Blank Sling Inspection Record PDF Template

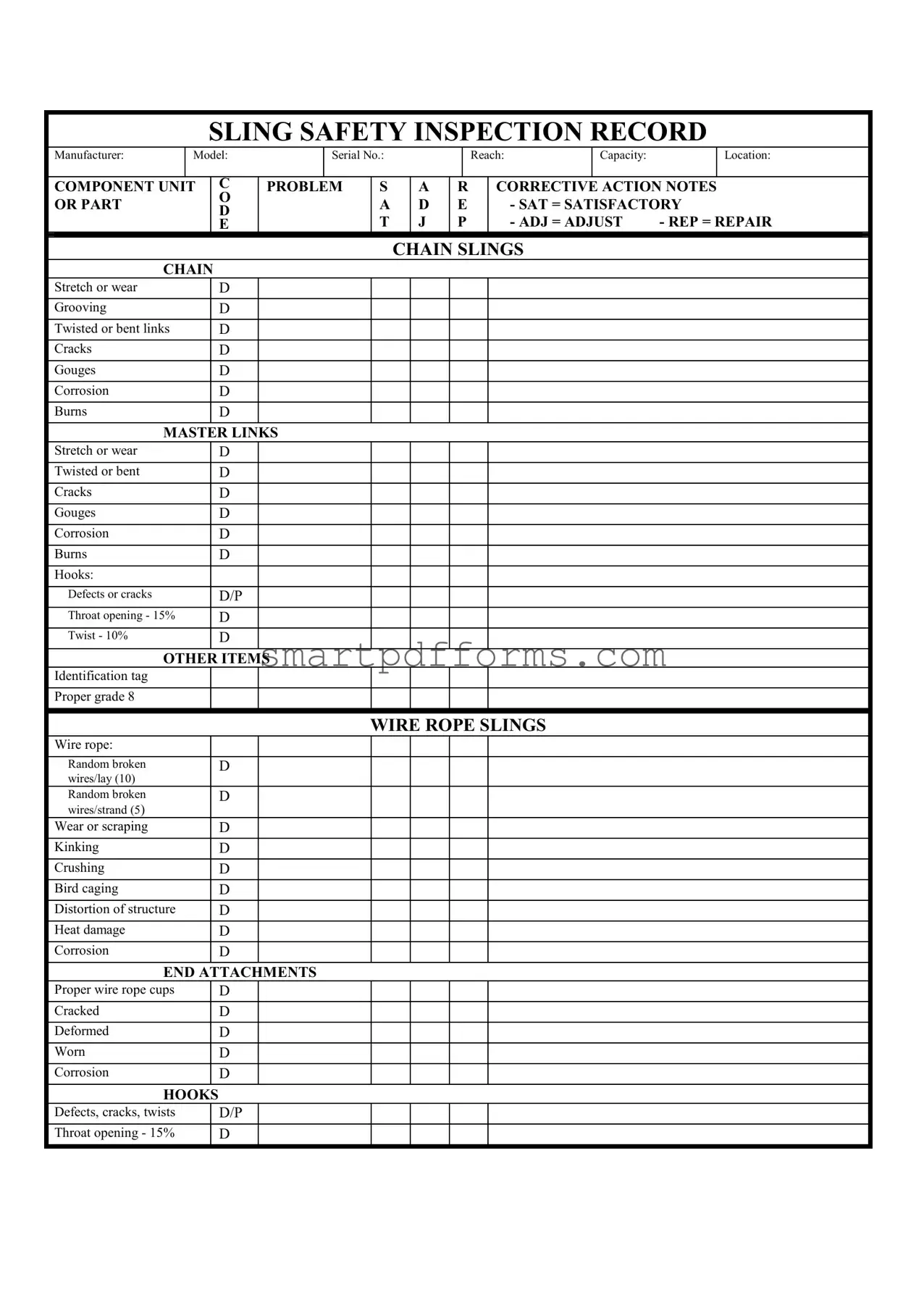

Maintaining the safety and reliability of lifting equipment is crucial in various industries, ensuring operations run smoothly and safeguarding the health of those on site. The Sling Inspection Record form serves as a vital tool in this quest for workplace safety, meticulously documenting the condition of slings used in lifting operations. By detailing aspects like the manufacturer, model, the serial number, and capacity of each sling, this form aids in tracking essential equipment specifications. It doesn't just stop at identifying details; the form delves into a comprehensive inspection covering everything from chain slings, wire rope slings, synthetic web slings, to metal, mesh slings, identifying potential hazards such as wear, corrosion, or damage that could compromise safety. This includes inspection of chain stretches, twisted links, hook defects, wire wear or kinking, among others, followed by recommended corrective actions like adjustments or repairs, essentially guiding maintenance practices. Furthermore, the Sling Inspection Record includes space for inspector remarks and has a structured system for logging inspections daily, monthly, or periodically as recommended, all underscoring the form's critical role in ensuring lifting operations are conducted safely, efficiently, and in compliance with safety standards.

