Blank Material Safety Sheet PDF Template

The Material Safety Data Sheet, often abbreviated as MSDS, is a comprehensive form critical in the world of chemical products, ensuring the safety and well-being of anyone who might come into direct or indirect contact with these substances. This form is meticulously structured into 16 distinct sections, each providing vital information that covers a broad spectrum of knowledge required to handle, store, and dispose of chemicals safely. From the basic identification details of the chemical product and its manufacturer found in Section 1, to the intricate details concerning its composition, hazards identification, and first aid measures cited in the subsequent sections, the MSDS plays a pivotal role. It not only informs about the physical and chemical properties of the substance in question but also delves into the legal and shipping information, emphasising the importance of regulatory adherence and safety precautions. The detailed ecological, disposal, and transport guidelines underscore the emphasis on environmental protection. Hence, this document serves as an indispensable tool for emergency responders, employers, and employees alike, facilitating a safer workplace and contributing to the broader goal of public health and environmental preservation.

Preview - Material Safety Sheet Form

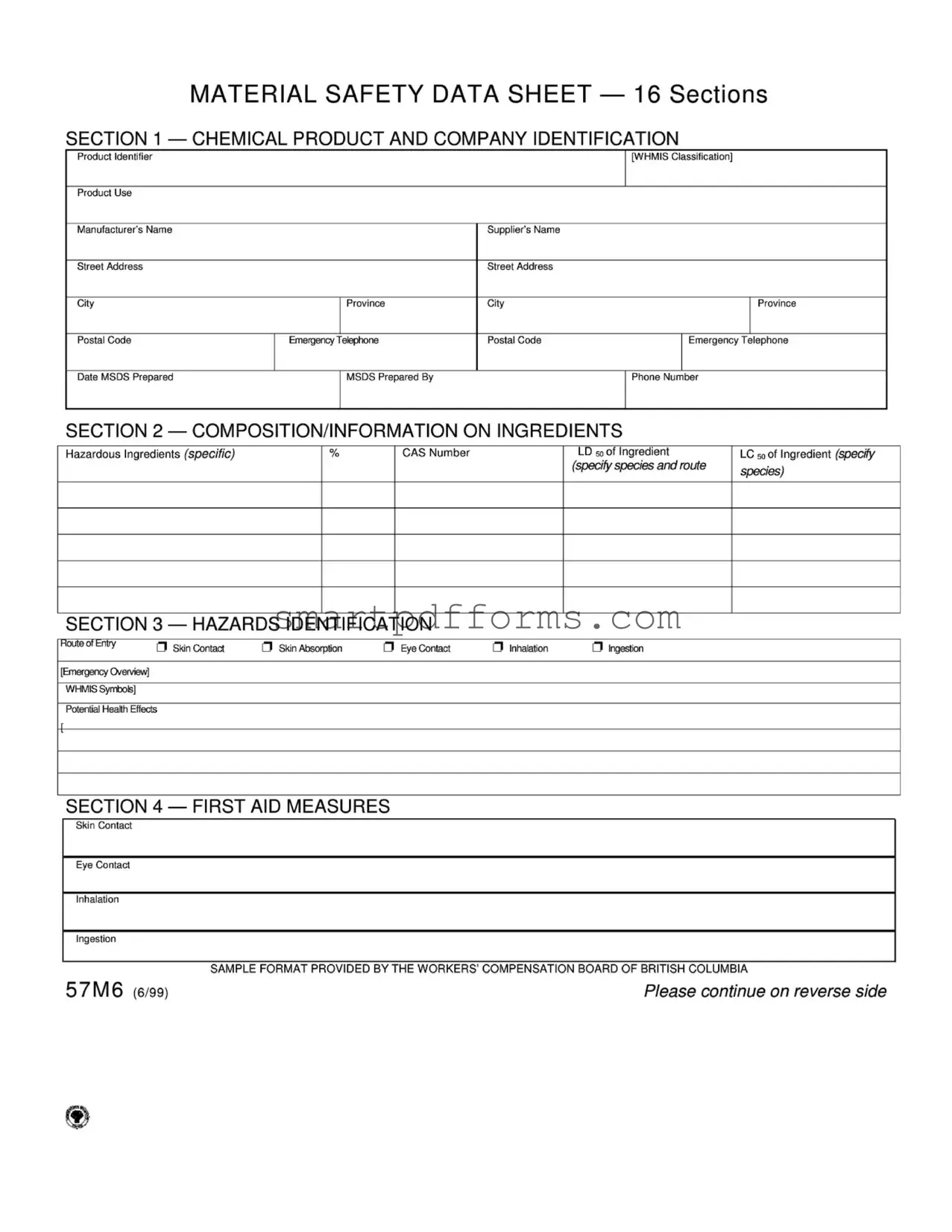

MATERIAL SAFETY DATA SHEET — 16 Sections |

||||

SECTION 1 — CHEMICAL PRODUCT AND COMPANY IDENTIFICATION |

|

|||

Product Identifier |

|

|

[WHMIS Classification] |

|

Product Use |

|

|

|

|

Manufacturer's Name |

|

Supplier’s Name |

|

|

Street Address |

|

Street Address |

|

|

City |

Province |

City |

|

Province |

Postal Code |

Emergency Telephone |

Postal Code |

Emergency Telephone |

|

Date MSDS Prepared |

MSDS Prepared By |

Phone Number |

|

|

SECTION 2 — COMPOSITION/INFORMATION ON INGREDIENTS |

|

|||

Hazardous Ingredients (specific) |

% |

CAS Number |

LD so of Ingredient |

LC so of Ingredient (specify |

|

|

|

(specify species and route |

species) |

|

|

|

|

|

SECTION 3 — HAZARDS IDENTIFICA1RON

О Skin Contact |

П Skin Absorption |

П Eye Contact |

П Inhalation |

П Ingestion |

[Emergency Overview]

WHMIS Symbols]

