Blank Reefer Inspection PDF Template

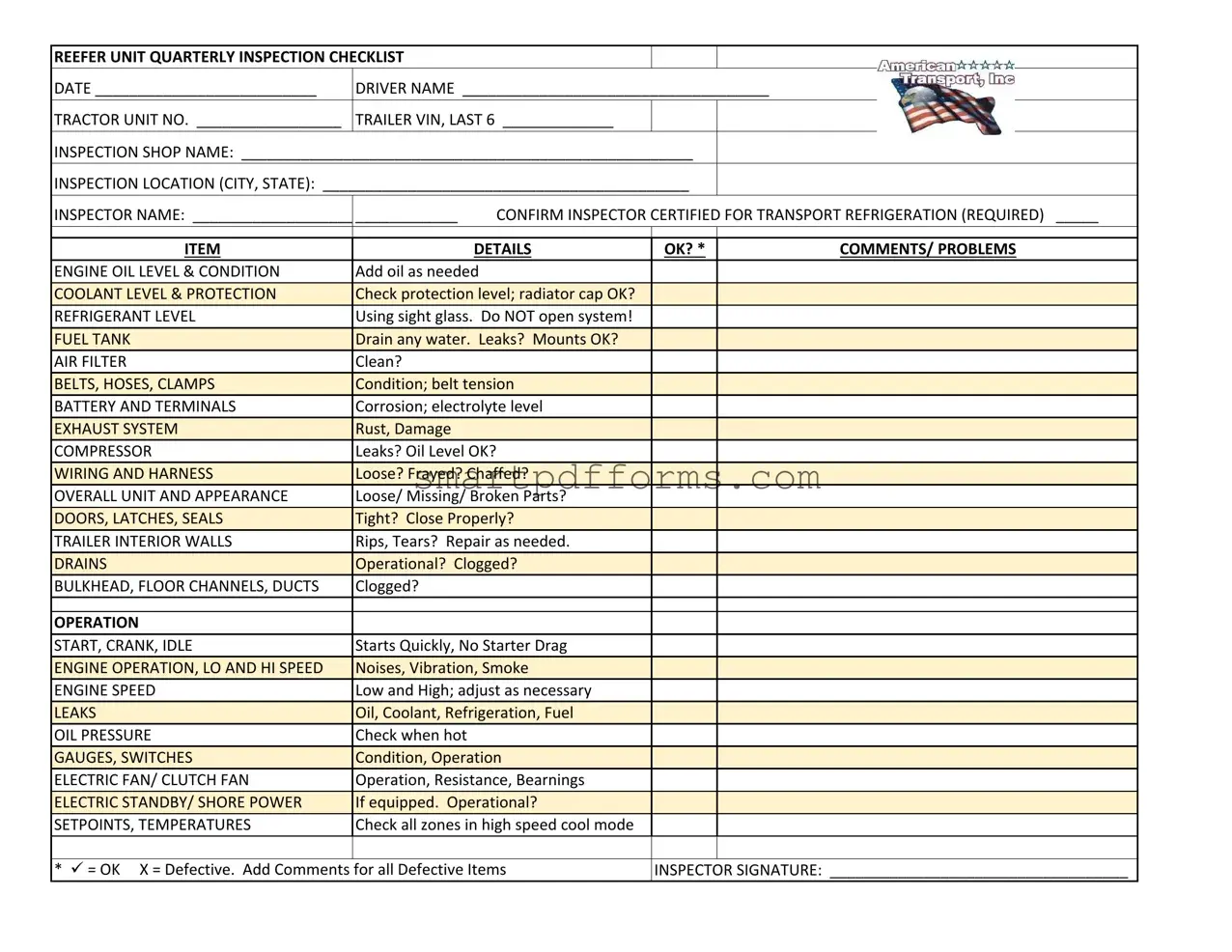

In the constantly evolving landscape of commercial transportation, the integrity of refrigerated cargo is paramount, necessitating rigorous inspection protocols to ensure perishables reach their destinations in optimal condition. The Reefer Inspection form plays a critical role in this process, serving as a comprehensive checklist to assess the operational readiness of refrigerated units on a quarterly basis. Detailed within the form are sections for recording the date, driver's name, tractor and trailer identification, along with the inspection location and the inspector’s credentials, verifying their qualification for assessing transport refrigeration units. It meticulously covers the inspection of key components such as engine oil and coolant levels, refrigerant levels, fuel tanks, and the cleanliness and condition of air filters. Additionally, it evaluates the structural and functional integrity of belts, hoses, clamps, battery terminals, the exhaust system, and compressor, while also scrutinizing the wiring, harness, unit appearance, and interior condition of the trailer. The checklist extends to operational aspects like the response of doors, latches, seals, the trailer’s interior walls, drains, and the performance of the engine across various parameters. Notably, the form requires inspectors to note the condition of items, marking them as satisfactory or flagging defects with comments, ensuring a thorough audit of the unit’s ability to maintain specified temperature setpoints crucial for the safe transport of perishable goods. This structured approach not only enhances safety and compliance but also underpins the logistics sector's commitment to delivering quality.

Preview - Reefer Inspection Form

REEFER UNIT QUARTERLY INSPECTION CHECKLIST

|

DATE __________________________ |

DRIVER NAME ____________________________________ |