Preview - Sling Inspection Record Form

SLING SAFETY INSPECTION RECORD

|

Manufacturer: |

Model: |

|

|

|

|

|

|

COMPONENT UNIT |

C |

|

|

O |

||

|

OR PART |

|

|

|

|

D |

|

|

|

|

|

|

|

|

E |

|

Serial No.: |

|

|

|

Reach: |

|

Capacity: |

|

Location: |

|||

|

|

|

|

|

|

|

|

|

|

|

||

PROBLEM |

S |

A |

R |

|

CORRECTIVE ACTION NOTES |

|||||||

|

|

A |

D |

E |

|

|

- SAT = SATISFACTORY |

|||||

|

|

T |

J |

P |

|

|

- ADJ = ADJUST |

- REP = REPAIR |

||||

CHAIN SLINGS

CHAIN

Stretch or wear |

D |

|

|

|

|

|

Grooving |

D |

|

|

|

|

|

Twisted or bent links |

D |

|

|

|

|

|

|

|

|

|

|

|

|

Cracks |

D |

|

|

|

|

|

|

|

|

|

|

|

|

Gouges |

D |

|

|

|

|

|

|

|

|

|

|

|

|

Corrosion |

D |

|

|

|

|

|

Burns |

D |

|

|

|

|

|

MASTER LINKS |

||||||

Stretch or wear |

D |

|

|

|

|

|

|

|

|

|

|

|

|

Twisted or bent |

D |

|

|

|

|

|

|

|

|

|

|

|

|

Cracks |

D |

|

|

|

|

|

|

|

|

|

|

|

|

Gouges |

D |

|

|

|

|

|

Corrosion |

D |

|

|

|

|

|

Burns |

D |

|

|

|

|

|

|

|

|

|

|

|

|

Hooks: |

|

|

|

|

|

|

|

|

|

|

|

|

|

Defects or cracks |

D/P |

|

|

|

|

|

Throat opening - 15% |

D |

|

|

|

|

|

Twist - 10% |

D |

|

|

|

|

|

OTHER ITEMS |

||||||

Identification tag |

|

|

|

|

|

|

Proper grade 8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

WIRE ROPE SLINGS

Wire rope: |

|

|

|

|

|

|

|

Random broken |

|

D |

|

|

|

|

|

wires/lay (10) |

|

|

|

|

|

|

|

Random broken |

|

D |

|

|

|

|

|

wires/strand (5) |

|

|

|

|

|

|

|

Wear or scraping |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

Kinking |

|

D |

|

|

|

|

|

Crushing |

|

D |

|

|

|

|

|

Bird caging |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

Distortion of structure |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

Heat damage |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

Corrosion |

|

D |

|

|

|

|

|

END ATTACHMENTS |

|

|

|

||||

Proper wire rope cups |

|

D |

|

|

|

|

|

Cracked |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

Deformed |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

Worn |

|

D |

|

|

|

|

|

Corrosion |

|

D |

|

|

|

|

|

HOOKS |

|

|

|

|

|

|

|

Defects, cracks, twists |

|

D/P |

|

|

|

|

|

Throat opening - 15% |

|

D |

|

|

|

|

|

COMPONENT UNIT |

C |

|

O |

||

OR PART |

||

D |

||

|

||

|

E |

|

|

|

PROBLEM

S |

A |

R |

CORRECTIVE ACTION NOTES |

|

A |

D |

E |

- SAT = SATISFACTORY |

|

T |

J |

P |

- ADJ = ADJUST |

- REP = REPAIR |

|

|

|

|

|

SYNTHETIC WEB SLINGS

WEBBING

Acid or caustic burns |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Melting or charring |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Snags |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Punctures |

|

D |

|

|

|

|

|

|

Tears |

|

D |

|

|

|

|

|

|

Cuts |

|

D |

|

|

|

|

|

|

Broken or worn stitches |

|

D |

|

|

|

|

|

|

FITTINGS |

|

|

|

|||||

Cracked |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Deformed |

|

D |

|

|

|

|

|

|

Worn |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Corrosion |

|

D |

|

|

|

|

|

|

HOOKS |

|

|

|

|

|

|

|

|

Defects or cracks |

|