Potential Health Effects

SECTION 4 — FIRST AID MEASURES

5 7 M 6 (6/99) |

Please continue on reverse side |

Product

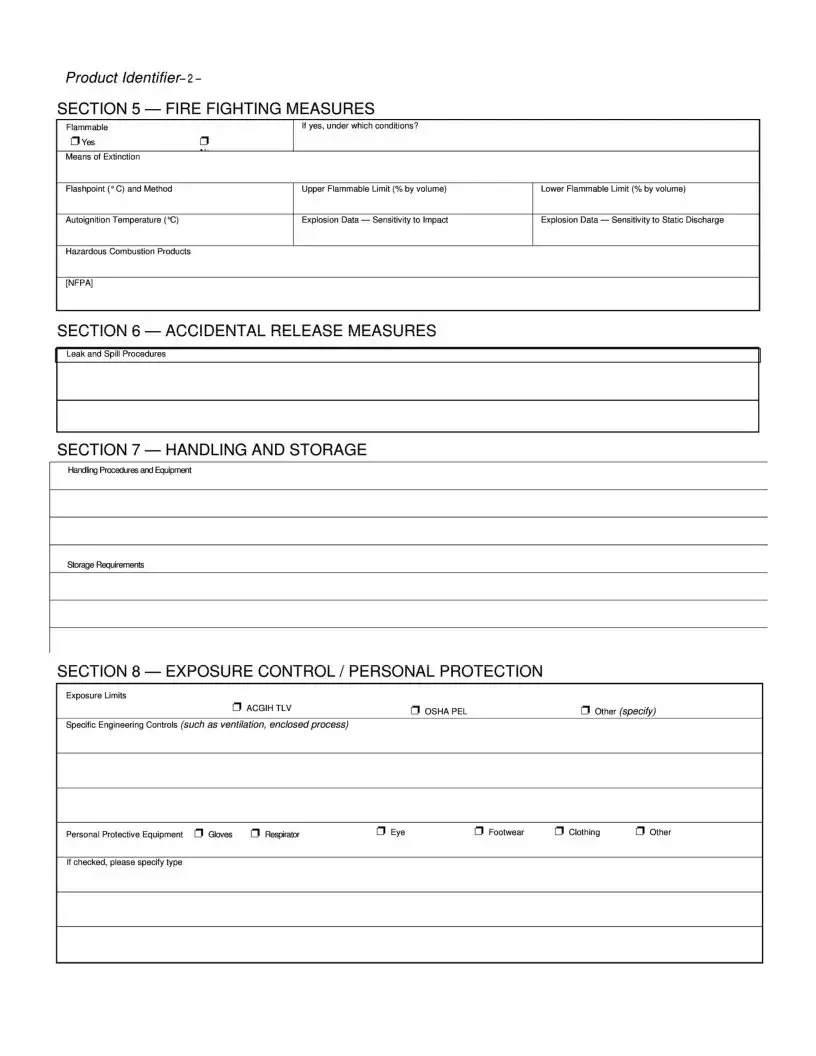

SECTION 5 — FIRE FIGHTING MEASURES

Flammable |

If yes, under which conditions? |

|

Yes |

|

|

Means of Extinction |

|

|

Flashpoint (°C) and Method |

Upper Flammable Limit (% by volume) |

Lower Flammable Limit (% by volume) |

Autoignition Temperature (°C) |

Explosion Data — Sensitivity to Impact |

Explosion Data — Sensitivity to Static Discharge |

Hazardous Combustion Products |

|

|

[NFPA] |

|

|

SECTION 6 — ACCIDENTAL RELEASE MEASURES

Leak and Spill Procedures

SECTION 7 — HANDLING AND STORAGE

SECTION 8 — EXPOSURE CONTROL / PERSONAL PROTECTION

Exposure Limits

ACGIH TLV |

0SHA pEL |

Д Other (Specify) |

Specific Engineering Controls (such as ventilation, enclosed process)

