Blank Tractor Checklist PDF Template

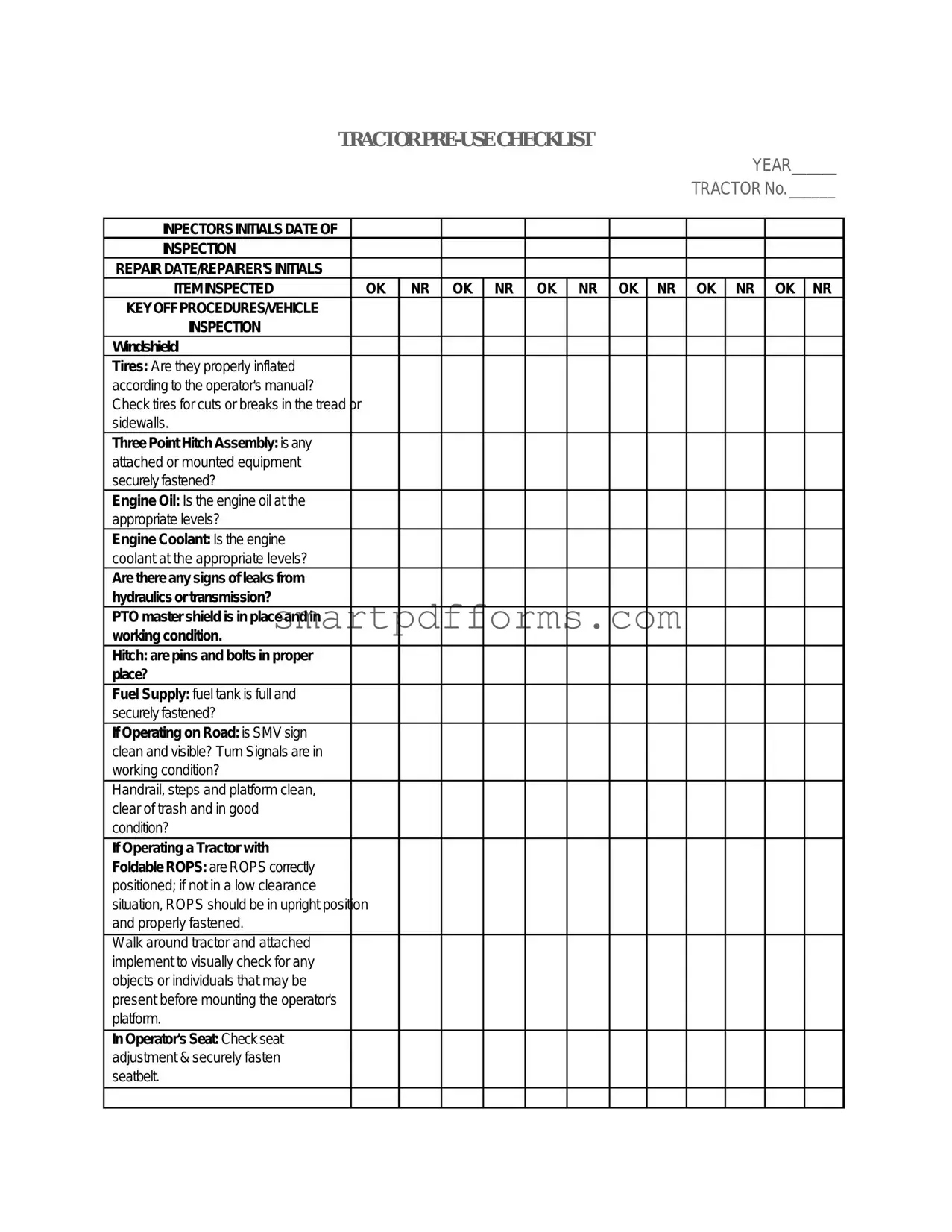

Ensuring the safety and operational efficiency of a tractor requires routine inspections before use, for which the Tractor Checklist form is an essential tool. This comprehensive form is designed to guide inspectors through a pre-use evaluation, covering a wide array of critical checkpoints to assess the tractor's condition. It includes assessments of key off procedures, such as inspecting the windshield, tires for proper inflation and signs of wear, and the secure fastening of the three-point hitch assembly. The checklist goes further to evaluate the engine oil and coolant levels, the condition of the PTO master shield, fuel supply, hitch integrity, and the cleanliness and visibility of the SMV sign when operating on roads. Additionally, it ensures turn signals, handrails, steps, and platforms are in good condition and that ROPS are appropriately positioned and secured. The form also prompts a walkthrough to identify potential hazards before operation. Once in the operator's seat, the inspector checks the seat adjustment, seatbelt fastening, instrument gauges, standard equipment functionality including lights and horn, and engine running procedures such as windshield wiper, brakes, parking brake, and hoist operations. This meticulous approach, documented with the inspector's initials and the date of inspection, ensures that any items requiring repair are identified and addressed promptly, thereby maintaining a safe working environment and upholding operational standards.

Preview - Tractor Checklist Form

TRACTOR

|

YEAR______ |

|

TRACTORNo.______ |

INPECTORSINITIALSDATEOF |

|

INSPECTION |

|

REPAIRDATE/REPAIRER'SINITIALS |

|

ITEMINSPECTED |

OK NR OK NR OK NR OK NR OK NR OK NR |

KEYOFFPROCEDURES/VEHICLE |

|

INSPECTION |

|

Windshield

Tires: Are they properly inflated according to the operator's manual?

Check tires for cuts or breaks in the tread or sidewalls.

Three Point Hitch Assembly: is any attached or mounted equipment securely fastened?

Engine Oil: Is the engine oil at the appropriate levels?

Engine Coolant: Is the engine coolant at the appropriate levels?

Are there any signs of leaks from hydraulicsortransmission?

PTO master shield is in place and in working condition.

Hitch: are pins and bolts in proper place?

Fuel Supply: fuel tank is full and securely fastened?