|

|

||||||||||

|

TRACTOR UNIT NO. _________________ |

TRAILER VIN, LAST 6 _____________ |

|

|

|

|

||||||||

|

INSPECTION SHOP NAME: _____________________________________________________ |

|

|

|

||||||||||

|

INSPECTION LOCATION CITY, STATE : ___________________________________________ |

|

|

|

||||||||||

|

INSPECTOR NAME: ___________________ |

____________ |

CONFIRM INSPECTOR CERTIFIED FOR TRANSPORT REFRIGERATION REQUIRED _____ |

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

ITEM |

|

|

|

DETAILS |

|

|

|

OK? * |

|

COMMENTS/ PROBLEMS |

|

||

|

ENGINE OIL LEVEL & CONDITION |

Add oil as |

eeded |

|

|

|

|

|

|

|

|

|

||

|

COOLANT LEVEL & PROTECTION |

Che k p ote tio le el; |

adiato |

ap OK? |

|

|

|

|

||||||

|

REFRIGERANT LEVEL |

Usi |

|

g sight glass. Do NOT ope |

syste ! |

|

|

|

|

|||||

|

FUEL TANK |

D ai |

a y |

ate . Leaks? Mou ts OK? |

|

|

|

|

||||||

|

AIR FILTER |

Clea |

? |

|

|

|

|

|

|

|

|

|

|

|

|

BELTS, HOSES, CLAMPS |

Co |

ditio |

; elt te sio |

|

|

|

|

|

|

|

|

||

|

BATTERY AND TERMINALS |

Co |

|

osio |

; ele t olyte le el |

|

|

|

|

|

|

|||

|

EXHAUST SYSTEM |

Rust, Da |

age |

|

|

|

|

|

|

|

|

|

||

|

COMPRESSOR |

Leaks? Oil Le el OK? |

|

|

|

|

|

|

|

|

||||

|

WIRING AND HARNESS |

Loose? F ayed? Chaffed? |

|

|

|

|

|

|

|

|||||

|

OVERALL UNIT AND APPEARANCE |

Loose/ Missi g/ B oke |

Pa ts? |

|

|

|

|

|

||||||

|

DOORS, LATCHES, SEALS |

Tight? Close P ope ly? |

|

|

|

|

|

|

|

|

||||

|

TRAILER INTERIOR WALLS |

Rips, Tea s? Repai |

as |

eeded. |

|

|

|

|

|

|||||

|

DRAINS |

Ope atio |

al? Clogged? |

|

|

|

|

|

|

|

|

|||

|

BULKHEAD, FLOOR CHANNELS, DUCTS |

Clogged? |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OPERATION |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