Personal Protective Equipment |

Gloves |

Respirator |

Eye |

Footwear |

Clothing |

Other |

If checked, please specify type

Product Identifiers -

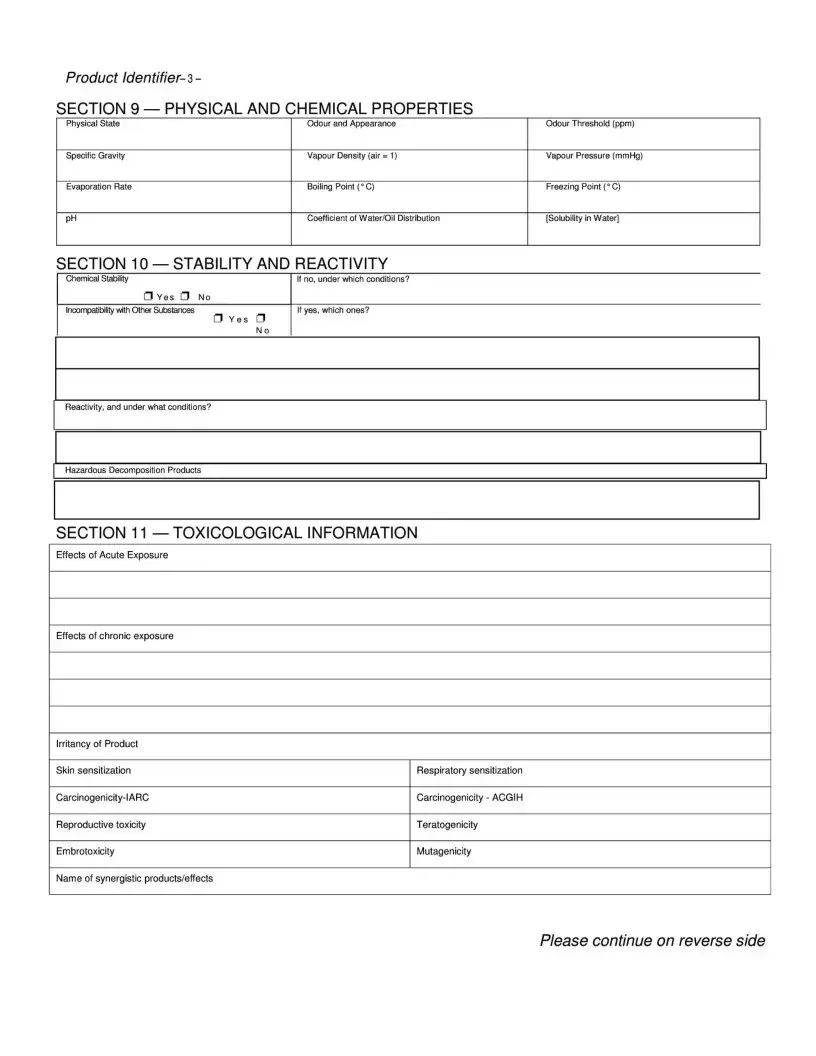

SECTION 9 — PHYSICAL AND CHEMICAL PROPERTIES

Physical State |

Odour and Appearance |

Odour Threshold (ppm) |

Specific Gravity |

Vapour Density (air = 1) |

Vapour Pressure (mmHg) |

Evaporation Rate |

Boiling Point (°C) |

Freezing Point (°C) |

pH |

Coefficient of Water/Oil Distribution |

[Solubility in Water] |

SECTION 10 — STABILITY AND REACTIVITY

Chemical Stability |

If no, under which conditions? |

О Yes П No

Incompatibility with Other Substances |

If yes, which ones? |

|

Yes |

|

N о |

Reactivity, and under what conditions?

Hazardous Decomposition Products |

| |

SECTION 11 — TOXICOLOGICAL INFORMATION

Effects of Acute Exposure

Effects of chronic exposure

Irritancy of Product |

|

Skin sensitization |

Respiratory sensitization |

Carcinogenicity - ACGIH |

|

Reproductive toxicity |

Teratogenicity |

Embrotoxicity |

Mutagenicity |

Name of synergistic products/effects |

|

Please continue on reverse side

Product Identifier- 4-

SECTION 12 — ECOLOGICAL INFORMATION

[Aquatic Toxicity]

SECTION 13 — DISPOSAL CONSIDERATIONS

Waste Disposal

SECTION 14

Special Shipping Information

TOG

[IMO]

PIN

[DOT]

[CAO]

SECTION 15 — REGULATORY INFORMATION

[WHMIS Classification] |

[OSHA] |

[SERA] |

[TSCA] |

This product has been classified in accordance with the hazard criteria of the

Controlled Products Regulations (CPR) and the MSDS contains all of the information required by CPR.

SECTION 16

Form Data

| Fact Name | Description |

|---|---|

| Form Structure | The Material Safety Data Sheet (MSDS) is organized into 16 detailed sections, providing comprehensive information from chemical identification to regulatory details. |

| Identification and Composition | Sections 1 and 2 detail the chemical product and company identification, including the product's usage and hazardous ingredients, aimed at ensuring clear and accessible information on chemical makeup. |