If Operating on Road: is SMV sign clean and visible? Turn Signals are in working condition?

Handrail, steps and platform clean, clear of trash and in good condition?

If Operating a Tractor with Foldable ROPS: are ROPS correctly positioned; if not in a low clearance situation, ROPS should be in upright position and properly fastened.

Walk around tractor and attached implement to visually check for any objects or individuals that may be present before mounting the operator's platform.

In Operator's Seat: Check seat adjustment & securely fasten seatbelt.

KEYONPROCEDURES

Checkgaugesandinstruments: Oil and battery lights are working properly?

Engine Temperature gauge is in working condition?

Hour Meter is in working condition?

StandardEquipment:

Steering is in working condition? Front, Tail, Brake, and Turn signal lights are in working condition? Horn is working properly?

ENGINERUNNINGPROCEDURES

StandardEquipment: Windshield wiper is working properly?

Brakes are working properly? Parking Brake is in working condition?

Hoist Operation is in working Condition?

Check all other items listed in operator'smanualas recommended.

NR= Needs Repair

If the tractor is found to be unsafe, the condition must be reported immediately to the supervisor and get repaired.

Form Data

| Fact Name | Description |

|---|---|

| Content Scope | The Tractor Pre-Use Checklist includes inspections of key off procedures/vehicle inspection, key on procedures, and engine running procedures. |

| Inspection Items | Items inspected range from tires, engine oil, engine coolant, and fuel supply, to safety features like the PTO master shield, hitch assembly, handrail condition, and the positioning of ROPS (Roll-Over Protective Structure). |

| Operational Checks | Operational checks include gauges and instruments, standard equipment functionality like steering, lights, horn, and critical operation needs such as brakes, parking brake, and hoist operation. |

| Safety Measures | The checklist emphasizes safety through checks like the presence and condition of the SMV (Slow Moving Vehicle) sign, seatbelt security, turn signals, ROPS positioning, and ensuring the area around the tractor is clear before operation. |

| Governing Laws and Regulations | While the checklist itself does not specify governing laws, compliance with it supports adherence to OSHA's agricultural operations standards and various state-specific safety regulations regarding agricultural machinery operation. |