D/P |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Throat openings - 15% |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Twist - 10% |

|

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

METAL, MESH SLINGS

MESH |

|

|

|

|

|

|

|

Broken weld |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Broken brazed joint |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Reduction in diameter |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Lack of flexibility |

D |

|

|

|

|

|

|

Handle: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Distortion of either handle |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Proper splices |

D |

|

|

|

|

|

|

Abnormal wear |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Powdered fiber between |

D |

|

|

|

|

|

|

strand |

|

|

|

|

|

|

|

Broken or cut fibers |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Variations in size |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Discoloration or rotting |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Distortion of hardware |

D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REMARKS

REMARKS

1. Inspection code intervals:

1. Inspection code intervals:

|

D |

daily |

|

|

|

|

M |

monthly |

|

|

|

|

P |

periodically |

1 to 12 month intervals, or as specifically recommended by the manufacturer. |

|

|

|

|

|

|

|

|

Date of Safety Inspection:

Signature of Inspector:

Form Data

| Fact Name | Description |

|---|---|

| Form Purpose | This form is used for recording the safety inspection of slings. |

| Documented Components | It documents the condition of chain slings, wire rope slings, synthetic web slings, metal, and mesh slings. |

| Identifying Details | Details such as Manufacturer, Model, Serial No., Reach, Capacity, and Location are recorded for each sling. |

| Evaluation Symbols | Problems and corrective actions are coded with symbols: SAT (Satisfactory), ADJ (Adjust), and REP (Repair). |

| Inspection Categories | The form categorizes potential issues, like stretch, wear, corrosion, and structural damages, for comprehensive evaluation. |

| Specific Issues to Check | It specifies particular issues to check for, such as grooving, twisted or bent links in chains, and conditions like acid burns on webbing. |

| Inspection Intervals | Inspection codes indicate when inspections should occur: daily (D), monthly (M), or periodically (1 to 12-month intervals). |

| Endorsement | The form requires the signature of the inspector and the date of the safety inspection. |

| Governing Laws | The form does not specify state-specific laws, but sling inspections are generally governed by OSHA regulations in the U.S. |

| Remedial Actions | Corrective actions are suggested for identified problems, promoting timely repairs or adjustments. |

Instructions on Utilizing Sling Inspection Record

Ensuring the safety and reliability of slings in the workplace is critical. A Sling Inspection Record serves as a detailed checklist that helps identify any potential issues with slings that could compromise their safety. This process not only helps in maintaining a safe working environment but also extends the lifespan of the slings by addressing and rectifying problems early. To complete this form, follow these detailed steps to ensure that each aspect of the sling's condition is thoroughly examined and documented.