START, CRANK, IDLE |

Sta ts Qui kly, No Sta te |

D ag |

|

|

|

|

|

||||||

|

ENGINE OPERATION, LO AND HI SPEED |

Noises, Vi |

atio , S |

oke |

|

|

|

|

|

|

|

|||

|

ENGINE SPEED |

Lo |

|

a d High; adjust as |

|

e essa y |

|

|

|

|

||||

|

LEAKS |

Oil, Coola |

t, Ref ige atio |

, Fuel |

|

|

|

|

||||||

|

OIL PRESSURE |

Che k he hot |

|

|

|

|

|

|

|

|

|

|||

|

GAUGES, SWITCHES |

Co ditio , Ope atio |

|

|

|

|

|

|

|

|

|

|||

|

ELECTRIC FAN/ CLUTCH FAN |

Ope atio |

, Resista |

e, Bea |

i |

gs |

|

|

|

|

||||

|

ELECTRIC STANDBY/ SHORE POWER |

If e uipped. Ope atio al? |

|

|

|

|

|

|

||||||

|

SETPOINTS, TEMPERATURES |

Che k all zo es i high speed |

ool ode |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

* = OK X = Defe ti e. Add Co e ts |

fo |

all Defe ti e Ite |

s |

|

|

|

|

INSPECTOR |

SIGNATURE: ___________________________________ |

|

|||

Form Data

| Fact Name | Description |

|---|---|

| Form Purpose | The Reefer Inspection form is used for performing quarterly checks on refrigeration units to ensure they are functioning correctly and safely. |

| Key Information Collected | The form collects data such as date, driver name, tractor unit number, trailer VIN, inspection shop name, location, and inspector name. |

| Inspector Qualification Confirmation | It is required that the form confirms the inspector is certified for transport refrigeration inspections. |

| Inspection Items | Includes a checklist covering engine oil, coolant, refrigerant levels, fuel tank, air filter, belts, hoses, clamps, battery and terminals, exhaust system, compressor, wiring, unit appearance, doors, trailer interior, drains, bulkhead, floor channels, ducts, operation, leaks, oil pressure, gauges, switches, and fan/clutch operation. |

| Assessment Criteria | Items are marked as OK or defective, with an option to add comments for all defective items. |

| Importance of Inspection | Regular inspection is crucial for preventing breakdowns, prolonging the unit's lifespan, ensuring safety, and complying with legal standards. |

| Governance | While this template is generic, specific states may have additional laws governing the transportation and operation of refrigeration units on the road. For state-specific forms, local transportation and safety regulations would apply. |

Instructions on Utilizing Reefer Inspection

Filling out the Reefer Inspection Form is an essential step for ensuring the proper maintenance and operational standards of refrigerated transportation units. This process, designed to be comprehensive, aims at identifying any shortcomings or mechanical issues that could impact the unit's effectiveness or safety. It's a routine part of the maintenance schedule, undertaken quarterly, that helps in preempting potential failures. Proper completion of the form is crucial in documenting the health of the unit and planning subsequent actions if any issues are identified. Following these step-by-step instructions will make the process straightforward and ensure no detail is overlooked.

- On the top line marked "DATE", enter the current date to document when the inspection takes place.

- Fill in the "DRIVER NAME" with the full name of the individual operating the vehicle.

- Under "TRACTOR UNIT NO.", note the identification number of the tractor unit for record purposes.

- Input the last six digits of the "TRAILER VIN" to specify which trailer is being inspected.

- In the "INSPECTION SHOP NAME" field, write the full name of the shop or facility conducting the inspection.

- For "INSPECTION LOCATION CITY, STATE", specify the city and state where the inspection occurs.

- Identify the inspector by filling in "INSPECTOR NAME", ensuring accountability and traceability.

- Make sure to tick the box next to "CONFIRM INSPECTOR CERTIFIED FOR TRANSPORT REFRIGERATION" to affirm the inspector's qualifications.

- Proceed to review each item on the checklist. For each, indicate the condition by checking the appropriate box under "OK?" If the item is satisfactory, mark with a check (√), and if defective, mark with an "X".

- In the "COMMENTS/ PROBLEMS" section adjacent to each item, provide details, comments, or describe the problems identified during the inspection. Be specific to ensure clarity and to facilitate any needed repairs or adjustments.