Instructions on Utilizing Tractor Checklist

When operating a tractor, safety is paramount. To ensure a tractor is in good working condition, a pre-use checklist must be diligently completed. This not only helps in identifying any issues that may pose a risk during operation but also contributes to the tractor's longevity. The Tractor Pre-Use Checklist form is designed to be a comprehensive guide through this important process. The following steps will walk you through how to fill out the form properly.

- Start by entering the Year and Tractor Number at the top of the form.

- Fill in the Inspector's Initials and the Date of Inspection in the designated spaces.

- For each item listed under KEY OFF PROCEDURES / VEHICLE INSPECTION, inspect the tractor thoroughly and mark OK if the item is in good condition or NR (Needs Repair) if it is not.

- Ensure to check the windshield, tires, three-point hitch assembly, engine oil, engine coolant, hydraulic or transmission leaks, PTO master shield, hitch, fuel supply, SMV sign, turn signals, handrail, steps, platform, and ROPS as listed.

- Conduct a walk-around inspection of the tractor and any attached implements to ensure no objects or individuals are in the vicinity before proceeding.

- Once inside the operator's seat, verify the seat adjustment and securely fasten the seatbelt.

- Proceed to the KEY ON PROCEDURES section. Check and confirm the operation of gauges, instruments, steering, lights, and horn, and mark the checklist accordingly.

- With the engine running, perform the ENGINE RUNNING PROCEDURES to test the windshield wiper, brakes, parking brake, hoist operation, and any other items recommended in the operator's manual.

- If any item is marked NR, ensure to fill in the Repair Date/Repairer's Initials once the necessary repairs are completed.

In case the tractor is deemed unsafe, it is crucial to report the condition immediately to the supervisor. The tractor should not be operated until it has been repaired and deemed safe. Remember, this checklist is not only a formality but a critical step in preventive maintenance and ensuring the safety of the operator and those around.

Obtain Answers on Tractor Checklist

-

What is the purpose of the Tractor Pre-Use Checklist?

The Tractor Pre-Use Checklist is designed to ensure safety and operational efficiency before the tractor is used. By completing this checklist, operators can identify any issues that require attention, thereby preventing accidents and equipment failure. It covers a range of inspection items from tire inflation and engine oil levels to safety equipment and operational controls. The checklist aims to catch potential problems that could compromise the safety of the operator or the functionality of the tractor.

-

How often should the Tractor Pre-Use Checklist be completed?

This checklist should be completed before each use of the tractor. Regular pre-use inspection helps in maintaining the tractor in good working condition and ensuring safety standards are met. It's crucial for catching issues early and addressing them before they lead to more significant problems or safety hazards during operation.

-

What should be done if an item on the checklist is marked as "Needs Repair" (NR)?

If any item on the checklist is marked under "Needs Repair" (NR), it indicates that the specific item inspected does not meet the safety or operational standards and requires immediate attention. The following steps should be taken:

- Report the condition immediately to a supervisor.

- Do not operate the tractor until the repair has been completed and the issue has been resolved.

- Ensure that the repair is documented in the "Repair Date/Repairer's Initials" section of the checklist once completed.

This process helps in maintaining a record of maintenance and ensures that all equipment is safe and functional before use.

-

Who is responsible for completing the Tractor Pre-Use Checklist?

The responsibility for completing the Tractor Pre-Use Checklist typically falls on the tractor operator or the individual who will be using the tractor. It is part of their duty to ensure the machine is safe and ready for operation. However, it's also crucial for supervisors to oversee and ensure that these checks are conducted properly and that any issues are addressed promptly.