- Begin by entering the Manufacturer and Model of the sling at the top of the form.

- Fill in the Serial No., Reach, Capacity, and Location of the sling being inspected to uniquely identify it and detail its specifications.

- Under COMPONENT UNIT OR PART, tick the appropriate box to indicate the condition of various parts of the sling. Use the codes provided:

- SAT for Satisfactory

- ADJ for Adjust

- REP for Repair

- Inspect the Chain Slings section for any stretch or wear, grooving, twisted or bent links, cracks, gouges, corrosion, or burns. Mark the appropriate box to indicate the findings.

- Examine the Master Links, noting any stretch or wear, twisting or bending, cracks, gouges, corrosion, or burns. Record the inspection results accordingly.

- Check Hooks for defects or cracks, improper throat opening, or twist percentage. Detail the observations in the provided boxes, indicating 'D' for defects and 'P' for percentage problems.

- Under Wire Rope Slings, inspect and mark the condition of the wire rope, end attachments, and hooks based on the same codes provided.

- For Synthetic Web Slings, assess the webbing and fittings for any damage such as acid or caustic burns, melting, charring, snags, punctures, and more. Record any findings.

- Inspect Metal, Mesh Slings for signs of broken welds or brazed joints, reduction in diameter, lack of flexibility, and other specified issues. Note any problems identified.

- Under REMARKS, provide any additional observations or notes that could be useful for further assessment or future reference.

- Specify the Inspection code intervals by marking 'D' for daily, 'M' for monthly, and 'P' for periodically (1 to 12 month intervals or as specifically recommended by the manufacturer).

- Finally, enter the Date of Safety Inspection and have the Signature of Inspector at the bottom of the form to validate the inspection.

Completing the Sling Inspection Record accurately is essential for effective sling maintenance and safety compliance. It ensures that any potential hazards are identified and corrected, promoting a safer working environment.

Obtain Answers on Sling Inspection Record

-

What is the purpose of a Sling Safety Inspection Record?

The Sling Safety Inspection Record is a vital document used to ensure the safety and integrity of various types of slings used in lifting operations. Its purpose is to record the condition of each component of the sling, identify any problems, and note the corrective actions taken. Regular inspections help prevent accidents by ensuring slings are in good working condition.

-

What types of slings are covered in this inspection form?

This form covers inspections for chain slings, wire rope slings, synthetic web slings, and metal mesh slings. For each type, specific components such as chains, wire rope, webbing, fittings, and hooks are examined for various defects or wear and tear.

-

How are sling problems categorized in the form?

Problems with slings are categorized using symbols and abbreviations to indicate the type of issue identified. The key symbols include “D” for detection of a problem and whether an item is “SAT” (Satisfactory), needs “ADJ” (Adjustment), or requires “REP” (Repair). This categorization helps in quick understanding and decision-making regarding corrective actions.

-

What specific defects or conditions are checked during an inspection?

The inspection looks for various specific defects or conditions such as stretch, wear, grooving, twisted or bent links, cracks, gouges, corrosion, and burns among others for chains. For wire rope slings, inspectors check for broken wires, wear, kinking, and heat damage among others. Similar checks are applicable for synthetic web and metal mesh slings focusing on issues like acid burns, snags, broken welds, and distortion of hardware.

-

How often should sling inspections take place?

Sling inspections should occur at different intervals depending on the sling’s use and condition. The form indicates inspections can be “D” daily, “M” monthly, “P” periodically from 1 to 12 month intervals, or as specifically recommended by the manufacturer. This flexibility ensures that slings are inspected frequently enough to maintain safety without causing undue downtime or inconvenience.

-

What is the significance of the inspection code intervals mentioned in the form?

The inspection code intervals (daily, monthly, periodically) provide a guideline for the frequency of inspections. This helps in planning and ensuring slings are checked regularly based on their usage intensity and exposure to wear and tear. Adhering to these intervals is crucial for maintaining the safety of lifting operations.