| Health and Safety Measures | Sections 3 to 8 cover hazards identification, first aid measures, fire fighting measures, accidental release measures, handling and storage, and exposure control/personal protection to ensure safe handling and emergency preparedness. |

| Governing Laws | Section 15 provides regulatory information, including classifications under the Workplace Hazardous Materials Information System (WHMIS), Occupational Safety and Health Administration (OSHA), and Toxic Substances Control Act (TSCA), showing compliance with multiple governing laws. |

Instructions on Utilizing Material Safety Sheet

Filling out a Material Safety Data Sheet (MSDS) is a critical task that ensures the safety of those who handle, transport, or use chemicals. It provides comprehensive details about the chemical product, its hazards, safe handling practices, and first aid measures. Following a step-by-step approach can simplify the process and ensure that all necessary information is accurately and thoroughly provided.

- Section 1: Chemical Product and Company Identification

- Enter the product identifier, product use, and WHMIS classification.

- List manufacturer’s name, address, city, postal code, province, and emergency telephone number.

- Include supplier's name, address, city, postal code, province, and emergency telephone number.

- Indicate the date the MSDS was prepared and provide contact information of the individual or department that prepared it.

- Section 2: Composition/Information on Ingredients

- Provide details on hazardous ingredients including their percentage, CAS number, LD50 (specifying species and route), and LC50 values.

- Section 3: Hazards Identification

- Mark the appropriate routes of exposure such as skin contact, inhalation, and ingestion.

- List potential health effects and emergency overview.

- Section 4: First-Aid Measures

- Detail the necessary first aid responses for various types of exposure (inhalation, ingestion, skin, and eye contact).

- Section 5: Fire-Fighting Measures

- Describe flammability, suitable extinguishing methods, flashpoint, autoignition temperature, hazardous combustion products, and explosive limits.

- Section 6: Accidental Release Measures

- Outline steps for dealing with leaks and spills, including emergency procedures and protective equipment requirements.