-

Is it necessary to complete the checklist if the tractor was just inspected the day before?

Yes, it is necessary to complete the checklist even if the tractor was inspected the day before. Issues or safety hazards can arise between uses, and environmental factors can affect the tractor's condition overnight. Completing the checklist before each use ensures that any new or recurring issues are identified and addressed to maintain a high level of safety and operational efficiency.

Common mistakes

Filling out a Tractor Checklist is essential for the safety and maintenance of agricultural equipment. However, individuals can make several common mistakes during this process. Recognizing and avoiding these errors can contribute to the safer and more efficient operation of tractors.

Not reading the operator's manual carefully. Every tractor has its specifications and requirements for maintenance and safety checks. Without thoroughly understanding the manual, it's easy to overlook critical details in the checklist.

Failing to check the tractor at the recommended times. Inspections should be done regularly and according to the guidelines established in the checklist. Skipping or delaying inspections can lead to missing important maintenance issues.

Incompletely filling out the checklist. Sometimes, individuals rush through the checklist or leave sections blank if they are unsure about the condition of a particular item. This defeats the purpose of the checklist, which is designed to ensure every part of the tractor is in proper working condition.

Ignoring small issues. When people encounter minor problems, such as slight cuts on tires or small leaks, they might mark them as "OK" thinking they're not significant. However, these "minor" issues can escalate into major safety hazards over time.

Not reporting problems immediately. If the checklist uncovers a problem that needs repair, it should be reported to a supervisor right away. Delaying this communication can put the tractor's operator and others at risk.

Forgetting to verify the repairs. Once repairs are reported and supposedly completed, the checklist should be re-visited to ensure the maintenance was performed correctly. Skipping this step might mean the tractor is still not safe to use.

In addition to these common mistakes, there are several best practices that can enhance the effectiveness of completing a Tractor Checklist:

Always use a pen to fill out the checklist. This makes changes or tampering more difficult, ensuring the integrity of the inspection history.

Make sure the checklist is accessible to all operators. It should be stored in a place where it can be easily found and used by anyone who needs to inspect the tractor.

Review the checklist periodically for updates. Sometimes, manufacturers may update the recommended checks or procedures, so it's important to make sure the checklist is current.

Rigorously following the procedures outlined in a Tractor Checklist is crucial for the longevity of the machinery and the safety of its operators. By avoiding common mistakes and adhering to best practices, individuals can ensure their tractors are safe and well-maintained.

Documents used along the form

When maintaining and operating a tractor, it's crucial to have access to the right forms and documents that ensure safety, compliance, and effective management. The Tractor Pre-Use Checklist form is just the starting point. Alongside this essential checklist, there are several other documents often used to maintain the health, safety, and operational effectiveness of tractors and other heavy machinery. Below is a list of relevant documents that supplement the Tractor Checklist form.

- Maintenance Log: Records all maintenance activities on the tractor, including dates, descriptions of the service performed, and the name of the service provider. This ensures a historical record of all maintenance work for future reference.

- Operator's Manual: Provides detailed information on how to operate the tractor safely and efficiently, including specifications, controls, and proper operating procedures.

- Fuel Log: Tracks the amount of fuel used by the tractor, helping manage costs and schedule refueling.

- Incident Report: Used to document any accidents, breakdowns, or safety incidents involving the tractor, including details of the incident, any injuries, and steps taken afterward.

- Repair Orders: Issued for any repairs needed on the tractor, specifying the repair work to be done, parts required, and the assigned repair technician.

- Inspection Forms: Used for periodic safety and compliance inspections beyond the initial pre-use check, ensuring that the tractor remains in safe working condition over time.

- Equipment Rental Agreement: If the tractor is rented, this document outlines the rental terms, including duration, payment, and the responsibilities of both parties.

- Warranty Documents: Detail the manufacturer’s warranty coverage on the tractor, including what is covered and how long the warranty lasts.