-

Who is responsible for carrying out the sling inspections and filling out the form?

Qualified personnel, typically trained inspectors or safety officers, are responsible for carrying out the sling inspections. These individuals must have the necessary knowledge and experience to identify defects and assess the overall condition of the sling. The inspector’s signature at the end of the form is required, signifying that the inspection was completed and documented according to the defined standards.

Common mistakes

Overlooking the importance of filling in all sections of the form, particularly those that detail the condition of various sling components. These sections are crucial for assessing the sling's safety and operational status.

Failing to provide detailed descriptions of problems identified during the inspection. Simply checking a box to indicate a problem is not enough; specifics about the issue can guide necessary corrective actions.

Omitting the date of the safety inspection. The date is essential for tracking the frequency of inspections and ensuring that the sling is inspected at appropriate intervals, as recommended by the manufacturer.

Not using the inspection code intervals (D for daily, M for monthly, P for periodically) correctly. This might lead to inconsistencies in maintenance schedules and potentially overlook critical inspection needs.

Skipping the signature of the inspector section. This is a key oversight since the signature verifies that the inspection was conducted by a qualified individual and validates the form’s contents.

Incorrectly identifying the sling's components, such as confusing wire rope slings with synthetic web slings. Accurate identification ensures the correct assessment criteria are applied.

Overlooking the "CORRECTIVE ACTION" details. When problems are found, it is vital to specify whether adjustment (ADJ) or repair (REP) is needed, or if the sling passes inspection (SAT).

Failing to check off appropriate descriptions under the "PROBLEM" column. Without accurately marking problems like “stretch or wear,” “cracks,” or “corrosion,” it’s challenging to track the condition over time.

Overlooking the need to inspect all listed items, including less common components like "END ATTACHMENTS" or the condition of the "Identification tag.” Each part plays a crucial role in the sling's overall safety and functionality.

Not providing clear notes in the "NOTES" section when observations or anomalies don't fit neatly into the checklist. Detailed notes can provide context and assist in future inspections or audits.

In summary, careful and thorough completion of the Sling Safety Inspection Record is essential for ensuring the continued safety and functionality of slings used in operations. Attention to details, like those outlined above, helps prevent accidents and extends the life of these critical lifting tools.

Documents used along the form

When it comes to keeping a safe and compliant workplace, especially where equipment like slings are involved, it's crucial to have a thorough documentation and inspection process. The Sling Safety Inspection Record serves as a foundational piece of this process, ensuring that all components of a sling are inspected and maintained properly. However, this form is often part of a larger collection of documents that help manage and guarantee the safety and integrity of lifting devices. To maintain a high level of safety and compliance, the following documents are typically used in conjunction with the Sling Safety Inspection Record.

- Equipment Maintenance Log: This document tracks all maintenance activities performed on lifting equipment. It includes details such as the date of maintenance, the nature of any repairs or adjustments, the name of the person who performed the maintenance, and when the next maintenance check is due. This log helps ensure that all equipment is regularly maintained and kept in good working order.

- Lifting Equipment Operation Manual: A comprehensive guide that provides essential information about the operation, limitations, and safety precautions of the sling and other lifting devices. It includes manufacturer's instructions on how to correctly use the equipment, thereby reducing the risk of accidents due to operator error.

- Incident and Accident Report Forms: These forms are used to document any incidents or accidents that occur during sling operations. The reports include detailed information about what happened, when and where it occurred, who was involved, and any injuries or damages that resulted. Keeping accurate records of incidents and accidents is critical for identifying potential risks and implementing measures to prevent future occurrences.

- Training Records and Certifications: These documents verify that personnel involved in using, inspecting, and maintaining slings and other lifting equipment have received proper training and are certified to perform their duties. These records are vital for compliance purposes and ensuring that all operations are carried out safely and effectively by qualified individuals.

