforms, making sure every scenario is accounted for. Finally, it culminates in a section dedicated to reviews and signatures, underscoring the collaborative effort required for a safe and efficient work environment. Through its varied sections, the Job Briefing / Routine Job Hazard Analysis (JHA) form epitomizes a proactive approach to workplace safety, reflecting a commitment to protecting the workforce while promoting a culture of accountability and thoroughness in hazard assessment.

Preview - Job Briefing Form

INSERT COMPANY NAME & LOGO:

PROJECT NAME & NUMBER:

PAGE 1 OF 2

TIME:

JOB BRIEFING / ROUTINE JOB HAZARD ANALYSIS (JHA) FORM

Complete with work crew at

(1) JOB INFORMATION

Date: |

Job Number: |

Job Name: |

|

|

|

Physical Address: |

|

Longitude: |

|

|

|

Latitude:

Supervisor/Crew Lead:

(2)EMERGENCY PROCEDURES (LIST TELEPHONE NUMBERS AND ATTACH DIRECTIONS TO THE SITE.)

Are 911 systems functional with cell phone use? |

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fall Protection Rescue Procedures to |

Fire Department |

|

Other: PLEASE DESCRIBE. |

||||

be used: |

|

|

|

|

|

|

|

Ambulance: |

|

Fire: |

|

|

Police: |

|

|

|

|

|

|

|

|

||

Local Hospital: |

|

Telephone Co: |

|

Utility (Water/Electric/Gas) Co: |

|

||

Evacuation Point:

Host Construction Coordinator & Cell Phone:

Host Safety Coordinator & Cell Phone:

(3)JOB / TASKS FOR TODAY (Note: Any rigging with a payload weight of 10T - 50T = Medium Lift; or > 50T= Heavy Lift; or a Critical Lift requires the submittal of an Engineer approved lift plan as required per contract requirements.)

CHECK TYPE OF WORK BEING PERFORMED:

INCIDENTAL LIFT (<10T),

MEDIUM LIFT (10T - 50T),

HEAVY LIFT (>50T),

CRITICAL LIFT (SEE LIFT CLASSIFICATION FLOW CHART)

Working at Height > 6 feet

Plumbing

Painting

Painting

HVAC/Mech.

HVAC/Mech.

Electrical Welding

General Construction Heavy Equipment

Civil/Concrete/Masonry Decommissioning

Scaffolding

Other:

(4) JOBSITE EXPOSURES, NOTE: ELECTROMAGNETIC INTERFERENCE (EMI), RADIO FREQUENCY (RF)

HAZARD IDENTIFICATION: Items checked below relate to existing conditions or may be a result of site operations