- Training Records: Document the training history of operators, showing that they are qualified to operate the tractor safely.

- Insurance Policy: Outlines the insurance coverage on the tractor, including what damages or liabilities are covered.

Having these documents in order, alongside the Tractor Pre-Use Checklist, contributes to a comprehensive approach to tractor maintenance, operation, and safety. These forms and documents not only help in keeping detailed records but also play a crucial role in ensuring legal compliance, operational efficiency, and safety in agricultural or construction settings where tractors are frequently used.

Similar forms

Vehicle Maintenance Log: Similar to the Tractor Checklist form, a Vehicle Maintenance Log is primarily used to record regular inspections, maintenance activities, and repairs of a vehicle. Both documents are crucial for ensuring that a vehicle is in proper working condition and safe for operation. They typically include sections for the date of inspection or maintenance, details of the inspected item or maintenance activity, the condition of the vehicle (or specific parts), and the initials of the person conducting the inspection or maintenance. The Tractor Checklist emphasizes pre-use checks, whereas the Vehicle Maintenance Log covers a broader range of maintenance activities over time.

Equipment Safety Inspection Checklist: This document shares many similarities with the Tractor Checklist form in terms of structure and purpose. Both are designed to ensure that equipment is safe and ready for use by conducting thorough inspections before operation. Specific items, like fluid levels, structural integrity, and the presence and condition of safety features, are checked off as either satisfactory or needing repair (OK/NR). The primary difference lies in the scope, as an Equipment Safety Inspection Checklist can be used for a wide variety of machines beyond tractors, including industrial machinery and office equipment.

Pre-Trip Inspection Form for Commercial Vehicles: Common in the transportation and logistic sectors, this form bears resemblance to the Tractor Checklist by focusing on ensuring vehicles are safe and operational before hitting the road. Similar sections such as tire condition, engine checks, safety equipment, and signaling devices are reviewed to prevent breakdowns and accidents. While the Pre-Trip Inspection Form is specifically tailored for commercial vehicles like trucks and buses, both forms share the goal of proactive safety through routine checks.

Aircraft Pre-Flight Checklist: Although used in a different mode of transportation, the Aircraft Pre-Flight Checklist parallels the Tractor Checklist form in its emphasis on safety through meticulous inspection before use. Pilots check various aircraft components, including engines, controls, fuel levels, and emergency equipment, tagging them as okay or noting repairs needed, akin to the tractor's inspection process. Despite the contextual differences—tractors for ground operations and aircraft for flight—the underlying principle of ensuring operational integrity and safety before use unites these documents.

Dos and Don'ts

When filling out the Tractor Checklist form, ensuring accuracy and attention to detail is paramount for the safety of the operator and the effective maintenance of the tractor. Here are five essential things you should and shouldn't do:

Do:- Review the tractor's operator manual before conducting the inspection. This helps identify specific areas that require attention and ensures a thorough inspection.

- Ensure that the inspection is completed in a well-lit area to properly check all items on the checklist. Adequate lighting is crucial for identifying potential issues.

- Use the correct terminology and units when noting observations, especially when marking items as OK (Okay) or NR (Needs Repair). Consistency in language prevents misunderstandings.

- Report any items marked as NR (Needs Repair) immediately to the supervisor. Prompt reporting is key to addressing safety concerns and avoiding potential hazards.

- Sign and date the checklist after completing the inspection. This not only complies with record-keeping requirements but also ensures accountability.

- Never rush through the inspection process. Taking your time can be the difference between spotting a critical safety issue and missing it.

- Avoid skipping items, even if they seem insignificant. Each item on the checklist is included for safety and must be checked.

- Do not forget to check the fluid levels (engine oil and engine coolant) under the correct conditions according to the operator's manual. Incorrect levels can signal maintenance needs.