- For each "ITEM DETAILS" listed, such as "ENGINE OIL LEVEL & CONDITION", "COOLANT LEVEL & PROTECTION", through to "SETPOINTS, TEMPERATURES", assess and accurately report the current condition based on the guidelines provided in the form.

- Once all items have been reviewed and the form is fully completed, the "INSPECTOR SIGNATURE" field at the bottom of the document must be signed by the inspector, thereby validating the inspection.

After completing the Reefer Inspection Form, the next step involves reviewing all noted defects and issues. Each problem identified needs to be assessed further to determine the appropriate corrective action, ranging from immediate repairs to scheduling follow-up inspections or services. This follow-up action is crucial for maintaining the reefer unit in optimal condition, ensuring it operates safely and efficiently while minimizing downtime and preventing cargo from being compromised.

Obtain Answers on Reefer Inspection

-

What is the purpose of the Reefer Inspection form?

The Reefer Inspection form is designed to ensure that the refrigeration units on trailers, commonly referred to as reefers, are operating correctly and are in good physical condition. It helps in maintaining the safety and efficiency of the transported goods by regularly checking components such as engine oil, coolant levels, refrigerant levels, and the structural integrity of the trailer itself. Regular inspections can identify potential issues early, preventing cargo spoilage and reducing costly breakdowns.

-

Who is required to fill out the Reefer Inspection form?

This form is typically filled out by an inspector who is certified in transport refrigeration. It may be filled out at an inspection shop or at any location designated for such inspections. The driver's name, along with tractor and trailer identification details, are recorded, ensuring that the specific unit being inspected is properly documented. This process ensures that the inspection is thorough and conducted by someone with the necessary expertise.

-

How often should the Reefer Inspection be completed?

The form denotes that the inspection is to occur on a quarterly basis. This regular, scheduled maintenance is crucial for preemptively identifying and rectifying potential issues that could lead to the malfunction of the reefer unit. Consistent inspections help keep the reefer units in optimal working condition, thus protecting the cargo during transport.

-

What happens if defects are found during the inspection?

When defects are identified during the inspection, the form provides a section for comments and problems next to each checklist item. This allows the inspector to detail any issues found and recommend necessary repairs or adjustments. Defective items are marked accordingly, prompting immediate attention. It is crucial that all identified defects are addressed promptly to ensure the reefer unit returns to efficient operational status and can safely transport perishable goods.

-

Is the Reefer Inspection form different from a general vehicle inspection?

Yes, the Reefer Inspection form is specifically targeted towards the refrigeration unit on a trailer, rather than the vehicle as a whole. While a general vehicle inspection focuses on the roadworthiness and safety features of the vehicle itself, the Reefer Inspection is concerned with the operational integrity and physical condition of the refrigeration system. This includes checks on temperatures, engine operation for both low and high speed, coolant levels, and structural components specific to maintaining the required refrigeration for transported goods.

Common mistakes

When it comes to maintaining the efficiency and safety of refrigerated transport units, also known as reefers, filling out the quarterly inspection form correctly is crucial. However, there are common pitfalls many encounter during this process. Here's a closer look at these mistakes:

Not Verifying Inspector Qualifications: It's imperative to confirm if the inspector is certified for transport refrigeration. Skipping this step might result in oversight of critical issues.

Overlooking the Details: Missing vital information, such as the tractor unit number or trailer's VIN, can invalidate the entire form.

Ignoring to List Problems: Failing to add specific comments on issues found during the inspection. A mere check might not convey the extent of the problems.

Incorrectly Assessing Oil and Fluid Levels: Errors in checking the engine oil level, coolant protection level, and refrigerant level can lead to significant mechanical failures.

Overlooking Exterior Inspection: Neglecting to inspect and report on the overall unit appearance, including missing or broken parts, can result in overlooking potential external damages.

Improper Evaluation of the Cooling System: Not conducting a thorough inspection of belts, hoses, clamps, and the compressor might miss critical wear and tear.