|

|

Physical Hazards |

|

Health Hazards |

||

|

|

|

|

|

|

|

|

Confined Space |

Permit Required |

Struck by/Contact With |

Chemical Exposure |

Silica Exposure (Concrete/Stone |

|

|

Electrical |

|

Overhead Work |

Cold Stress |

Cutting) |

|

|

Elevation / Site Terrain |

Slips, Trip, or Falls |

EMI/RF/Radiological/Laser |

Biological Hazards: Animals, Avian, |

||

|

Falls from Elevations |

Underground Utilities |

Heat Stress |

Insects, Microbiological, etc. |

||

|

Fire Hazards |

|

Vehicle Traffic |

High Noise (>85 dBA) |

Asbestos, Lead |

|

|

Heavy Equipment |

|

Other: |

Lifting Hazards |

Other: |

|

|

|

|

|

|

|

|

|

(5) HAZARD CONTROL MEASURES |

|

|

|

|

|

|

|

|

|

|

|

|

PPE and Monitoring Equipment |

Inspections |

Safety Systems / Training |

|

|

||||

|

|

|

(Complete All Prior to Use) |

|

|

|

|

|

Fall Protection |

|

Tools/Equipment |

Barricades, Pedestrian Shelters, Banner of Notices, PPE, and Warning Signs) |

|||||

Gloves |

|

|

Rigging |

Excavation & Trenching Plan/Log |

|

|

|

|

Hard Hat |

Safety Shoes/Boots |

Housekeeping |

|

|||||

Hearing |

|

|

Tag Lines |

Job Briefing Meeting |

|

|

|

|

RF / Radiological Monitors |

Ground Fault Protection |

|||||||

Hazmat Suits; Level: D, C, B, A |

Gin Poles |

Color Coded Inspection Schemes for Rigging, Equip., Electrical Cords & Tools; |

||||||

Safety Glasses, Goggles, Face Shield |

Hoists |

Annotate Colors, Items, & Frequency. |

|

|

|

|||

|

|

|

|

|

||||

Safety Vest: Class 1, 2, 3 |

Other: |

Federal or Texas Manual on Uniform Traffic Control |

|

|

||||

|

|

|

|

|

||||

Air Monitoring: |

|

|

Permit Systems: |

|

|

|

|

|

|

|

|

|

|

|

|

||

Oxygen Deficiency (< than 19.5%) |

|

Confined Spaces: Is a Permit Required? Yes |

|

Obtained |

|

|||

Oxygen Enrichment (> than 23.5%) |

|

Electrical Work: Is a Permit, Outage, or Clearance Required? Yes |

Obtained |

|

||||

Flammable Gases/Vapors (> than 10% of LEL) |

|

Fire, Smoke, Heat Alarms Deactivation: Are Permits Required? Yes |

Obtained |

|||||

Airborne Combustible Dust (> than LFL) |

|

Welding/Hot/Burning: Is a Permit Required? Yes |

|

Obtained |

||||

|

|

|

|

|

||||

Toxic Gases or Vapors (> than PEL) |

|

Pressure/Chemical Pipe Opening: Is a Permit Required? |

Yes |

Obtained |

|

|||

Laser Safety: |

|

|

|

|||||

|

|

|

Egress Evacuation Routes Altered: Is a Permit Required? |

Yes |

Obtained |

|||

|

|

|||||||

|

|

Area Fire Alarm Disable, |

Area Sprinkler Disable |

|

|

|||

Respirator: |

APR |

Supplied Air: |

|

|

|

|||

|

No Alarm, Smoke, Heat Detector and Sprinkle; Fire Watch Required |

|

||||||

|

|

|

||||||

|

|

Smoke to Heat Detect, |

Smoke or Heat Disable |

|

|

|||

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

Note Any Other Hazards or Safety Controls Here:

REV: 2, 02/02/10

INSERT COMPANY NAME & LOGO:

PROJECT NAME & NUMBER:

PAGE 2 OF 2

TIME:

JOB BRIEFING / ROUTINE JOB HAZARD ANALYSIS (JHA) FORM

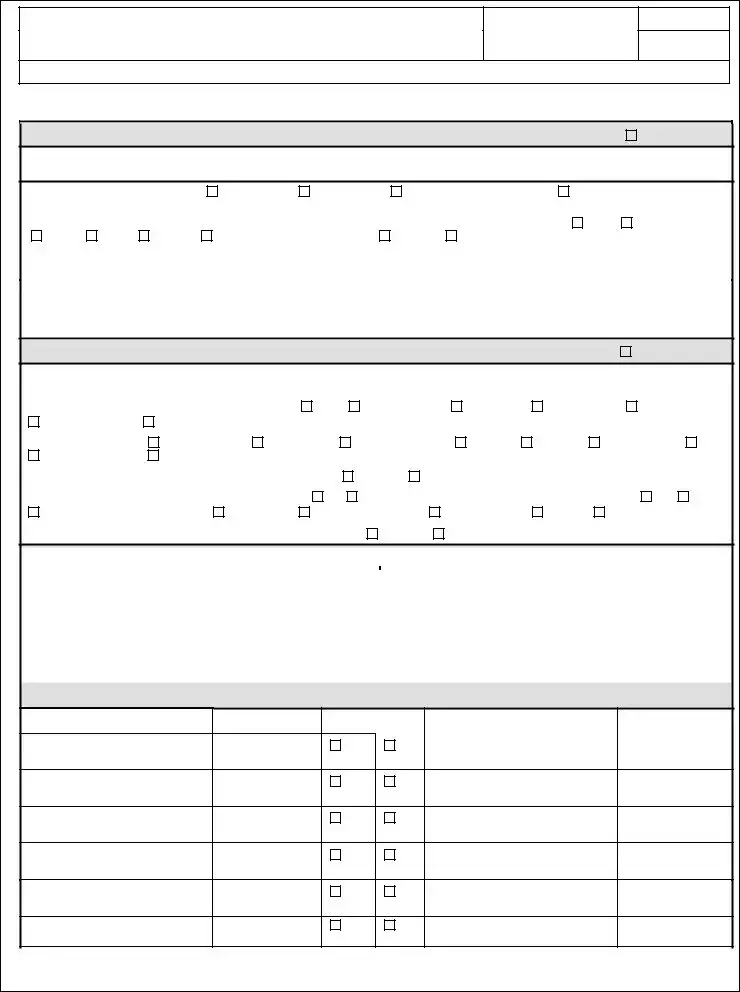

(6)COMPLETE FOR CIVIL WORK (PLEASE NOTE: ENGINEER APPROVED TRENCHING PLAN REQUIRED FOR TRENCHES > 5’)

NOT APPLICABLE

NOTE: Notify and confirm proper procedures, mitigation and/or protective steps taken with your company’s designated Safety Representative & Site Manager before

entering: any trench or any general excavation that is greater than 5’ deep; or any Confined Space.

1. Describe type and depth of excavations

Type A Soil/Rock

Type B Soil/Rock

Type C Soil/Rock:

2.

Shoring |

Trench |

Shield/Box |

Ladder in Trench > 5 Feet & Every 25’ Sump Pump LOTO: |

3.Describe elevation/site terrain/environmental concerns or hazards:

4.Describe hazards with site/vehicle access (High Traffic, Heavy Haul, Boom Cranes, and Storage of Materials/HazMat:

5.Describe the type of electrical or gas concerns or hazards (e.g. Electrical/Gas/Fiber Optic Lines):

Sloping

Benching

(7) FALL PROTECTION & USING SUSPENDED PERSONNEL PLATFORM (Complete for Working at Heights and

NOT APPLICABLE

Type of Elevated Work & Height: |

|

|

Type of Tower or Building: |

|

|

|

||

Describe the fall protection system to be used when working aloft. |

Lifeline |

Personal Fall Arrest |

Safety Monitor |

Qualified Climber |

Safety Net |

|||

Ladder Safety Device |

Roped Access (Requires Roped Access JHA): |

|

|

|

|

|

||

Fall protection to be used. |

Full Body Harness |

One Lanyard |

Two Lanyards (100%) |

Rope Grab |

Cable Grab |

Retractable Lifeline |

||

Ascenders/Descenders |

Anchorage Points, Belay, & Straps: |

|

|

|

|

|

|

|

Ropes

Has each employee inspected his or her fall protection equipment? |

|

Yes |

No |

|

|

|

|

Hoisting Equipment to be used: < 20’ Encroachment of Power Lines, |

Yes |

No; If yes, ID Voltage _______KV; |

Yes |

||||

Suspended Personnel Platform/basket |

Forklift Platform |

Crane/Boom/Aerial Truck |

Scissor/Snorkel Lift |

Gin Pole |

Roped Access |

||

Suspended Personnel Platform Checklist and/or Critical Lift Plan Completed? |

Yes |

No |

|

|

|

||

|

|

|

|

|

|

|

|

No

|

(8) REVIEWS AND SIGNATURES |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

GC Superintendent /Foreman |

|

|

|

|

|

|

|

|

|

|

|

|

|

Name |

Signature/Date |

|

Name |

Signature/Date |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(9)PROJECT PERSONNEL ACKNOWLEDGEMENT (ALL AFFECTED PERSONNEL SIGN AFTER JOB BRIEFING)

Name:

Company: |

CPR / First Aid |

Name: |

Company: |

|

|

Yes |

|

Yes |

|

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

REV: 2, 02/02/10

Form Data

| Fact Name | Detail |

|---|---|

| Form Purpose | The Job Briefing / Routine Job Hazard Analysis (JHA) Form is designed to be filled out with the work crew before starting work to identify and mitigate job hazards. |

| Form Structure | It is a two-page form that includes sections on job information, emergency procedures, daily tasks, jobsite exposures, hazard control measures, specific considerations for civil work, fall protection, and acknowledgements. |

| Emergency Procedures | Includes comprehensive contact information and procedures for emergencies, asking about the functionality of 911 systems with cell phones and listing emergency contacts. |

| Task Specific Details | Details specific types of work being performed and associated risk levels, including lift classifications and working at heights. |

| Jobsite Exposures | Identifies potential physical and health hazards on the site, such as electromagnetic interference, chemical exposures, and fire hazards. |

| Hazard Control Measures | Outlines required personal protective equipment (PPE), safety systems and training, and other controls to mitigate identified hazards. |

| State-specific Laws | References to federal or Texas laws, such as the Manual on Uniform Traffic Control for Texas, indicating this form can be customized to include state-specific laws and guidelines. |

| Sign-off Requirement | Mandates sign-off by all affected personnel in the Project Personnel Acknowledgement section to ensure acknowledgment of hazards and control measures before work starts. |

Instructions on Utilizing Job Briefing

Filling out the Job Briefing and Routine Job Hazard Analysis (JHA) Form is a crucial step before beginning any project work. This process ensures that all work crew members are aware of the job details, potential hazards, and emergency procedures. It also serves as a record that all affected personnel have acknowledged the risks and safety protocols. Here’s how to properly fill out the form:

- Start by inserting your company’s name and logo at the top of the form, along with the project name and number. Note that the form is "Page 1 of 2."

- Record the time of the job briefing to ensure all information is timely and accurate.

- Under (1) JOB INFORMATION, fill out the date, job number, job name, physical address, longitude, latitude, and the supervisor/crew lead’s information.

- In (2) EMERGENCY PROCEDURES, list all relevant telephone numbers for emergency services and directions to the site. Specify whether 911 is functional via cell phone and detail fall protection and rescue procedures.

- Check the boxes in (3) JOB / TASKS FOR TODAY that apply to the type of work being performed. If your task involves lifting, make sure to note the weight and whether an engineer-approved lift plan is required.

- Identify any job site exposures in (4) JOBSITE EXPOSURES by checking the appropriate boxes for physical and health hazards.

- Detail the hazard control measures in (5) HAZARD CONTROL MEASURES. This includes PPE, equipment inspections, safety systems, and training to be undertaken.

- If applicable, complete details for civil work in (6) COMPLETE FOR CIVIL WORK by describing the type of excavation, control measures, and any potential hazards relating to the site and work environment.

- For tasks involving heights, fill out (7) FALL PROTECTION & USING SUSPENDED PERSONNEL PLATFORM section with details about the fall protection system and equipment to be used.

- Have the GC Superintendent/Foreman and lower-tier subcontractor supervisor sign off in the (8) REVIEWS AND SIGNATURES section.

- In the (9) PROJECT PERSONNEL ACKNOWLEDGEMENT section, have all affected personnel sign off after the job briefing. This confirms that everyone is aware of and agrees to the job details and safety measures.

Once the form is completed and signed by all relevant parties, it serves as a formal record of the job briefing and hazard analysis. This document should be retained for the duration of the project, ensuring compliance with safety regulations and facilitating effective communication among the work crew.

Obtain Answers on Job Briefing

What is a Job Briefing / Routine Job Hazard Analysis (JHA) Form?

A Job Briefing / Routine Job Hazard Analysis (JHA) Form is a document designed to be filled out with a work crew before beginning a job. Its purpose is to analyze potential hazards related to the job, decide emergency procedures, and outline the tasks for the day. It includes details on job information, emergency procedures, job tasks, jobsite exposures, hazard control measures, specific instructions for civil work and fall protections, and requires the signatures of all affected personnel as an acknowledgment of the briefing.

Who should fill out the Job Briefing / Routine Job Hazard Analysis (JHA) Form?