- Section 7: Handling and Storage

- Provide recommendations on safe handling practices and storage conditions.

- Section 8: Exposure Controls/Personal Protection

- List exposure limits, engineering controls, and specific personal protective equipment (PPE) such as gloves, respirators, and eye protection.

- Section 9: Physical and Chemical Properties

- Include information on physical state, specific gravity, pH, odour and appearance, and other relevant chemical properties.

- Section 10: Stability and Reactivity

- Detail information on chemical stability, incompatible materials, and hazardous decomposition products.

- Section 11: Toxicological Information

- Provide details on the effects of acute and chronic exposure, including specific health risks such as carcinogenicity or respiratory sensitization.

- Section 12: Ecological Information

- Give information regarding the chemical’s impact on aquatic life and the environment.

- Section 13: Disposal Considerations

- Describe appropriate disposal methods and any special handling instructions.

- Section 14: Transport Information

- Provide special shipping information, including classification details and any transport restrictions.

- Section 15: Regulatory Information

- List the product's classification under various regulations such as WHMIS, OSHA, and TSCA.

- Section 16: Other Information

- Include any additional remarks or relevant data not covered in the previous sections.

Completing each section of the MSDS with due diligence and attention to detail is essential. This ensures the safety and well-being of all individuals who may come into contact with the chemical, fulfilling both a legal and ethical responsibility.

Obtain Answers on Material Safety Sheet

What is a Material Safety Data Sheet (MSDS)?

A Material Safety Data Sheet (MSDS) is a document that provides information on the properties of potentially hazardous chemical products. It includes details about the chemical's composition, safety measures, first aid treatments, and risks. Manufacturers and suppliers often prepare these sheets to inform users about the safe handling, storage, and disposal of the substance.

Why is the MSDS important?

The MSDS is crucial because it contains vital safety information that protects workers and the environment from chemical hazards. It helps in the planning of safe handling and emergency procedures. Furthermore, it's a key document for compliance with legal and regulatory requirements related to occupational health and safety.

Who needs to use the MSDS?

- Employers: For ensuring workplace safety and compliance with regulations.

- Employees: For understanding the hazards and safe handling procedures of chemicals they work with.

- Emergency responders: For devising appropriate response actions in case of incidents involving chemicals.

- Health and Safety Officers: For developing safety programs and training materials.

What are the key sections of an MSDS?

The MSDS is divided into 16 sections, each covering different aspects of chemical safety information, including:

- Chemical product and company identification

- Composition/information on ingredients

- Hazards identification

- First aid measures

- Fire-fighting measures

- Accidental release measures

- Handling and storage

- Exposure controls/personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information

- Disposal considerations

- Transport information

- Regulatory information

- Other information

This comprehensive structure ensures that all essential safety aspects are addressed.

How should one act if they come into contact with a chemical listed on an MSDS?

Immediately refer to Sections 3 (Hazards Identification) and 4 (First Aid Measures) of the MSDS for the chemical. These sections provide instructions for immediate actions to take in case of skin contact, inhalation, ingestion, or eye exposure, such as rinsing affected areas with water or seeking medical attention.

Where should an MSDS be kept?

MSDSs should be accessible in areas where the chemicals are stored or used. Employers are responsible for ensuring that these documents are readily available to all employees who may be exposed to hazardous substances during their work.

Common mistakes

One common mistake is not filling out the product identifier section completely. This part of the form requires detailed information about the chemical product, including its name and any other identifying codes. Leaving this section incomplete can lead to confusion and misuse of the product.

Failing to specify the hazardous ingredients accurately is another significant error. The form asks for specific percentages, CAS numbers, and toxicological data (LD50, LC50) related to the ingredients. Incorrect or vague details can severely impact the safety and handling procedures of the chemical product.

The section on hazards identification is often overlooked. Marking the correct boxes and detailing the potential health effects, such as skin contact, inhalation, ingestion, etc., are crucial for informing users of the risks. Neglecting this section compromises the fundamental purpose of the Material Safety Data Sheet (MSDS), which is to safeguard users by providing essential safety information.

Inaccuracies in the first aid measures section can have dire consequences. This part of the form should clearly articulate immediate actions to take in the event of exposure or accidents involving the chemical product. Ambiguities or errors in this section could lead to improper first aid responses, exacerbating injuries or health impacts.