- Do not ignore minor issues, such as small cuts in tires or slight leaks. These can escalate into major problems if not addressed.

- Lastly, never operate the tractor if any critical safety features are marked as NR (Needs Repair) until the necessary repairs are completed.

Misconceptions

There are several misconceptions about the Tractor Checklist form that can lead to misunderstandings about its purpose and how it should be used. It's important to clarify these points to ensure that the tractor inspection process is carried out effectively and safely.

It's only for large farms: Some people believe the Tractor Checklist form is only necessary for large farming operations. However, any size farm or operation that uses a tractor can benefit from this checklist to ensure safety and proper maintenance.

It's a one-time task: Another common misconception is that the checklist needs to be completed only once. In reality, the checklist should be used before each use of the tractor to ensure it is in safe working condition.

It replaces regular maintenance: Using the Tractor Checklist does not mean regular maintenance can be ignored. The checklist is a supplement to regular maintenance, not a replacement.

It's too time-consuming: Some may think completing the checklist takes too much time. However, this step is crucial for preventing accidents and can ultimately save time by identifying potential issues before they cause breakdowns.

Only the operator needs to know how to use it: While the operator should indeed know how to complete the checklist, it's beneficial for anyone involved in the tractor's operation or maintenance to understand it. This ensures that safety and maintenance standards are universally recognized and upheld.

It's unnecessary if the tractor is new: New tractors can also have issues that could be caught by a thorough inspection. No matter the age of the tractor, using the checklist is a good practice.

It's only about checking the engine: The checklist covers much more than the engine, including safety features, tires, lights, and more to ensure the tractor is safe and fully operational.

If everything looks okay, there's no need to check: Visual inspections are important, but some issues may not be immediately apparent without following the specific steps in the checklist. It's crucial to go through each item to ensure all parts of the tractor are functioning correctly.

By addressing these misconceptions, users of the Tractor Checklist form can more accurately appreciate its importance in maintaining a safe and efficient working environment for tractor operation.

Key takeaways

Ensuring safety and operational efficiency, the Tractor Checklist form is an essential tool for individuals responsible for the daily use and maintenance of tractors. Below are four key takeaways about filling out and using this crucial form effectively:

- Comprehensive Pre-Use Inspection: Before using the tractor, a thorough pre-use inspection is mandatory. This inspection includes verifying the condition of the windshield, checking the tires for proper inflation and signs of wear, ensuring the three-point hitch assembly is securely fastened, and verifying fluid levels such as engine oil and coolant are at appropriate levels. Additionally, the presence and condition of the PTO master shield and hitch pins should be checked.

- Routine Maintenance Checks: The checklist prompts users to ensure the fuel supply is adequate and securely fastened, the handrail, steps, and platform are clean and in good condition, and if applicable, that the ROPS (Roll-Over Protective Structure) is correctly positioned. These checks are crucial for not only the operator's safety but also for the longevity of the tractor.

- Ensuring Operational Functionality: Functions such as turn signals, seat adjustment, the functionality of gauges and instruments, horn, brakes, parking brake, and hoist operation are to be tested. This section ensures that all the essential functions of the tractor are in working order before use, minimizing the risk of accidents due to equipment failure.

- Reporting and Addressing Issues: One of the most critical aspects highlighted by the form is the immediate reporting and fixing of any issues discovered during the inspection. If the tractor or any attached equipment is found to be unsafe, the condition must be reported immediately to a supervisor and repaired. This ensures that all equipment is in safe working condition, thereby protecting the operator and others in the vicinity.

Adhering to the Tractor Checklist form not only ensures compliance with safety regulations but also promotes a culture of proactive maintenance and safety awareness among operators and supervisors.

Popular PDF Forms

Itinerary Builder - Helps Drexel Club Sports thoroughly prepare for travel, detailing everything from departure times to emergency contacts.

Update Beneficiaries - Policyholders are cautioned not to send the actual insurance policy document but only the completed form for processing.