Not Testing Operational Functionality: Skipping or incorrectly assessing operational checks, such as start, crank, idle, engine operation at low and high speed, can result in undetected performance issues.

Failing to Check Electrical Systems: Forgetting to inspect the battery, terminals, wiring, and harness for signs of corrosion, looseness, or fraying might lead to unexpected power failures.

Attention to detail is key when filling out the Reefer Inspection Form. By avoiding these common mistakes, you can ensure a thorough and accurate assessment of the reefer unit, safeguarding against potential failures and ensuring the integrity of the transported goods.

Documents used along the form

Understanding the essential forms and documents that are often used in conjunction with the Reefer Inspection form is crucial for maintaining compliance and ensuring the upkeep of refrigerated transport units. These documents not only facilitate smooth operations but also help in meeting legal and safety standards. Below is a compilation of other forms and documents frequently utilized alongside the Reefer Inspection form.

- Bill of Lading (BOL): This legal document between the shipper and the carrier details the type, quantity, and destination of the goods being carried. It serves as a receipt of freight services, a contract of carriage, and a document of title.

- Temperature Record Log: A vital document for monitoring and recording the temperature inside the reefer unit throughout the transportation process. This ensures that the cargo is maintained at the required temperature settings as per the goods' preservation needs.

- Delivery Receipt: This document is provided to the receiver of the cargo, detailing the condition of the goods upon arrival and confirming that the delivery has been made. It is crucial for verifying that the goods were delivered in good condition.

- Pre-trip Inspection Report: A report filled out by the driver before embarking on a trip. It includes an inspection of the vehicle and the reefer unit to ensure that everything is in working order, thereby preventing potential issues during transit.

- Maintenance and Repair Log: This log keeps a record of all maintenance work and repairs carried out on the reefer unit. It is important for ensuring the unit remains in optimal condition and for tracking the history of repairs for future reference.

- Driver’s Hours of Service Log: This document is mandated by regulatory bodies to ensure drivers do not exceed the stipulated hours of service, contributing to road safety. It records the daily driving hours and rest periods of the driver.

These documents, when used alongside the Reefer Inspection form, ensure that all aspects of refrigerated transport are monitored, from the condition of the reefer unit to the safety and legality of the transportation process. Keeping accurate and detailed records is not only vital for compliance but also for the integrity of the goods transported, ultimately contributing to the efficiency and reliability of the service provided.

Similar forms

Vehicle Maintenance Checklist: Similar to the Reefer Inspection form, this document ensures that all parts of a vehicle, like a car or truck, are in good working order. They both focus on regular inspection to maintain safety and efficiency, covering areas like oil level, coolant protection, and battery condition.

Pre-Trip Inspection Form: This form is used by drivers before starting a journey to ensure the vehicle is safe to drive. It checks for similar items as the Reefer Inspection form, such as tire condition, engine performance, and lighting, to prevent any mechanical failures on the road.

Equipment Safety Checklist: Used in various industries, this checklist verifies that all equipment operates safely and within regulatory standards. It mirrors the Reefer Inspection form by examining components like machinery cleanliness, operational status, and safety features to mitigate hazards.

Quality Control Checklist for Manufacturing: This checklist ensures that products meet quality standards before leaving the manufacturing plant. It's similar to the Reefer Inspection form as both involve thorough inspections to identify defects or issues, focusing on areas like material condition, assembly, and operational functionality.

Air Conditioning Service Form: This form focuses on the inspection and maintenance of air conditioning units. Like the Reefer Inspection form, it checks refrigerant levels, filters, and overall unit condition to ensure the system is working efficiently and effectively.

Home Inspection Form: Though used in real estate, this form shares the concept of inspecting for safety, functionality, and aesthetics with the Reefer Inspection form. It covers structural elements, HVAC systems, plumbing, and electrical systems to outline any necessary repairs or maintenance.

Fire Safety Inspection Checklist: Aimed at preventing fire hazards, this checklist reviews fire safety equipment, escape routes, and hazard materials. It is akin to the Reefer Inspection form in its goal to identify and rectify potential risks, ensuring the safety of all occupants and the operational integrity of fire safety devices.