Finally, incorrect or missing information in the exposure control/personal protection section is a frequent oversight. This critical section outlines necessary personal protective equipment (PPE) and other safety measures needed to handle the chemical safely. Omitting details or providing erroneous information here can result in insufficient protection for users, increasing the risk of exposure and accidents.

Documents used along the form

When managing hazardous materials, the Material Safety Data Sheet (MSDS) is crucial but it's not the only document required for comprehensive safety and compliance. Several other forms and documents often accompany the MSDS to provide a full picture of the handling, exposure, and regulatory compliance related to hazardous materials. Here are seven key documents that are frequently used alongside the MSDS:

- Chemical Inventory Form: This document lists all chemicals stored or used in a facility. It provides a quick reference for what materials are on site and their quantities.

- Emergency Contact Information: A detailed list of internal and external contacts for emergency situations, including names, titles, and phone numbers for first responders, local hospitals, and poison control centers.

- Training Records: Documentation that employees have been trained on the proper handling and emergency procedures related to hazardous materials. This may include dates of training and specific content covered.

- Emergency and Fire Safety Plans: Detailed plans outlining the steps to be taken in the event of an emergency or fire, including evacuation routes, locations of safety equipment, and procedures for containing hazardous materials.

- Job Safety Analysis (JSA) or Hazard Assessment Forms: Documents identifying potential hazards associated with specific jobs or tasks and outlining measures to minimize risks.

- Exposure Records: Detailed logs of incidents where employees were exposed to hazardous materials, including the type of material, level of exposure, duration, and any medical treatment administered.

- Inspection Reports: Records of regular inspections for safety equipment, storage areas for hazardous materials, and workplace areas where hazardous materials are used, to ensure compliance with safety standards.

Together with the MSDS, these documents form a comprehensive safety and compliance protocol for managing hazardous materials in the workplace. Each document plays a role in ensuring that employees are informed, protected, and prepared for emergencies, and that the organization complies with local, state, and federal regulations.

Similar forms

Occupational Safety and Health Administration (OSHA) Hazard Communication Standard (HCS) Documents: Like the Material Safety Data Sheet (MSDS), these documents are vital for workplace safety. They contain detailed information about the chemicals present in the workplace, including their hazards, handling practices, and emergency measures, mirroring the structured detail found in MSDS to promote safe working conditions.

Product Safety Data Sheets (PSDS): These documents are similar to MSDS because they provide critical information on the safe use of products, including chemical composition, hazards, safe handling, and emergency procedures. The PSDS serves a similar purpose by ensuring users are well-informed about the products they are using, reflecting the comprehensive nature of the information found in MSDS.

Technical Data Sheets (TDS): These sheets resemble sections of the MSDS, particularly those related to physical and chemical properties (like Section 9), stability and reactivity (Section 10), and sometimes toxicological information (Section 11). TDS documents provide detailed specifications and performance characteristics of materials and products, supporting informed use and handling.

Transportation of Dangerous Goods (TDG) Documentation: These documents share similarities with Sections 14 and 15 of the MSDS, which cover transport information and regulatory information. They include critical safety information necessary for the safe shipping and handling of hazardous materials, outlining requirements for labels, placards, and shipping documents to prevent accidents.

Chemical Risk Assessment Reports: Similar to the health hazard and ecological information provided in Sections 11 and 12 of the MSDS, these reports analyze and document the potential risks chemicals pose to health and the environment. They detail exposure limits, toxicological effects, and provide guidelines on exposure control and personal protection, paralleling the purpose of an MSDS to protect users and the environment from chemical hazards.

Dos and Don'ts

When filling out a Material Safety Data Sheet (MSDS), providing detailed and accurate information is crucial to ensure the safe handling, storage, and use of chemicals. Here are five key things you should and shouldn't do:

What You Should Do:

Be precise: Include exact measurements and specific details about chemical properties, hazards, and safe handling practices.

Consult updated sources: Use the most recent scientific data and regulatory standards to ensure your information is current.

Clarify precautions: Clearly outline safety measures, first aid procedures, and emergency actions to minimize risks.

Use simple language: Avoid technical jargon to make the MSDS accessible to all employees, regardless of their scientific background.