This form should be completed with the entire work crew at the job briefing before the start of work. It involves input from the supervisor or crew lead and all affected personnel, who must sign off in the designated section of the form to acknowledge their participation and understanding of the job’s safety requirements.

Why is it important to fill out the Job Briefing / Routine Job Hazard Analysis (JHA) Form?

Filling out the form is crucial for ensuring that all team members are aware of the job's potential hazards, emergency procedures, and safety measures. This preparation helps in minimizing risks, ensuring a safer work environment, and is often a requirement for compliance with safety regulations and policies.

What should be included in the emergency procedures section?

In the emergency procedures section, you should list important telephone numbers, directions to the site, information on whether 911 systems work with cell phones, fall protection rescue procedures, and contacts for the ambulance, fire, police, local hospital, telephone, utility companies, evacuation points, and host construction and safety coordinators.

How do you determine the type of work being performed from the options provided?

You should check the type of work being performed based on the tasks scheduled for the day. Options include but are not limited to incidental, medium, or heavy lifts based on weight, working at height, plumbing, electrical work, welding, general construction, and more. Any special conditions such as working with hazardous materials or in confined spaces should also be noted.

What are hazard control measures, and how are they determined?

Hazard control measures are strategies and tools designed to minimize the risks associated with identified hazards at the jobsite. These measures can include personal protective equipment (PPE), safety system training, barricades, and specific procedures like lock-out / tag-out for electrical systems. They are determined by assessing the potential hazards identified in the job hazard analysis and selecting the appropriate controls based on industry standards and company policies.

What happens after completing the Job Briefing / Routine Job Hazard Analysis (JHA) Form?

After completing the form, it must be signed by the general contractor (GC) superintendent or foreman, lower-tier subcontractor supervisor, and all affected personnel as an acknowledgment of the briefing and understanding of the job's risks and safety measures. This ensures accountability and compliance with safety protocols. The completed form serves as a record that the briefing occurred and is important for audits, investigations, or compliance checks.

Common mistakes

Filling out a Job Briefing/Routine Job Hazard Analysis (JHA) Form is a critical component of project management and worker safety. However, during this process, people often make errors that can impact the effectiveness of the briefing or the accuracy of the hazard assessment. Here are eight common mistakes:

Not Inserting Company Name and Logo: Often, individuals overlook the need to insert the company name and logo at the beginning of the document. This step is essential for the form's identification and ensures it's traceable back to the company and specific project.

Incomplete Job Information: Skipping details under the job information section such as job number, name, physical address, and supervisor or crew lead’s names impacts the clarity and specificity of the briefing form, potentially leading to confusion about the job’s specifics.

Skipping Emergency Procedures: Failure to list emergency telephone numbers or attach directions to the site can be crucial oversights. Immediate access to this information is vital in case of an emergency.

Leaving the Job/Tasks for Today Section Unchecked: Not specifying the types of work being performed, such as whether the job involves lifting, working at heights, or handling hazardous materials, can lead to insufficient preparation and risk assessment.

Misidentifying Jobsite Exposures: Incorrectly identifying or overlooking potential jobsite exposures, like electromagnetic interference or chemical exposure, can fail to alert workers to significant risks.

Inadequate Hazard Control Measures Documentation: Not completing the hazard control measures section thoroughly, including personal protective equipment (PPE) and safety systems or training, compromises worker safety and compliance with safety regulations.

Overlooking Permit Requirements: Neglecting to check or accurately fulfill permit requirements for confined spaces, electrical work, or hot work permits leaves the project and its workers vulnerable to unmitigated risks and potential legal repercussions.

Errors in Reviews and Signatures: Failing to obtain the necessary reviews and signatures from GC Superintendent/Foreman and Lower-tier Subcontractor Supervisor undermines the form's validity and misses an important checkpoint for review and acknowledgment of the hazards and safety measures.

Ensuring that each section of the Job Briefing/Routine Job Hazard Analysis (JHA) Form is meticulously completed is paramount for the safety and efficiency of the project. Identifying and avoiding these common mistakes can significantly enhance the effectiveness of the job briefing and hazard analysis process.