Each document plays a significant role in reinforcing the effectiveness of the Sling Safety Inspection Record, forming a comprehensive safety management system. Together, they contribute to a safer work environment by ensuring that equipment is properly maintained, operated by trained personnel, and any issues are promptly and accurately addressed. Ensuring these documents are up to date and easily accessible is fundamental to managing workplace safety and compliance effectively.

Similar forms

Vehicle Inspection Report: Similar to the Sling Inspection Record, a Vehicle Inspection Report documents the condition of various components of a vehicle to ensure it meets safety and operational standards. It includes checks for wear, damage, and the need for adjustments or repairs, paralleling the examination of slings for defects like stretching, wear, and corrosion.

Aircraft Maintenance Log: This log tracks the maintenance history of an aircraft, similar to how the Sling Inspection Record tracks sling inspections. Both documents record problems, corrective actions, and the condition of equipment, focusing on maintaining safety and compliance with regulatory standards.

Construction Equipment Checklist: Similar to sling inspections, this checklist ensures that construction equipment is safe and operable. It covers inspections for wear, damage, and functional integrity, mirroring the assessments for chains, webbings, and fittings in sling safety inspections.

Elevator Safety Inspection Report: This report documents the condition and safety of elevator components, akin to the Sling Inspection Record's focus on lifting equipment. Both identify issues like wear, damage, and the efficacy of corrective actions to ensure ongoing safety in operations.

Fire Safety Equipment Inspection Form: Like the Sling Inspection Record, this form ensures that fire safety equipment meets safety standards, checking for defects, operational efficiency, and the need for repairs or adjustments. Both are crucial for preventing accidents and ensuring safety in emergency situations.

Electrical System Inspection Report: This report assesses the condition and safety of electrical systems, similar to how sling safety inspections evaluate the integrity of lifting equipment. Both documents aim to identify and rectify potential hazards before they lead to accidents.

Crane Inspection Record: Much like sling inspections, crane inspections assess the safety and functionality of cranes, including checks for wear, damage, and structural integrity. These records are essential for verifying that lifting operations can be conducted safely and efficiently.

Personal Protective Equipment (PPE) Checklist: This checklist ensures that PPE is in good condition, functioning properly, and provides adequate protection, similar to the way sling inspections ensure the safety and integrity of slings for lifting operations.

Industrial Pressure Vessel Inspection Report: This report inspects the condition of pressure vessels to prevent accidents, akin to sling inspections focusing on lifting safety. It includes checks for corrosion, damage, and structural integrity, ensuring equipment is safe for use.

Dos and Don'ts

When filling out the Sling Inspection Record form, it’s imperative to ensure accuracy and completeness to maintain safety standards and compliance. Below are the dos and don'ts to guide you through the process.

Do:

- Review the manufacturer's guidelines before inspecting each sling to ensure compliance with specific safety and maintenance instructions.

- Inspect every component listed on the form, including chain slings, wire rope slings, synthetic web slings, and metal, mesh slings, for a thorough evaluation.

- Use the inspection codes accurately (SAT for satisfactory, ADJ for adjust, REP for repair) to indicate the condition of each component clearly.

- Record any defects found during the inspection in detail, specifying the type of problem, such as stretch or wear, cracks, or corrosion, to facilitate appropriate corrective action.

- Sign and date the form upon completion of the inspection to authenticate the record and ensure accountability.

- Take immediate corrective action for any problems identified during the inspection to prevent accidents and maintain the safety of workers.

- Maintain a regular inspection schedule as recommended by the manufacturer, noting the intervals on the form (D for daily, M for monthly, P for periodically).

Don't:

- Skip any sections of the form, even if they seem irrelevant at first glance, as each component's integrity is crucial for overall safety.

- Ignore minor defects thinking they might not affect the sling's performance; every issue should be recorded and assessed for safety.

- Forget to check the identification tag and ensure that it's legible and securely attached to the sling, as its information is critical.

- Assume all slings of the same type have the same inspection criteria; always refer to the form and the manufacturer's recommendations for each specific model and material.