Dos and Don'ts

When it comes to filling out a Reefer Inspection form, it's essential to pay close attention to detail and follow some key dos and don'ts to ensure the process is done correctly and efficiently. Below are lists of what you should and shouldn't do during this process.

Dos:

Ensure that all information is accurate and up-to-date, including the date, driver name, tractor unit number, and trailer VIN.

Confirm that the inspection shop name and location (city, state) are clearly written and correct.

Check each item on the checklist thoroughly and mark them with a "" if OK or "X" if defective, adding comments for all defective items to provide context.

Verify that the inspector's name is legibly written, and confirm the inspector is certified for transport refrigeration as required.

Don'ts:

Don't skip any sections of the form. Every item detail is crucial for a comprehensive inspection.

Don't guess on any of the inspection items. If unsure, ask a certified professional or refer to the manufacturer's guidelines.

Don't forget to check the "Required" box to confirm the inspector's certification status. This is a critical step that validates the entire inspection.

Don't rush through the inspection. Taking your time to accurately assess each component will ensure a safe and functional reefer unit.

Misconceptions

When reviewing or discussing the Reefer Inspection form, several misunderstandings often come up. It's essential to clear up these misconceptions to ensure proper maintenance and compliance procedures are followed.

- Only mechanical issues are important. Many believe the form exclusively focuses on mechanical aspects, such as engine oil level or compressor function. However, the inspection also covers cleanliness and structural integrity, such as the condition of trailer interior walls and doors.

- Inspections are optional. Some might think these inspections are not strictly required, but they're critical for safety and compliance. They ensure the refrigeration unit operates efficiently, maintains temperature, and doesn't pose a hazard on the road.

- The condition of the exterior isn't scrutinized. There's a common misconception that the inspection doesn't consider the unit's overall appearance and external components. Yet, the checklist includes items like doors, latches, seals, and overall unit appearance to assess for any damage that could impact performance.

- Reefer inspections are only about preventing food spoilage. While maintaining the correct temperature to avoid spoilage is a significant concern, the inspection also focuses on safety issues like leaks, battery condition, and proper operation of all systems to prevent any road incidents.

Understanding these aspects of the Reefer Inspection form is crucial for drivers and fleet operators to ensure their units are not only compliant but also safe and efficient on the road.

Key takeaways

When filling out a reefer inspection form, it's essential to follow a structured approach for accuracy and comprehensiveness. Here are key takeaways to ensure the process goes smoothly:

- Familiarize yourself with all sections of the form before starting the inspection to understand what details are required.

- Date, driver information, and vehicle specifics are crucial for record-keeping and tracking the inspection history.

- Ensure the inspector's certification for handling transport refrigeration units is verified and documented on the form.

- Item checks must be marked as OK if they meet the standards or highlighted for issues with comments or problems noted for further actions.

- Regular checks on engine oil, coolant levels, and refrigerant levels are necessary to prevent malfunction and ensure efficiency.

- Inspection should cover not only the mechanical parts like belts, hoses, clamps, and the battery but also the physical condition of the unit including doors, latches, seals, and the interior condition of the trailer.

- Operational checks such as start, crank, idle, engine operation at low and high speeds, and leaks are critical to ensure the unit's performance is optimal.

- Special attention should be given to the exhaust system, compressor, wiring, and the electrical system to identify potential hazards or failures.

- Finally, confirming the functionality of optional features like electric standby or shore power (if equipped), and making sure all temperatures and setpoints are correctly checked in high-speed cool mode.

Making sure each part of the checklist is completed and every defective item is noted with comments ensures the reefer unit remains in top condition. This not only helps in maintaining the quality of transported goods but also in extending the lifespan of the refrigeration unit.

Popular PDF Forms

How to Get on Shark Tank - Dive into an environment where innovation meets expertise, presenting your invention to seasoned investors on the national stage, aiming to secure pivotal funding and strategic guidance.

Mvr-615 - North Carolina residents with a valid driver's license can use the MVR-615 to affirm their insurance eligibility for vehicle registration.