Documents used along the form

When managing a project, ensuring that every team member is on the same page is vital for ensuring safety and efficiency. The Job Briefing/Routine Job Hazard Analysis (JHA) form plays a crucial role in this process, but it often works best when accompanied by other forms and documents that collectively create a comprehensive overview of job expectations, safety requirements, and procedural compliance. These additional documents ensure that every base is covered, from initial planning to emergency procedures.

- Emergency Action Plan (EAP): This document outlines the procedures employees should follow in case of an emergency. It includes evacuation routes, assembly points, and roles and responsibilities during an emergency.

- Safety Data Sheets (SDS): These provide detailed information about chemicals and substances used on the job site, including their hazards and how to handle them safely. They are essential for ensuring chemical safety in the workplace.

- Incident Report Forms: Used to document any accidents, injuries, or near misses that occur on the job site. These forms are crucial for tracking incidents and developing strategies to prevent future occurrences.

- Equipment Inspection Checklists: Regular inspection and maintenance of equipment are vital for safe operations. These checklists ensure that all equipment is in good working order and safe to use.

- Permit to Work: This document is required for high-risk activities, such as working at heights or entering confined spaces. It ensures that all safety procedures have been followed before the work begins.

- Training Records: Keeping track of who has received training on specific tasks or equipment helps ensure that only qualified personnel perform certain jobs. It also helps in identifying training needs.

Taking the time to properly utilize and manage these documents in conjunction with the Job Briefing form can significantly enhance safety and operational efficiency on any project. They provide a structured approach to job planning and execution, ensuring that all team members are aware of their roles, responsibilities, and the risks associated with their tasks. Together, they form a crucial part of any project's safety and management protocols.

Similar forms

The Job Briefing form is a crucial element in ensuring the safety and organization of any project, especially in industries like construction, where hazards are prevalent. There are various documents similar in purpose and structure to the Job Briefing form, each designed to address specific aspects of project management, safety, and compliance. Understanding these documents can enhance project planning, execution, and safety protocols.

- Incident Report Forms: These forms are integral to documenting any accidents or safety incidents that occur on-site. Like the Job Briefing form, they help in identifying potential hazards but focus on capturing details post-incident to prevent future occurrences.

- Safety Meeting Minutes: These records are akin to the Job Briefing form in that they are used to document discussions about safety and operational concerns. However, they focus more on the discussions and outcomes of regular safety meetings rather than on the specifics of each job.

- Risk Assessment Forms: Like the Job Briefing form, these documents are used before the commencement of a task to identify potential hazards. The main difference is that Risk Assessment forms typically evaluate the likelihood and impact of risks in a more detailed and formal manner.

- Method Statements: Method statements provide detailed instructions on how to safely carry out a specific job or task, similar to the section of the Job Briefing form where tasks and hazard controls are listed. They are more detailed and are often used for complex or high-risk activities.

- Emergency Action Plans (EAP): While the Job Briefing form includes emergency procedures and contacts, an EAP is a comprehensive document that outlines procedures for all potential emergencies. It focuses on the broader scope of emergency preparedness rather than the specifics for a single job.

- Permit to Work: This document is required for high-risk work that could affect the safety of the workplace. Similar to the Job Briefing form, a Permit to Work ensures hazards are identified, and control measures are in place before work begins, but it also includes formal authorizations.

- Checklists for Equipment Inspections: These checklists ensure that equipment is safe to use before starting a job, akin to how the Job Briefing form includes checks for tools and equipment. However, inspection checklists are more specific, focusing solely on equipment safety.

Each of these documents plays a critical role in maintaining a safe work environment, and while they share similarities with the Job Briefing form, they each have a unique purpose in the broader context of project safety and management.

Dos and Don'ts

When completing the Job Briefing/Routine Job Hazard Analysis (JHA) Form, it is crucial to follow these guidelines to ensure the safety and efficiency of the project.

Do:Ensure that the company name and logo, along with the project name and number, are clearly filled out at the top of the form to properly identify the project.

Complete the form with the work crew during the job briefing before beginning any work to ensure everyone is aware of their roles and the hazards present.

Accurately fill out the job information section, including the date, job number, job name, physical address, and the supervisor/crew lead details to keep records straight.