- Rely on visual inspection alone for parts that require measurement (e.g., throat opening, twist percentage), as accuracy is key to identifying potential hazards.

- Underestimate the importance of documenting the condition of hooks and end attachments, as they are critical points of failure.

- Delay documentation or corrective action, as this may lead to unsafe conditions and potential legal issues in case of accidents.

Misconceptions

When dealing with a Sling Inspection Record form, several misconceptions often arise. Understanding these misconceptions can help ensure that sling operations are both safe and compliant. Here is a list of six common misconceptions:

- All sling types are inspected the same way. Different slings, such as chain, wire rope, synthetic web, and metal mesh, have unique inspection criteria outlined in the form. Each type requires attention to specific problems and corrective actions.

- A visual inspection is all that is needed. While visual inspection is crucial, it's not solely sufficient. The inspection process also involves checking for functional damage, such as stretch, wear, or corrosion, which may not always be immediately visible.

- If there's no visible damage, the sling is safe to use. Some types of damage, like internal wear in wire ropes or microscopic cracks in hooks, may not be visible but can significantly impact the sling’s safety. Therefore, more thorough inspection techniques may sometimes be necessary.

- The "Inspection code intervals" are just guidelines. The inspection intervals marked (D, M, P) are not mere suggestions but should be strictly followed to maintain safety standards. These intervals are set based on the manufacturer's recommendations and safety regulations.

- Any defects found are reasons to discard the sling immediately. While severe defects may necessitate removing a sling from service, the form also allows for corrective actions like adjustment or repair. The decision to retire a sling should be based on the type and extent of damage.

- Record-keeping is optional. Keeping a detailed record of each inspection, including the date, findings, and inspector’s signature, is a critical part of sling management. These records are not just for administrative purposes but are crucial for ensuring ongoing safety and compliance with regulations.

Understanding the correct procedures and requirements for sling inspection and documentation can help prevent accidents and ensure the longevity of the equipment. Misconceptions about the Sling Inspection Record form can lead to unsafe lifting practices, but accurate knowledge and adherence to the guidelines can contribute significantly to workplace safety.

Key takeaways

Filling out and using the Sling Inspection Record form requires attention to detail and an understanding of the specific inspection codes and requirements. Here are five key takeaways:

- It is crucial to accurately document the manufacturer, model, serial number, reach, capacity, and location of the sling. This information ensures that the sling can be correctly identified and tracked for future inspections.

- Understand the inspection codes used on the form: SAT (Satisfactory), ADJ (Adjust), and REP (Repair), which are essential for categorizing the condition of each component or part of the sling. Accurate classification helps in maintaining the safety and integrity of the sling.

- Inspect each component of the sling, such as chain slings, wire rope slings, synthetic web slings, and metal mesh slings, for specific types of damage or wear. This includes looking for stretch, wear, gouges, cracks, corrosion, and any form of deformation or damage that might compromise the sling's integrity.

- Special attention should be given to hooks and end attachments, checking for defects, cracks, twists, and appropriate throat opening percentages. These parts are critical to the safe operation of the sling and must be thoroughly inspected for any signs of damage or excessive wear.

- The form includes a section for recording corrective actions taken and any additional notes. This is vital for maintaining a history of the sling's condition and the maintenance work performed. It also helps in planning future inspections and identifying when a sling should be removed from service.

Finally, the inspection interval code—D (daily), M (monthly), P (periodically, from 1 to 12-month intervals or as recommended by the manufacturer)—is an essential part of the form, ensuring that the sling is inspected according to the required standards and frequencies for safety.

Popular PDF Forms

Section 504 Plan - An essential aspect of the form is the emphasis on instructional accommodations, ensuring that learning materials are accessible.

Near Miss Accident Examples - Identified instances of unsecured high-velocity fans in operational areas, posing a risk of injury from objects being blown around.

Sc Real Estate Law - Outlines the responsibilities of the seller to provide a marketable title and the process of deed delivery at closing.