Review and update regularly: Periodically assess the MSDS for accuracy and make necessary updates to reflect changes in chemical usage or safety regulations.

What You Shouldn't Do:

Exclude information: Don't omit details about any known hazards or safety practices associated with the chemical.

Assume knowledge: Avoid assuming that users have a background in chemistry or safety procedures.

Use vague language: Avoid ambiguous terms that can lead to misinterpretation of the safety requirements or chemical properties.

Overlook sections: Don't skip any of the 16 sections in the MSDS; each provides critical information for the safe handling and use of the chemical.

Delay updates: Avoid postponing updates to the MSDS, as this can lead to the use of outdated and potentially unsafe information.

Misconceptions

When it comes to the Material Safety Data Sheet (MSDS), there are several common misconceptions that can lead to confusion or misunderstanding. Clearing up these misconceptions is crucial for ensuring workplace safety and compliance with regulations.

Misconception 1: MSDSs are only necessary for chemicals that are labeled as hazardous.

This is not true. The reality is that an MSDS must be provided for any chemical substance or mixture, regardless of whether it is considered hazardous. This ensures that all potential risks are communicated effectively.

Misconception 2: All sections of an MSDS are equally important for every user.

While all sections contain valuable information, the relevance may vary depending on the user's role. For instance, emergency responders might focus more on sections dealing with first aid measures and fire-fighting measures, whereas employees handling the chemicals regularly might prioritize exposure controls and personal protection.

Misconception 3: An MSDS is only useful in the event of an emergency.

Although MSDSs are critical in emergency situations, they also play a key role in everyday safety and health management, providing information on proper handling, storage, and use of chemicals to prevent accidents and exposures.

Misconception 4: MSDS information is static and never changes.

Chemical properties don't change, but our understanding of their effects on health or the environment can evolve. Additionally, regulations and safety recommendations are periodically updated. Therefore, MSDSs are updated to reflect the most current information available.

Misconception 5: All MSDSs follow the same format.

While there is a standardized 16-section format recommended for consistency, the depth and style of information presented can vary significantly between manufacturers and products. Always review each MSDS carefully.

Misconception 6: If a product is common, you don’t really need to read its MSDS.

Even the most common products can have risks associated with their use, especially in large quantities or under specific conditions. Familiarity should not replace diligence in safety practices, making it important to review the MSDS for every product, regardless of its perceived commonality.

Key takeaways

Understanding the Material Safety Data Sheet (MSDS) is crucial for anyone handling, storing, or disposing of hazardous chemicals. Here are five key takeaways to ensure compliance and enhance safety in the workplace:

- Comprehensive Product and Company Identification: The MSDS starts with detailed information about the chemical product and the manufacturing company. This includes the product identifier, product use, manufacturer’s details, and emergency contact numbers. It's essential for quick identification and response in case of an emergency.

- Understanding Hazards and Precautions: Sections 2 and 3 focus on the composition of the chemical and hazard identification, respectively. They list hazardous ingredients, including their concentrations and potential health effects. This information is vital for assessing risks and implementing safety measures to protect workers.

- First Aid Measures and Fire Fighting: Quick and efficient action can reduce the severity of injuries or damage in an emergency. Section 4 outlines first aid measures for various types of exposure, while Section 5 details firefighting techniques, throwing light on flammability, means of extinction, and conditions that could exacerbate the fire hazard.

- Accidental Release and Handling Instructions: Knowing how to react to spills or leaks (Section 6) and understanding proper handling and storage requirements (Section 7) are imperative. These sections help prevent accidents and ensure chemicals are managed safely.

- Regulatory Information and Safety Measures: Lastly, sections 8 and 15 provide guidelines on exposure controls, personal protective equipment, and regulatory information. Compliance with these instructions not only ensures worker safety but also adherence to legal and regulatory obligations.

Altogether, the MSDS serves as a comprehensive guide for managing chemical hazards effectively. Familiarity with these sheets and adherence to their guidelines are fundamental steps towards ensuring a safe working environment for all employees.

Popular PDF Forms

Property Maintenance Invoice Template - Equipped with a section for wind direction and speed to account for additional challenges faced during service.

Lic38 - Telephone contact information, both home and mobile, must be provided, ensuring the Department can reach the applicant as needed.