List emergency procedures, including telephone numbers and directions to the site, to ensure quick response in case of an incident.

Forget to have all affected personnel sign off in Block 9 of the form after the job briefing. This acknowledgment is crucial for accountability and safety.

Ignore the details regarding the type of work being performed. Whether it's an incidental lift or working at height, correctly checking the type of work guides the necessary safety measures.

Omit details about jobsite exposures. Identifying physical and health hazards is key to implementing the correct hazard control measures.

Skip the hazard control measures section. Completing this section with appropriate safety systems and training ensures the crew's preparedness and safety compliance.

Misconceptions

When it comes to Job Briefing forms and Routine Job Hazard Analysis (JHA) documents, there are several common misconceptions that can lead to confusion or misuse. Let’s clear up some of these misunderstandings:

- Only the supervisor needs to understand the contents. A common misconception is that only the team leader or supervisor needs to fully understand the Job Briefing form. However, it's crucial that all crew members comprehend every part of the briefing. This is because the safety measures and hazard recognitions directly affect everyone on the site. Effective communication ensures that each team member is aware of potential risks and the steps they need to take to mitigate them.

- It’s just a formality. Some might think that completing the Job Briefing / Routine Job Hazard Analysis form is just ticking a box for compliance purposes. On the contrary, this document plays a key role in proactively identifying and mitigating job site hazards. Its completion is not just about compliance but about ensuring a safe working environment for all personnel involved.

- A one-time completion is enough. Thinking that this form needs to be filled out only once is a misconception. Job conditions, tasks, and personnel can change, requiring the form to be reviewed and possibly updated. Regular briefings and updates to the Job Hazard Analysis ensure that new risks are identified and communicated to all team members.

- Emergency procedures are common knowledge. Assuming that emergency procedures are common knowledge and don't require detailed discussion is risky. The Job Briefing form includes sections for emergency contacts and specific rescue procedures to ensure everyone knows exactly what to do in case of an incident. Details such as local hospital information, emergency phone numbers, and specific evacuation points are included for a reason; they save time and lives during critical moments. Discussing and documenting these procedures ensures that, in the event of an emergency, everyone is prepared.

Understanding these misconceptions can greatly increase the effectiveness of job briefings and the Routine Job Hazard Analysis process. By valuing the importance of these forms, teams can foster a safer and more informed working environment.

Key takeaways

Filling out and using the Job Briefing form is essential for maintaining safety and efficiency on construction projects. Here are four key takeaways to ensure its effectiveness:

- Comprehensive Completion: It's important to fill out the form thoroughly before starting any work. This includes detailing the job information, emergency procedures, tasks for the day, job site exposures, and hazard control measures. Doing so ensures that all aspects of the job are considered, and safety measures are in place.

- Emergency Preparedness: The emergency procedures section is critical. Make sure to list all emergency contact numbers, ensure the functionality of 911 systems via cell phone, and outline specific rescue procedures like fall protection and fire department contacts. This preparation can be crucial in case of an unforeseen event.

- Hazard Control Measures: Identifying potential hazards and implementing control measures is a key part of the job briefing. This includes the use of personal protective equipment (PPE), safety systems training, and the inspection of tools and equipment. Properly annotating these measures helps in minimizing risks associated with the job.

- Engagement and Acknowledgement: All affected personnel should be engaged in the job briefing process and sign off in Block 9 of the form. This ensures that everyone is informed about the job's specifics, understands the safety protocols, and acknowledges their role in maintaining a safe work environment.

By focusing on these key areas, teams can increase their awareness of potential hazards, ensure proper safety measures are in place, and foster a culture of safety and open communication on the job site.

Popular PDF Forms

Washington 4 H Record Book - Shapes a more meaningful and impactful 4-H experience through intentional record-keeping and reflection.

Owner Operator Tax Deductions Worksheet - Capitalize on tax deductible expenses specific to truck driving, ensuring no opportunity is missed.

Florida Highway Patrol Crash Reports - Totals three sections for multiple vehicles or non-motorists involved, allowing comprehensive documentation of larger incidents.